Coated cable

A cable and coating technology, applied in the field of cables, can solve the problems of insufficient flexibility, soft noise and soft pulley wear and pulley labor and time, and achieve the effect of prolonging life, preventing wear and preventing wear and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

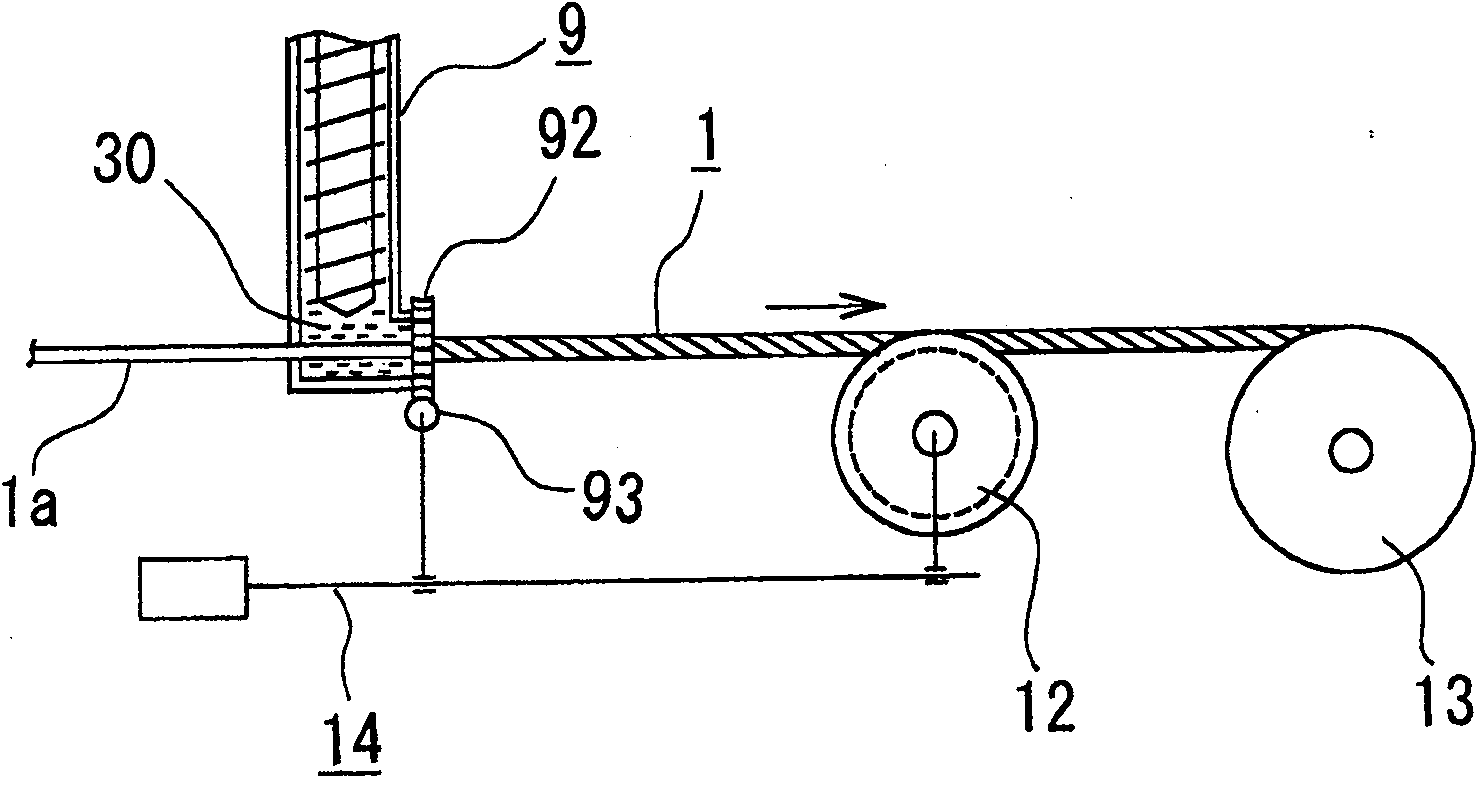

[0048] Figure 1 to Figure 9 A first embodiment of the covered cable of the present invention is shown.

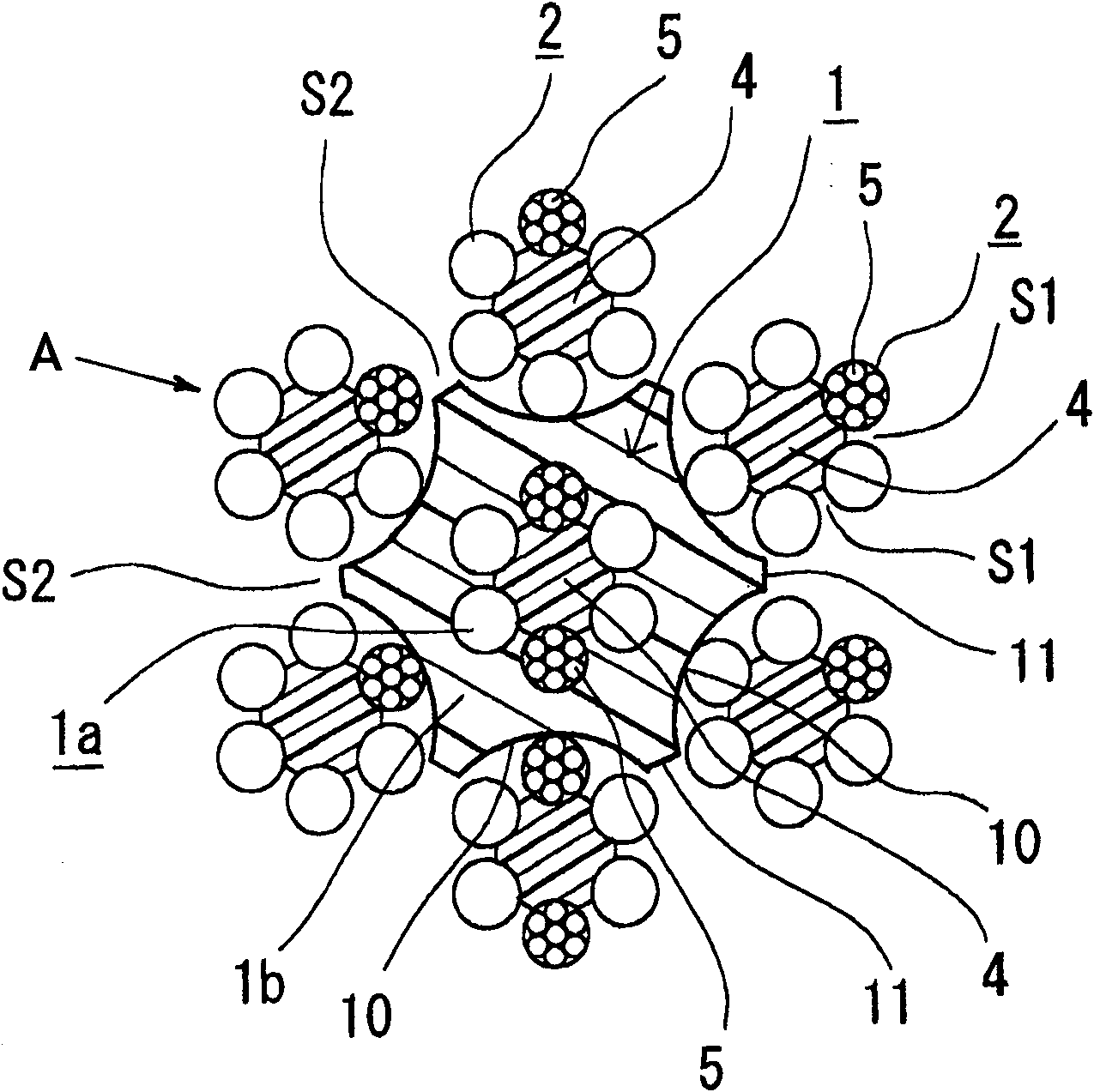

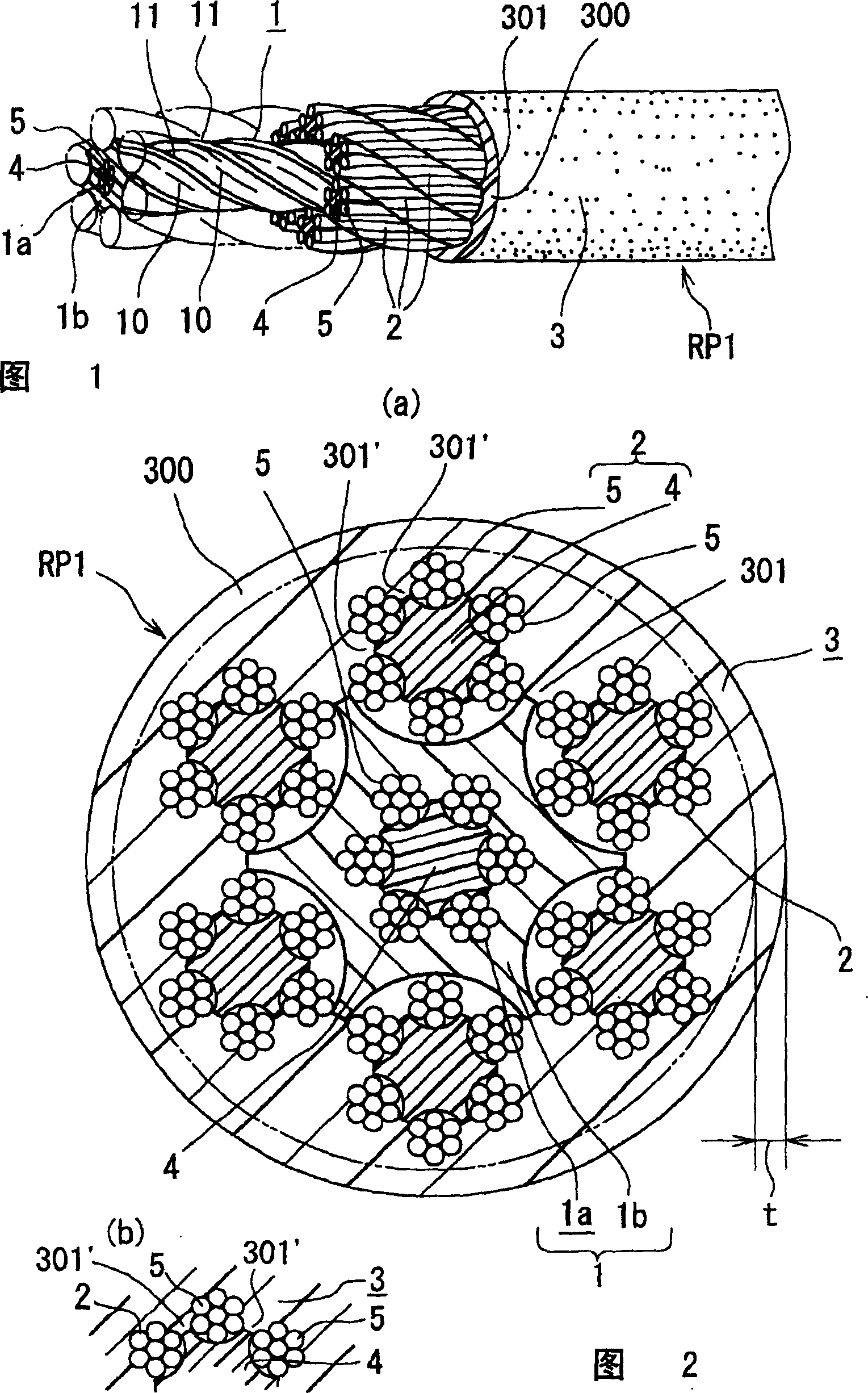

[0049] exist figure 1 In , reference numeral RP1 denotes the entire rope, which is composed of a single core rope 1 , a plurality of side members 2 , and an integral covering resin 3 applied so as to cover the side members 2 . In this example, the rope structure is 7×(6×7).

[0050] Corso 1 in Figure 4 2 shows the state of a single body, and the resin coating layer 1b is provided on the inner core cord main body 1a. The above-mentioned core cord main body 1a is constituted by a combined rope structure in which six twisted strands 5 are arranged and twisted around a rod-shaped or linear synthetic resin core 4 . In this embodiment, the side member 2 is constituted by a composite rope structure in which six twisted strands 5 are arranged and twisted around a synthetic resin core 4 .

[0051] The above-mentioned synthetic resin core 4 functions to improve the ductility ...

no. 2 approach

[0097] Figure 11 and Figure 12 A second embodiment of the cable of the invention is shown. In the rope of this embodiment, reference numeral RP3 denotes the whole, and is composed of a single core cord 1 , a plurality of side members 2 , and an integral covering resin 3 applied so as to cover the side members 2 . The rope structure is IWRC+8×S(18).

[0098]Since the core cable 1 of the second embodiment is the same as that already described, only the difference will be described, and a plurality of side members 2 (eight in the figure) are used. Each side member 2 is composed of a multi-layered twisted strand. The structure is arbitrary, but in this example, it is composed of 8×S(18), in other words, 8×S(a+9+9).

[0099] That is, nine relatively thin monofilaments 203 are arranged and twisted around the thick synthetic resin core 4 to form the inner layer 2a, and nine side monofilaments 202 with relatively thick diameters are arranged and twisted around the inner layer 2a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com