Filtering equipment and cleaning method using ultrasonic cleaning

A filter device and ultrasonic technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve problems such as accumulated dirt and unsatisfactory cleaning efficiency, and achieve the effect of ensuring the filtration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

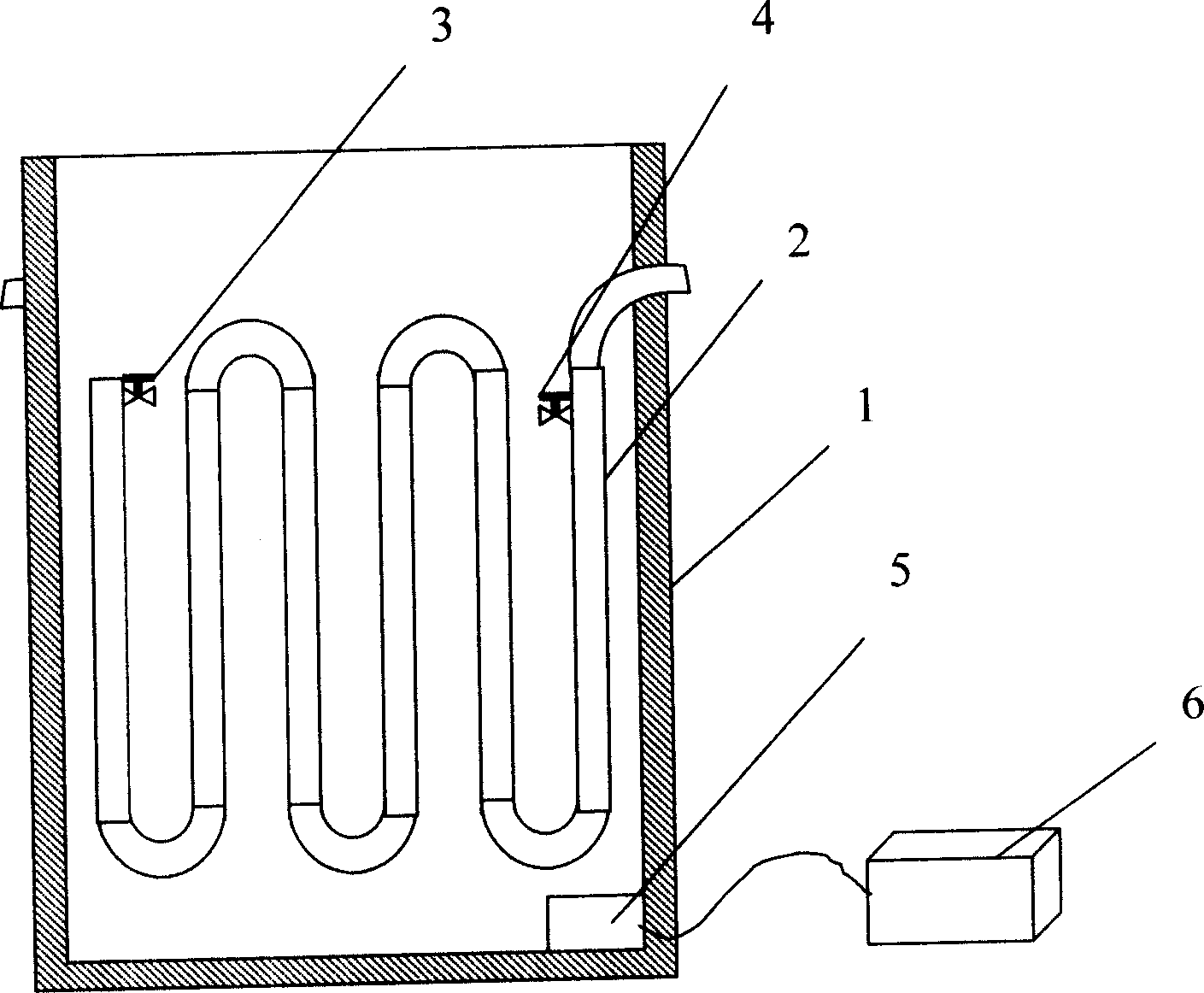

[0012] like figure 1 As shown, a filter device utilizing ultrasonic cleaning of the present invention is composed of a container 1 and more than one filter tube 2. The filter tubes 2 are connected in sequence, and the filter tubes 2 are all fixedly arranged on the In the container 1, the filter pipe 2 has a water inlet connected to the outside of the container 1, and the filter pipe 2 has a water outlet connected to the outside of the container 1, wherein the filter pipe 2 There is at least one second water inlet 3, the second water inlet 3 is set in the container 1, the second water inlet 3 is provided with a valve, the side wall of the container 1 An ultrasonic transducer 5 is fixedly arranged, and the ultrasonic transducer 5 is electrically connected with an ultrasonic power supply 6 .

[0013] In a preferred embodiment of the present invention, the filter pipe 2 has at least one second water outlet 4, the second water outlet 4 is arranged in the container 1, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com