Two-wheeled motor vehicle

A technology for automatic two-wheeled vehicles and rear wheels, which is applied to bicycle accessories, bicycle control systems, axle suspension devices, etc. power, and the effect of improving design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

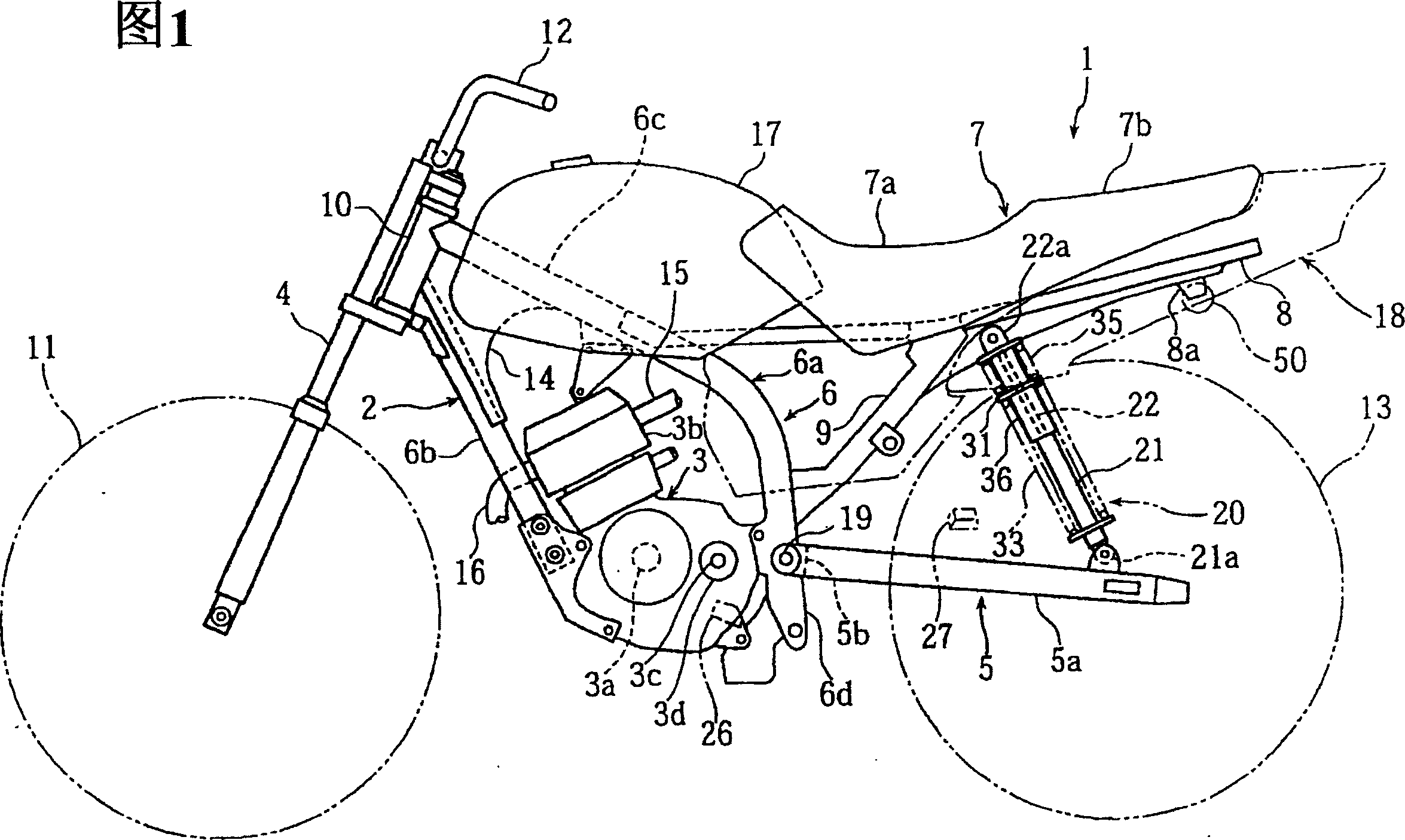

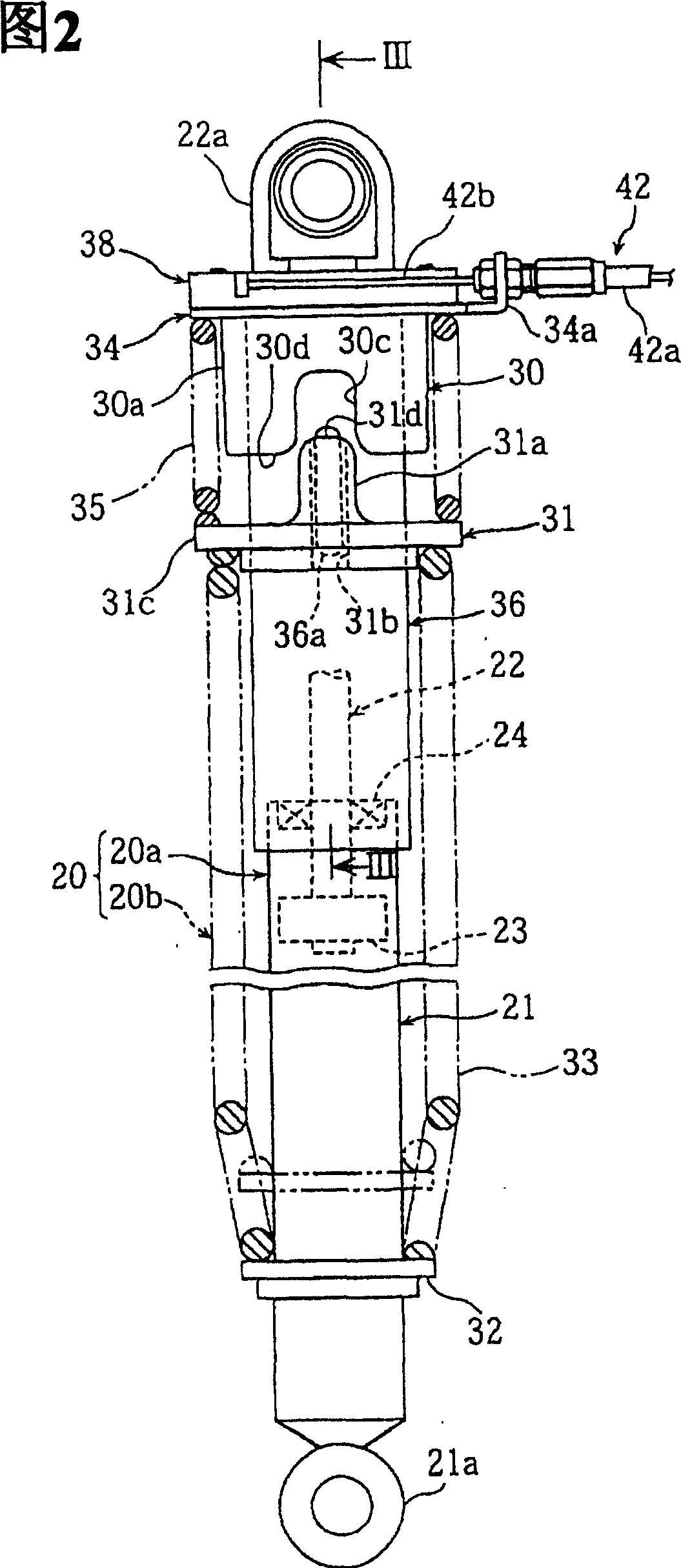

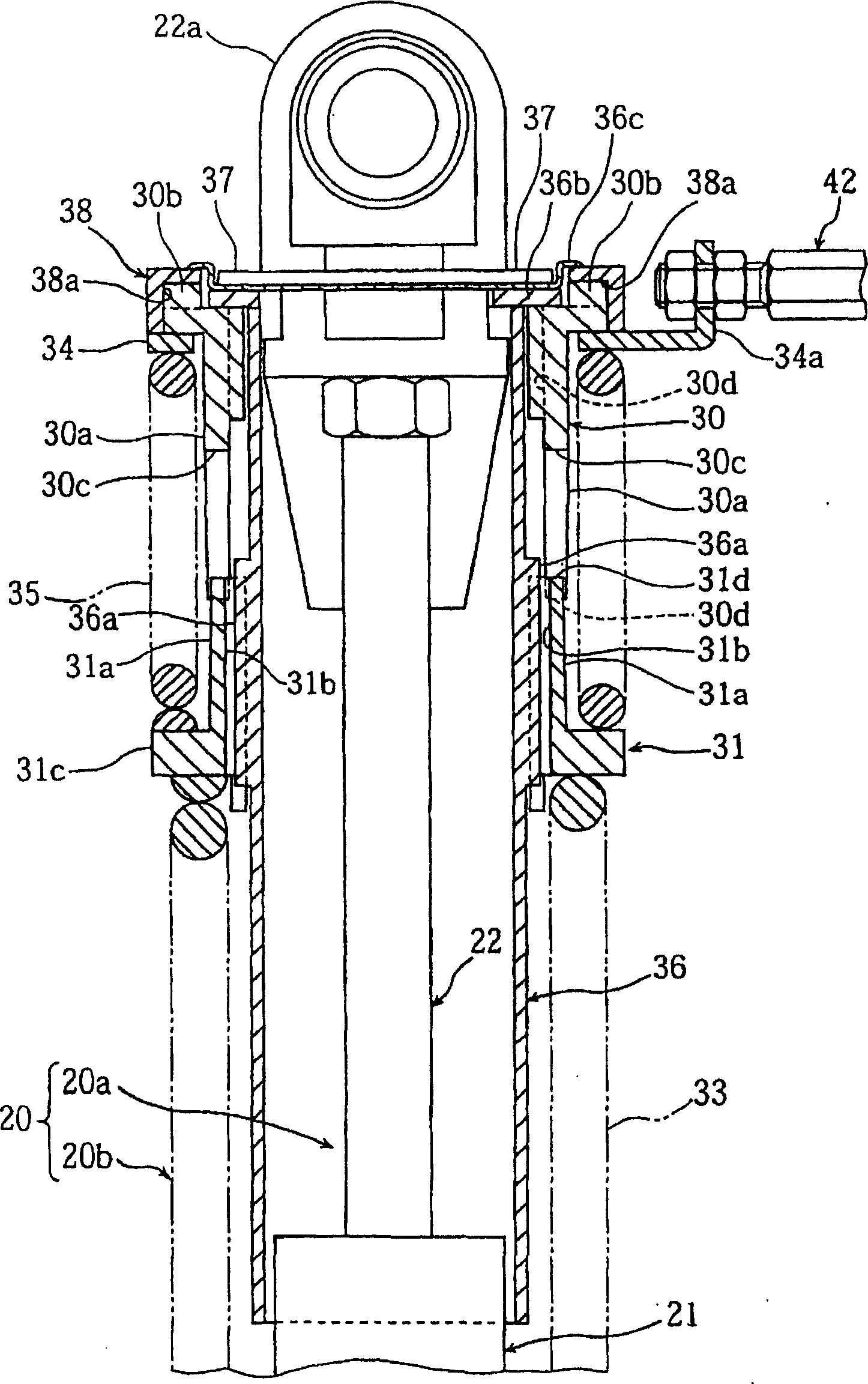

[0061] Figure 1~ Figure 13 It is used to explain the motorcycle according to the first embodiment of the present invention; FIG. 1 is a side view of a motorcycle provided with a rear wheel buffer device, and FIG. 2 is a front view of a buffer, image 3 It is a cross-sectional view of the spring characteristic switching mechanism of the buffer (the III-III line cross-sectional view of FIG. 2 ), and FIG. 4 is a top view of the operating part of the switching mechanism, Figure 5 is a partial sectional view of the operating part, Figure 6 is a perspective view of the buffer, Figure 7 is a perspective view of the dust cover, Figure 8 is a perspective view of the middle spring bracket part, Figure 9 is the perspective view of the cam, Figure 10 is the perspective view of the upper spring support, Figure 11 is the perspective view of the annular plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com