Connection rod member for bolt ball node steel lattice

A technology of bolt balls and steel grids, which is applied to building components, buildings, ceilings, etc., can solve the problems of inconvenient construction and installation, heavy grid steel structures, etc., and achieve the effect of weight reduction and flexible construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

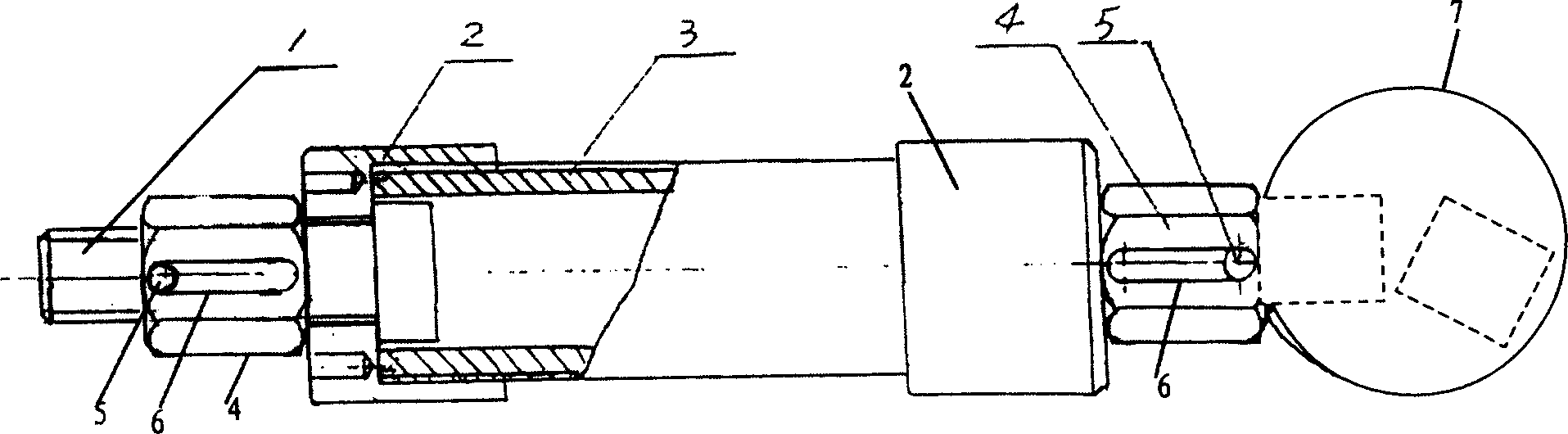

[0011] Such as figure 1 As shown, the present invention is a kind of connecting bar for bolt ball joint steel grid, which is composed of grid connecting pipe 3, bolt ball joint joint head and bolt ball 7, and described bolt ball joint joint head is composed of bolt 1, The sealing plate cone head 2 and the sleeve 4 are formed, and the bolt ball 7 is provided with more than two internal thread connection holes, the internal thread connection holes are matched with the bolts 1, and the grid connection The pipe 3 is fixedly connected with the sealing cone 2, the tail end of the bolt 1 is coaxially arranged in the sealing cone 2, and the middle section and the front end of the bolt 1 protrude from the Sealing plate cone head 2, the sleeve 4 is sleeved in the middle section of the bolt 1, the front end of the bolt 1 is connected with the bolt ball 7 through threads, wherein the grid connecting pipe 3 is composed of a steel-plastic composite structure pipe, and the end of the steel-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com