Method for realizing Fanout design in PCB

A technology of implementation method and design information, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of poor PCB design consistency, inconvenient maintenance and management, low efficiency of Fanout design, etc., and achieve the effect of improving efficiency and flexible Fanout design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

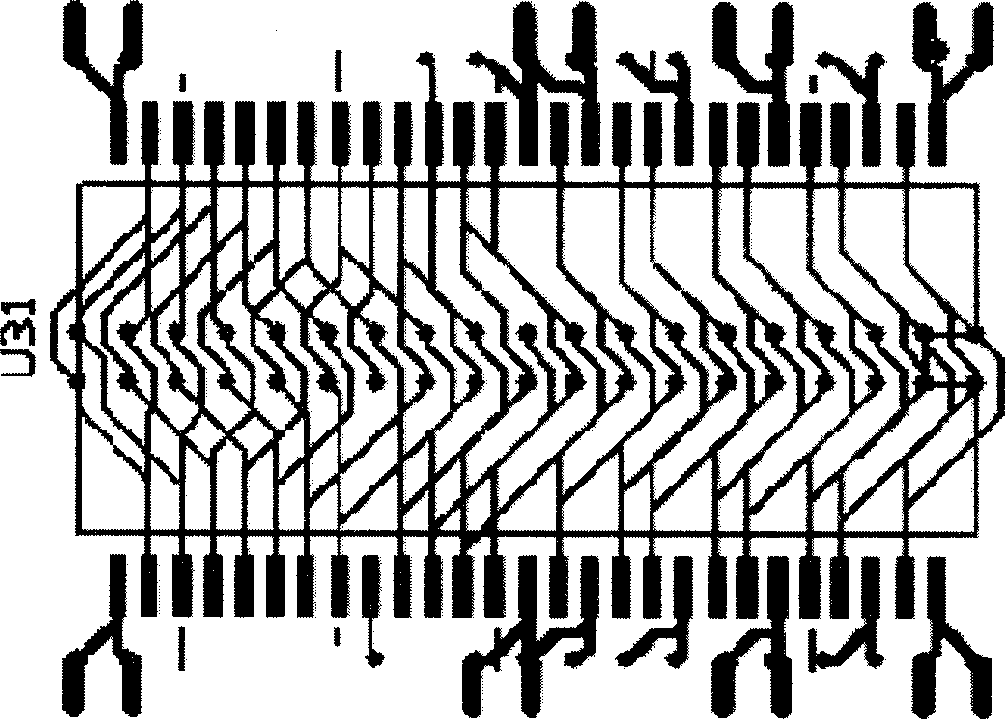

[0037] The core of the present invention is to save the Fanout design for each packaged device in the PCB design, so that it can be reused in the subsequent PCB design process, or when the Fanout design for the packaged device is needed again in other PCB design processes. The original Fanout design information, thereby effectively improving the efficiency of PCB design, especially improving the efficiency of Fanout design.

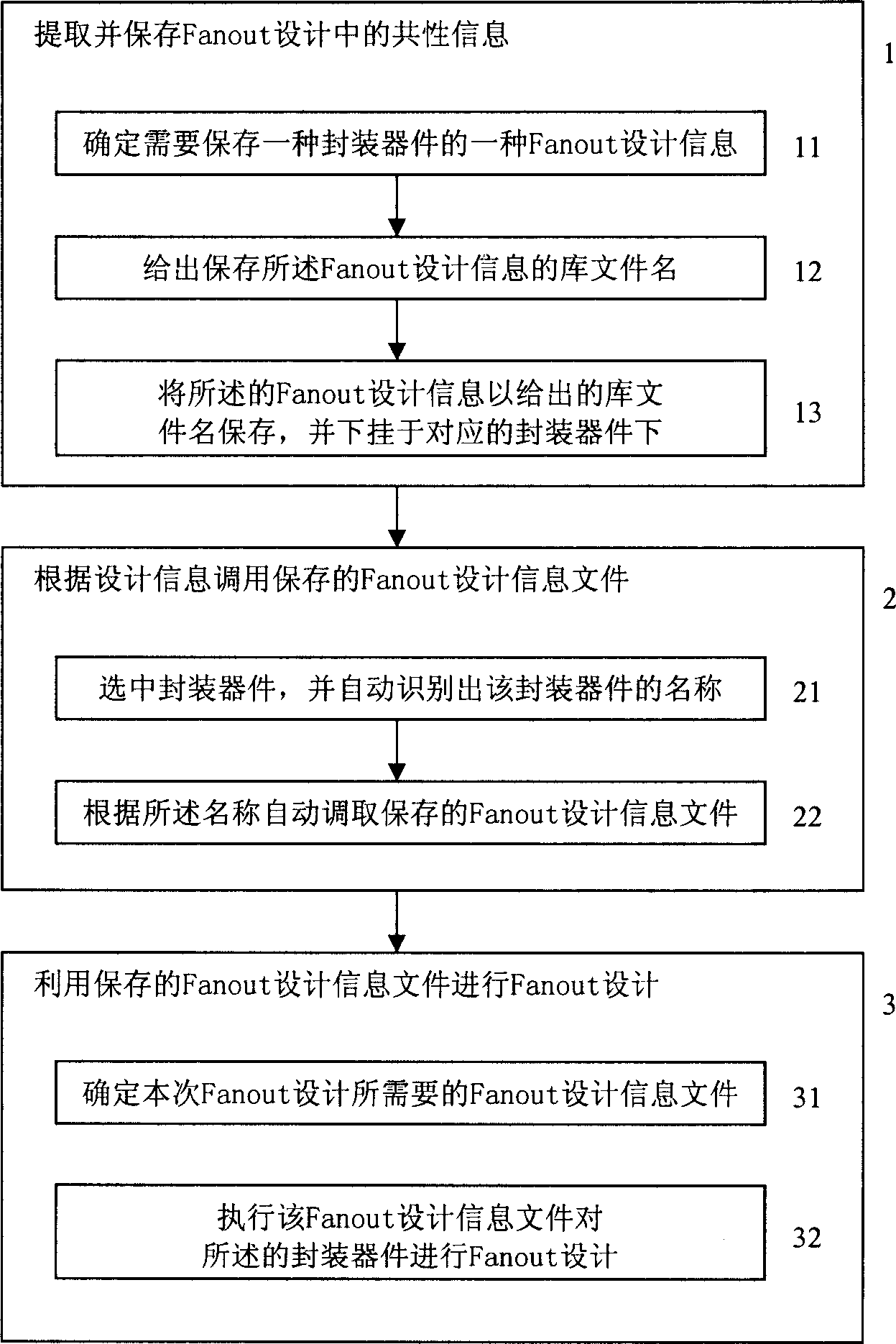

[0038] Below in conjunction with accompanying drawing, the implementation method of Fanout design in the PCB design of the present invention is described in detail, as figure 1 As shown, the method specifically includes the following steps:

[0039] Step 1: In order to reuse the design information in the Fanout design process, extract the common information in the Fanout design and save it;

[0040] Described step 1 further comprises the following steps:

[0041] Step 11: Determine that a fanout design information of a packaged device needs to be saved;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com