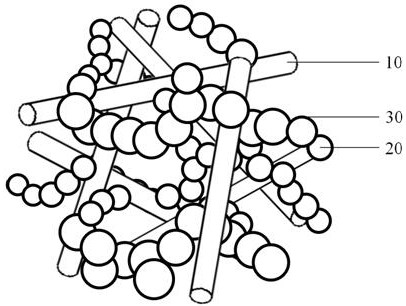

Airgel modified cotton fiber vacuum insulation panel core material and preparation method thereof

A technology of vacuum insulation board and modified cotton, which is applied in the field of thermal insulation materials, can solve the problems of shortening the preparation cycle, single structure and performance, etc., and achieve the effects of stability, structure stability and reduction of degassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

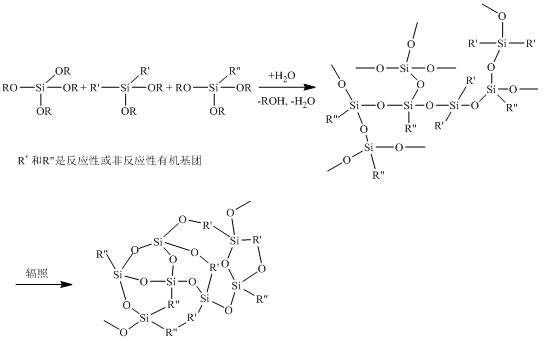

[0041] (1) Synthesis of silica sol: in parts by mass, mix 80 parts of ethyl orthosilicate, 20 parts of methacryloxypropyl trimethoxysilane, 400 parts of deionized water and 800 parts of ethanol, and use mechanical stirring The way to make it through 12h of hydrolysis reaction to obtain silica sol, then soak 5 parts of glass wool in the silica sol, and stir for 2h;

[0042] (2) Sol-semi-gel transformation: Put the silica sol in a dark box, add 2.5 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 9 parts of styrene, and use mechanical stirring Mix it for 3 hours, slowly add ammonia water / ethanol solution with a mass ratio of 1:6, adjust the pH of the silica sol to 7.5, stir for 0.5 hours, and make it undergo a certain degree of polycondensation reaction to obtain a semi-gel with good fluidity ;

[0043] (3) Coating polymer layer: In a dark environment, irradiate the semi-gel with ultraviolet light for 30s, so that the methacryloxy group on the surface of the semi-gel and th...

Embodiment 2

[0049] (1) Synthesis of silica sol: In parts by mass, 50 parts of ethyl orthosilicate, 20 parts of methyltrimethoxysilane and 30 parts of acryloyloxytriisopropylsilane, 500 parts of deionized water and 1200 parts Mix ethanol, use mechanical stirring to make it undergo 18h hydrolysis reaction to obtain silica sol, then soak 8 parts of rock wool in silica sol, and stir for 2h;

[0050] (2) Sol-semi-gel transformation: Put the silica sol in a dark box, add 2 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 8 parts of acrylic acid, and use mechanical stirring Mix it for 3 hours, slowly add NaOH / ethanol solution with a mass ratio of 1:5, adjust the pH of the silica sol to 8.0, stir for 1.5 hours, and make it undergo a certain degree of polycondensation reaction to obtain a semi-gel with better fluidity;

[0051] (3) Coating polymer layer: In a dark environment, irradiate the semi-gel with ultraviolet light for 40s, so that the acryloxy group on the surface of the semi-gel and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com