Assembly type multifunctional sensing device and method for making same

A sensor device and multi-functional technology, applied in the direction of instruments, analytical materials, etc., can solve the problems of restricting wide application, key technologies still need to be developed, and low throughput, and achieve the effect of reducing manufacturing costs, low cost, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

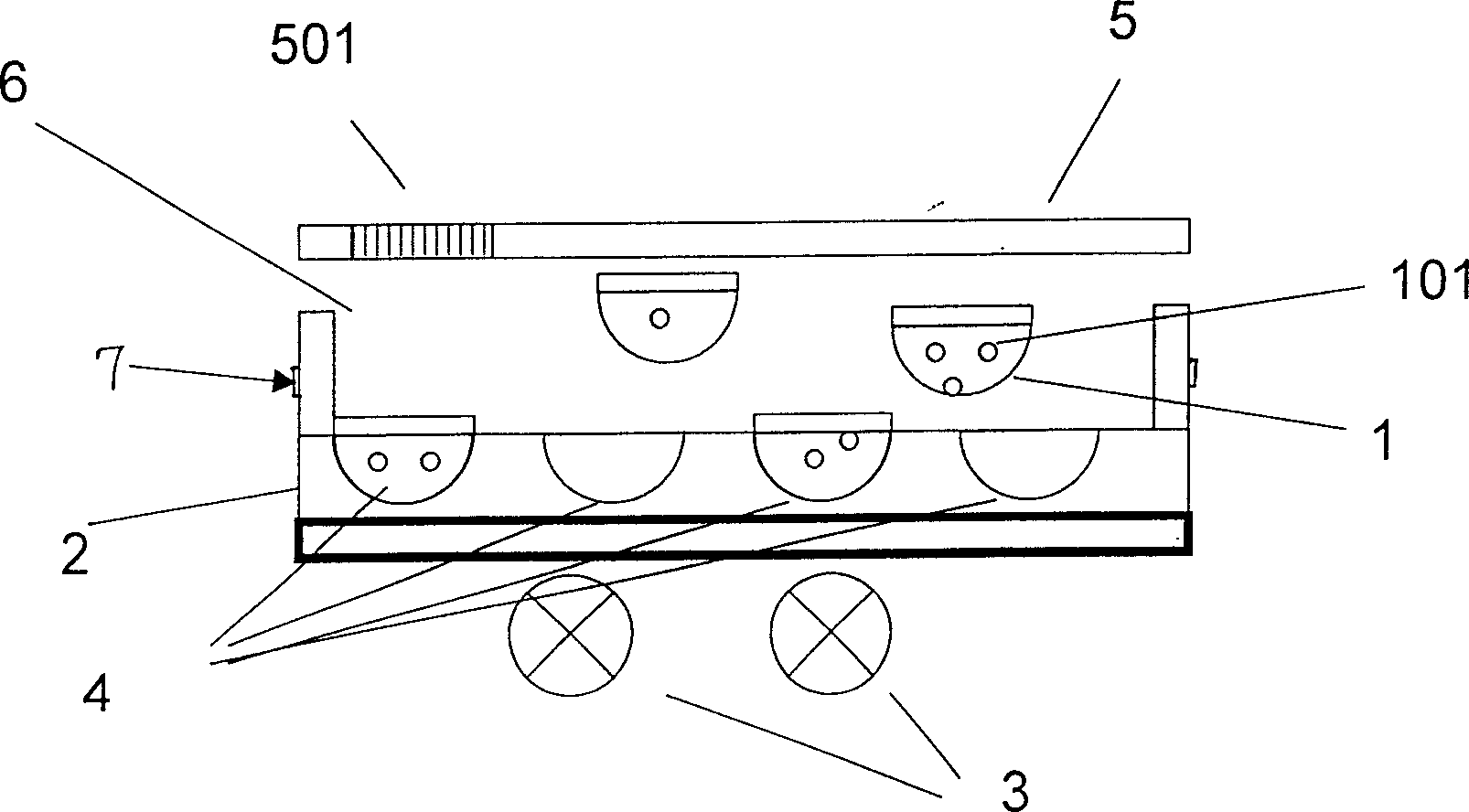

[0028] like figure 1 shown.

[0029] A component multifunctional sensor device, including a sensing functional unit 1, a sensing transduction platform 2, a magnetic force generating device 3, a cover plate 5, and an auxiliary unit 7, and the sensing functional unit 1 is installed on the sensing transduction platform 2 In the arrayed potholes 4, the magnetic force generating device 3 is located under the sensing transduction platform 2; Particles 101, the surface of which is connected with sensing and sensitive materials, the size of the sensing functional unit 1 is between 20 nanometers and 1 cm, and a cover plate 5 with an injection hole 501 is installed on the upper part of the sensing functional unit 1, the cover plate 5 Together with the sensing and transducing platform 2, a transducing space 6 is formed. The sensing transduction platform 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com