Transmission canal with diphasic heat sink

A heat dissipation device and transmission flow technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve the problems of increasing the frictional resistance of liquid return, drying the evaporator, limiting heat dissipation capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

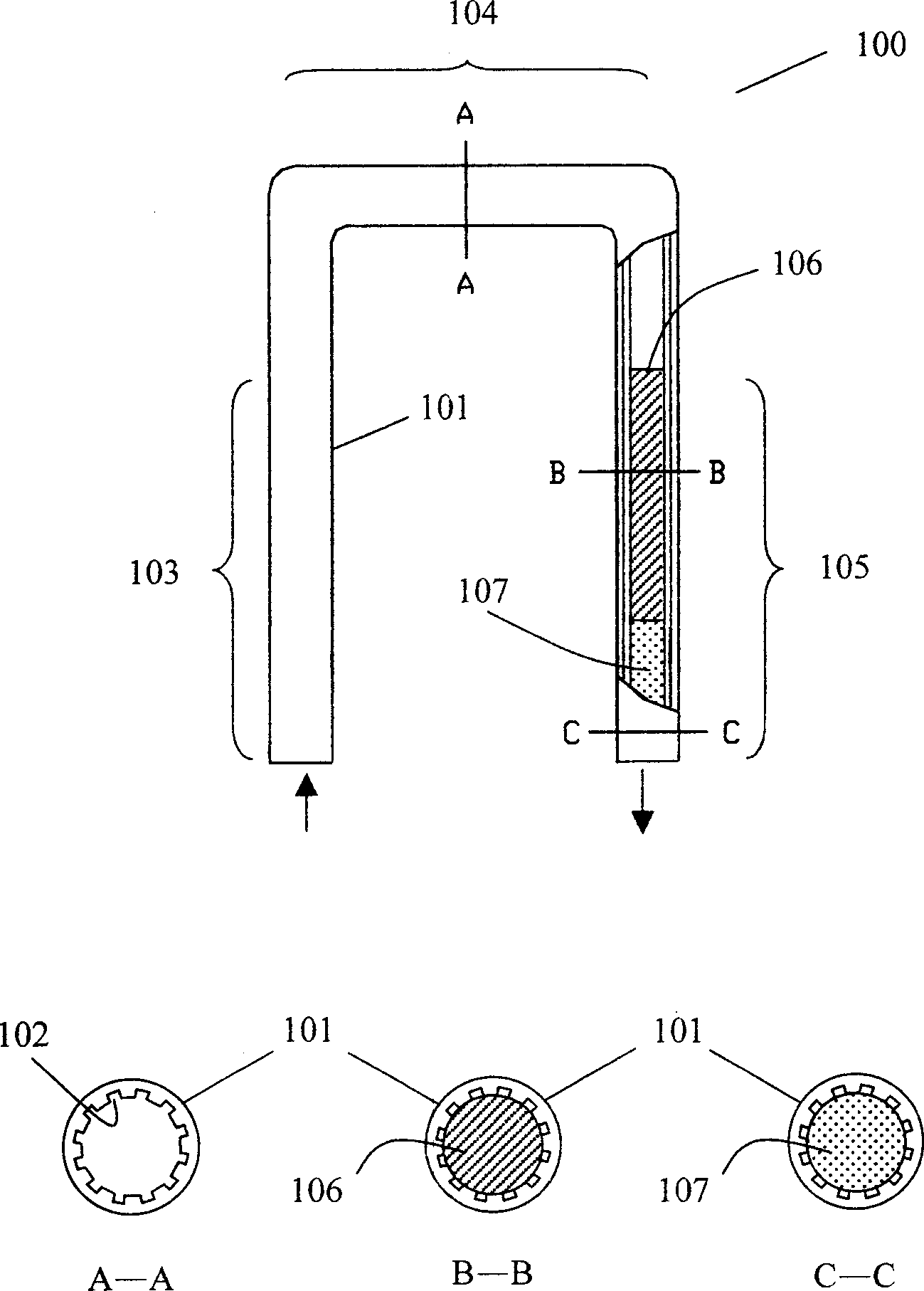

[0017] image 3 Disclosed is a cross-sectional view of a first embodiment of a transmission channel suitable for a two-phase heat dissipation device proposed by the present invention. The transmission channel 100 is divided into three sections: a steam channel 103 , a condensation channel 104 , and a liquid return channel 105 . On the inner wall of the metal tube 101, there is a ring groove micro-flow channel 102, which can be made on the tube wall when the tube is extruded and formed. A microchannel is defined herein as a long fluid channel with a hydraulic diameter of less than 500 μm, and its cross-sectional shape can be V-shaped, triangular, square, trapezoidal, wavy or other shapes. A plug 106 is used to plug the tube core area of the liquid return flow channel 105 to form a ring of closed micro channel arrays. The above-mentioned plug 106 can be made of metal, plastic, or other heat-resistant materials. The bottom corners of the grooved micro-channel (as shown in se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap