Efficient and energy-saving coal gangue brick firing system

A high-efficiency, energy-saving, coal gangue technology, applied in combustion methods, combustion equipment, clay products, etc., can solve the problems of increasing the energy consumption of coal gangue brick burning, not meeting environmental protection requirements, increasing economic expenses, etc., to prevent burning The effect of uneven, improved efficiency, improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

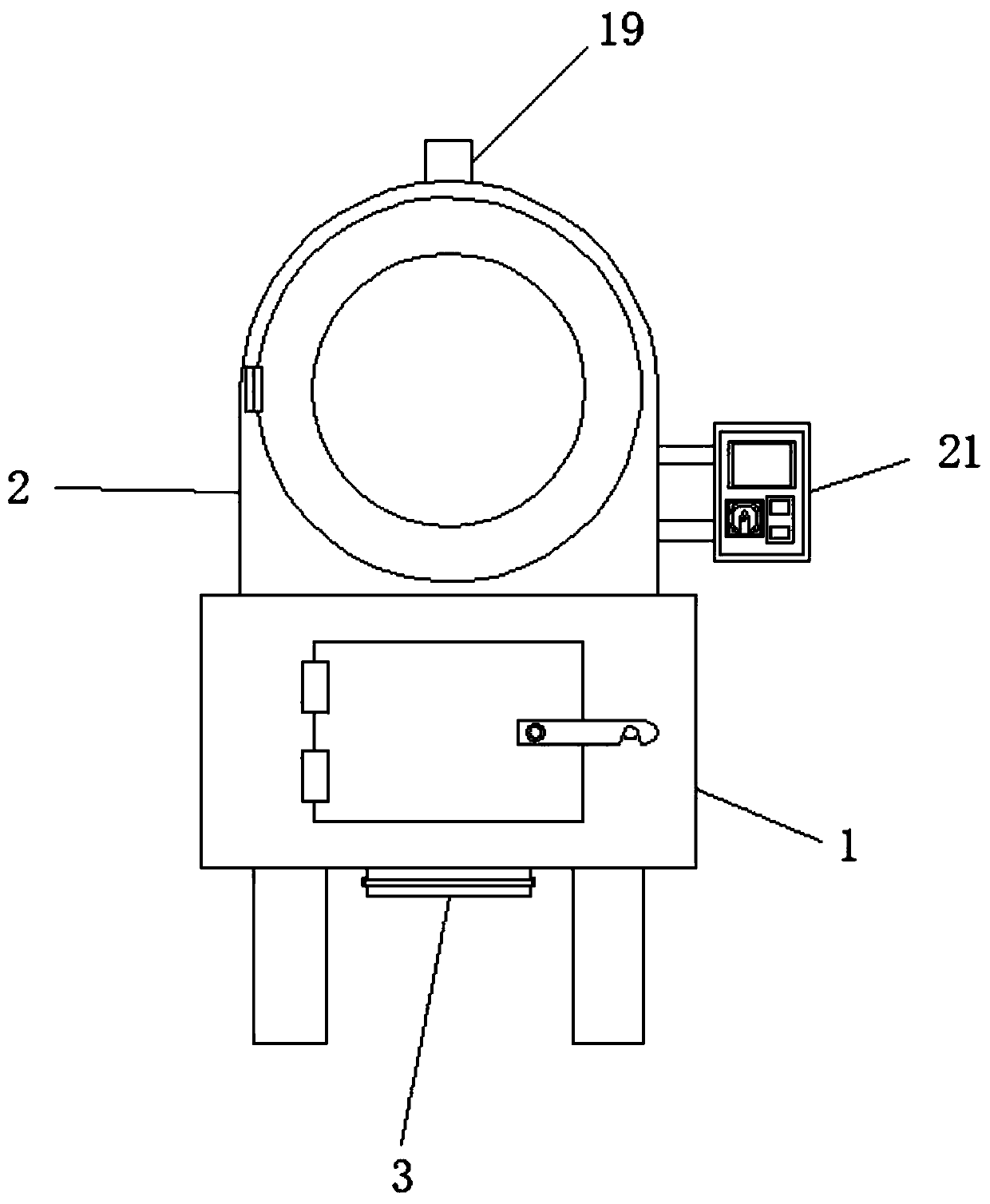

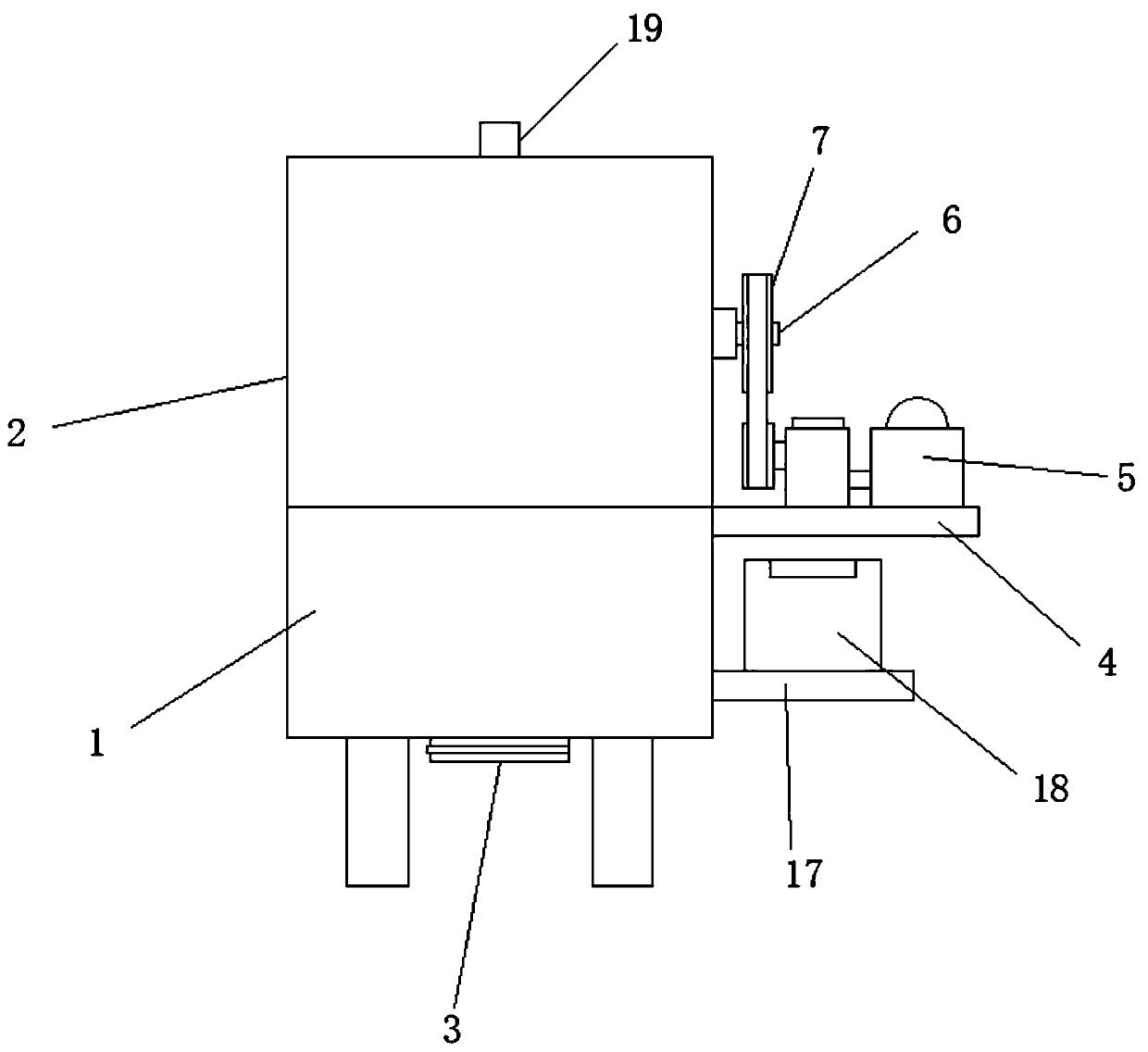

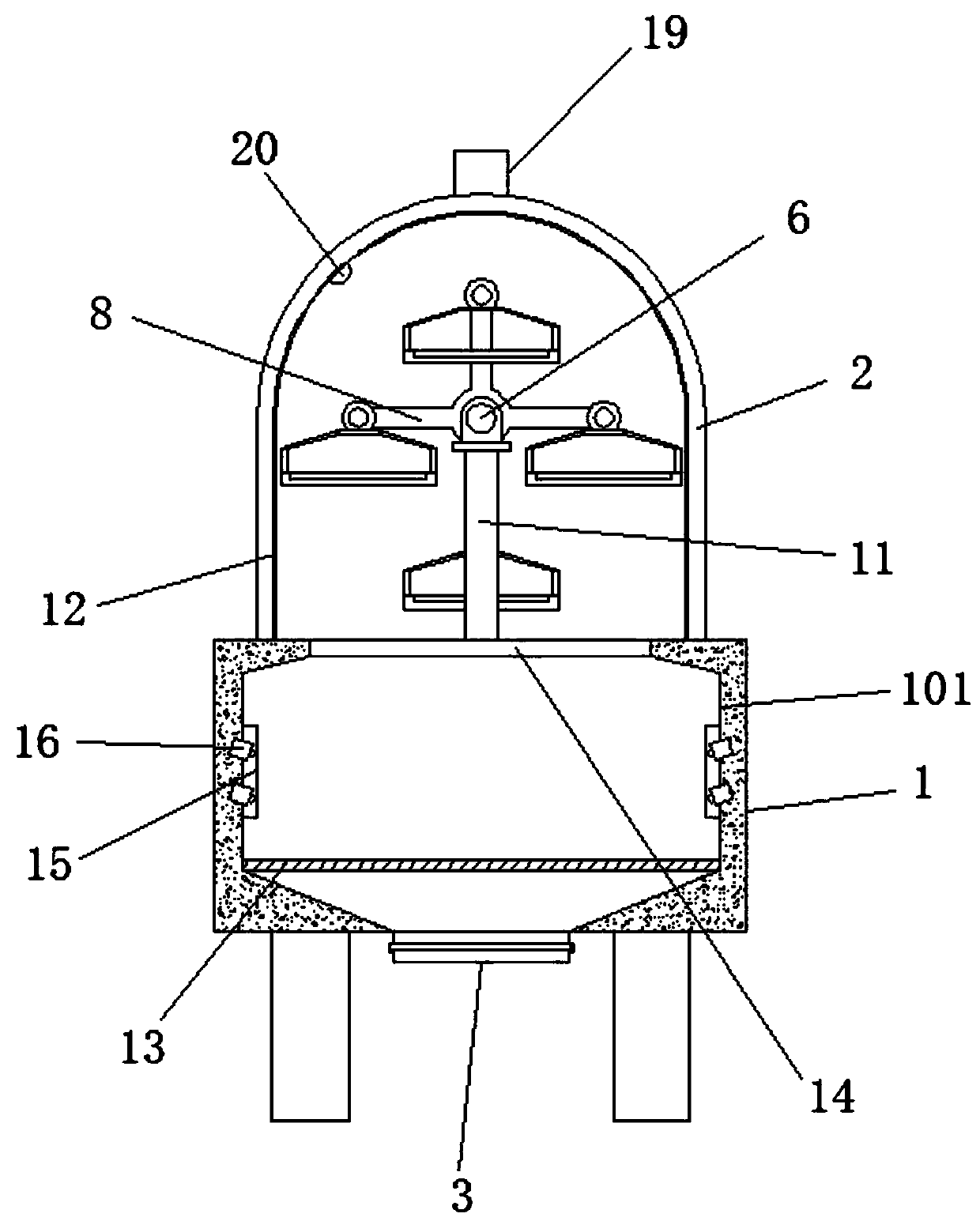

[0029] Such as Figure 1-7 As shown, the present invention provides a technical solution: a high-efficiency and energy-saving coal gangue brick firing system, including a heating furnace 1, a firing furnace 2, a slag discharge pipe 3, a through pipe 14 and a chimney 19, and the firing furnace 2 is arranged on the top surface of the heating furnace 1, and the bottom of the inner cavity of the firing furnace 2 is connected to the top of the inner cavity of the heating furnace 1 through a through pipe 14. A slag discharge pipe 3 is installed at the bottom of the firing furnace 2, and the firing A chimney 19 is inserted on the top surface of the furnace 2, a first fixed plate 4 is installed on the side wall surface of the heating furnace 1, a driving mechanism 5 is installed on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap