Injection molding production method of conic transparent parts

A technology of injection molding and manufacturing methods, which is applied in the field of injection molding and manufacturing of plastic products, can solve the problems of low yield and achieve the effects of improving production efficiency, prolonging the holding time, and prolonging the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

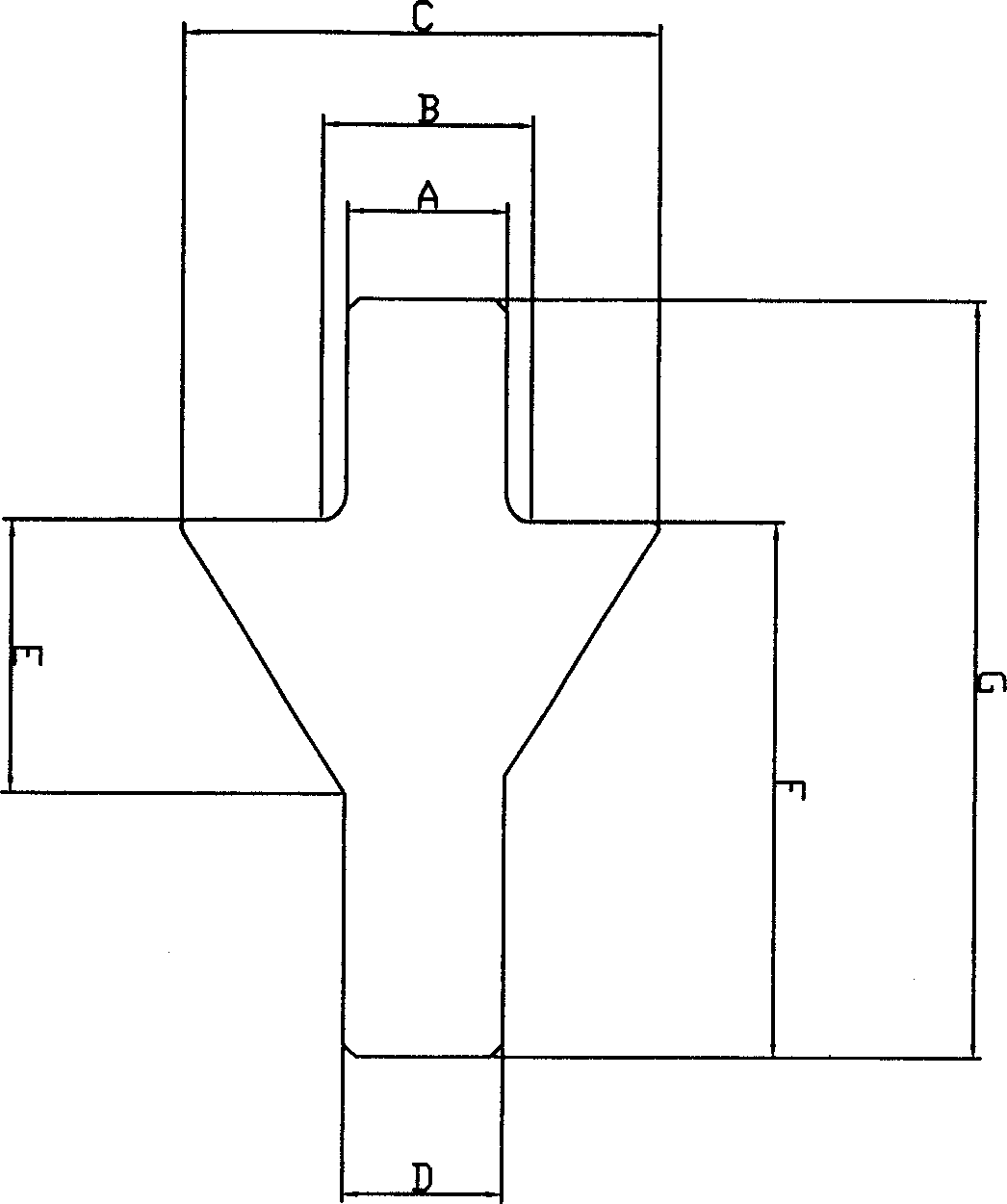

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018]

Product design size

Dimensions (mm)

Tolerance(mm)

A

φ18

±1

B

φ24

±1

C

φ83

±1

D

φ18

±1

E

34

±1

F

57

±1

G

86

±1

[0019] The above antenna can be injection molded using the following process parameters.

[0020] a. A large-diameter main sprue is used on the mold, and the diameter of the main sprue is 300% to 400% of the conventional diameter; the diameter of the main sprue in this example is 16mm.

[0021] b. Control the injection speed to be 20%-30% of the conventional speed; the specific speed can be 3-5mm / s;

[0022] c. Keep the pressure for 90-100 seconds under the pressure of 20-25 Pa / cm2 after injection;

[0023] d. After holding the pressure, cool ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap