El display device and producing method thereof

An electroluminescent display and device technology, applied in the direction of electroluminescent light sources, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the complex manufacturing process, the degradation of device brightness and color purity, and the unfavorable light-emitting function of the organic light-emitting layer Impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

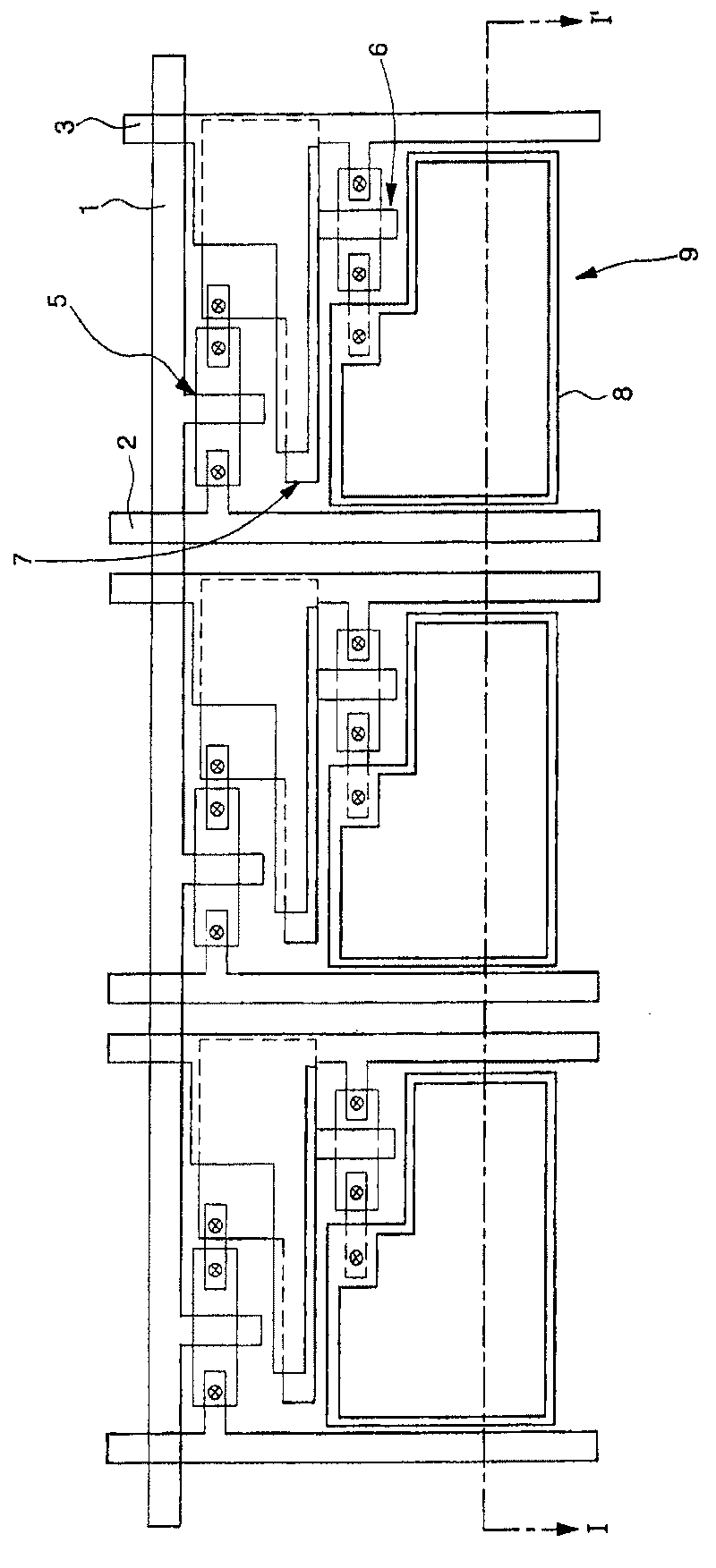

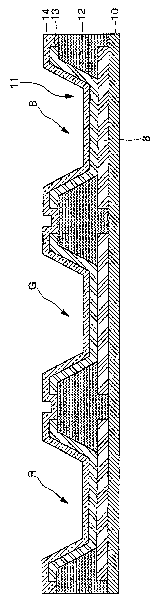

[0036] The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

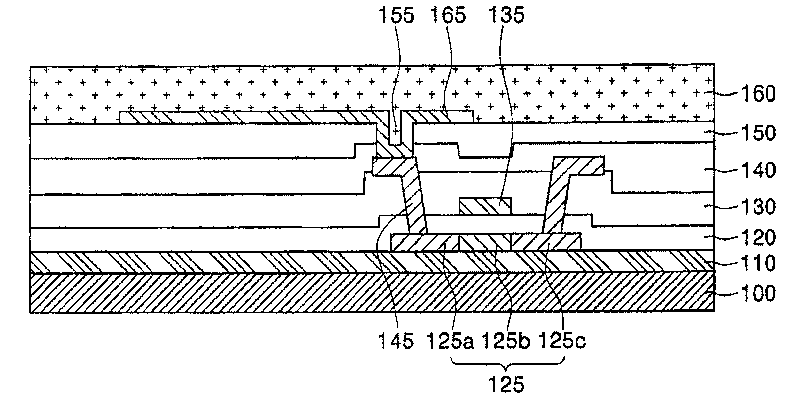

[0037] Figure 3A to Figure 3C is a sectional view for explaining an EL display device and a method of manufacturing it according to an exemplary embodiment of the present invention.

[0038] refer to Figure 3A , providing a substrate 100 . A buffer layer 110 may be formed on the substrate 100 to prevent impurities from flowing out of the upper portion of the substrate 100 . The buffer layer 110 may be, for example, a silicon oxide layer, a silicon nitride layer, or a stack of silicon oxide and silicon nitride layers.

[0039] After forming the buffer layer 110, a polysilicon layer 125 may be formed on the buffer layer 110 by crystallizing amorphous silicon.

[0040] A gate insulating layer 120 may then be formed on the substrate 100 having the polysilicon layer 125 , and a gate electrode 135 may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com