Optical disc driver tilting regulator

An optical disc drive, tilt adjustment technology, applied in beam guides, optical recording heads, head configuration/installation, etc., can solve problems such as difficulty in achieving optimal adjustment, and achieve improved precision, reliable adjustment, and position selection. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Referring to the accompanying drawings of the embodiment of the tilt adjustment device for optical disk drive produced by the present invention, the specific implementation manner of the present invention will be described in detail below.

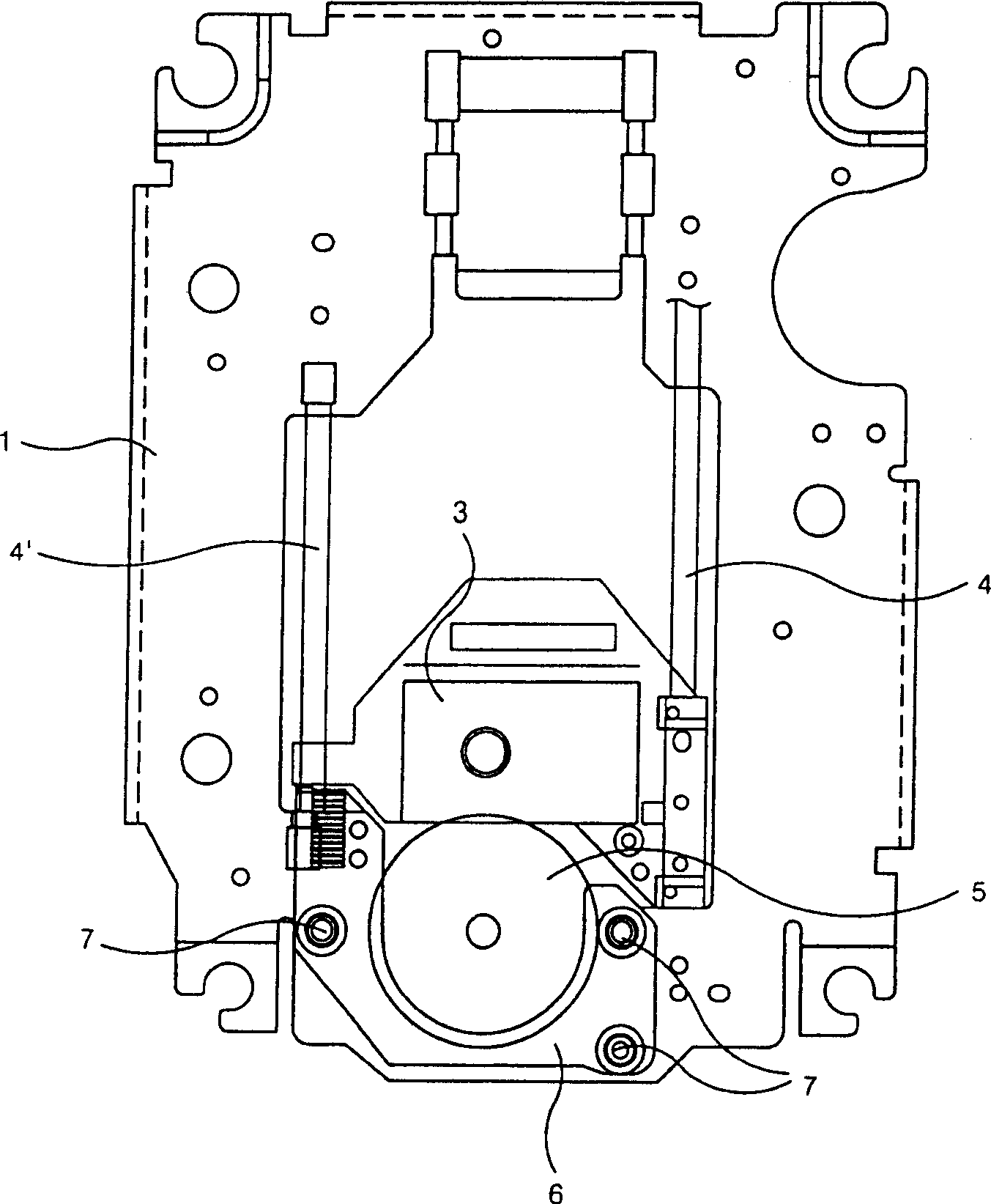

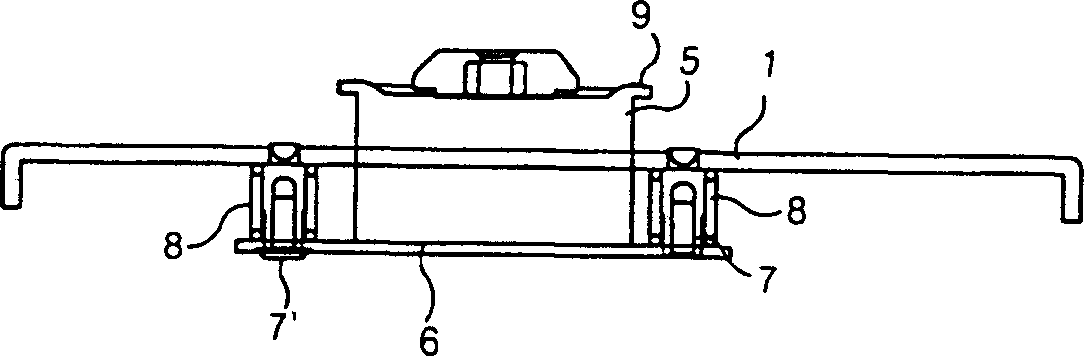

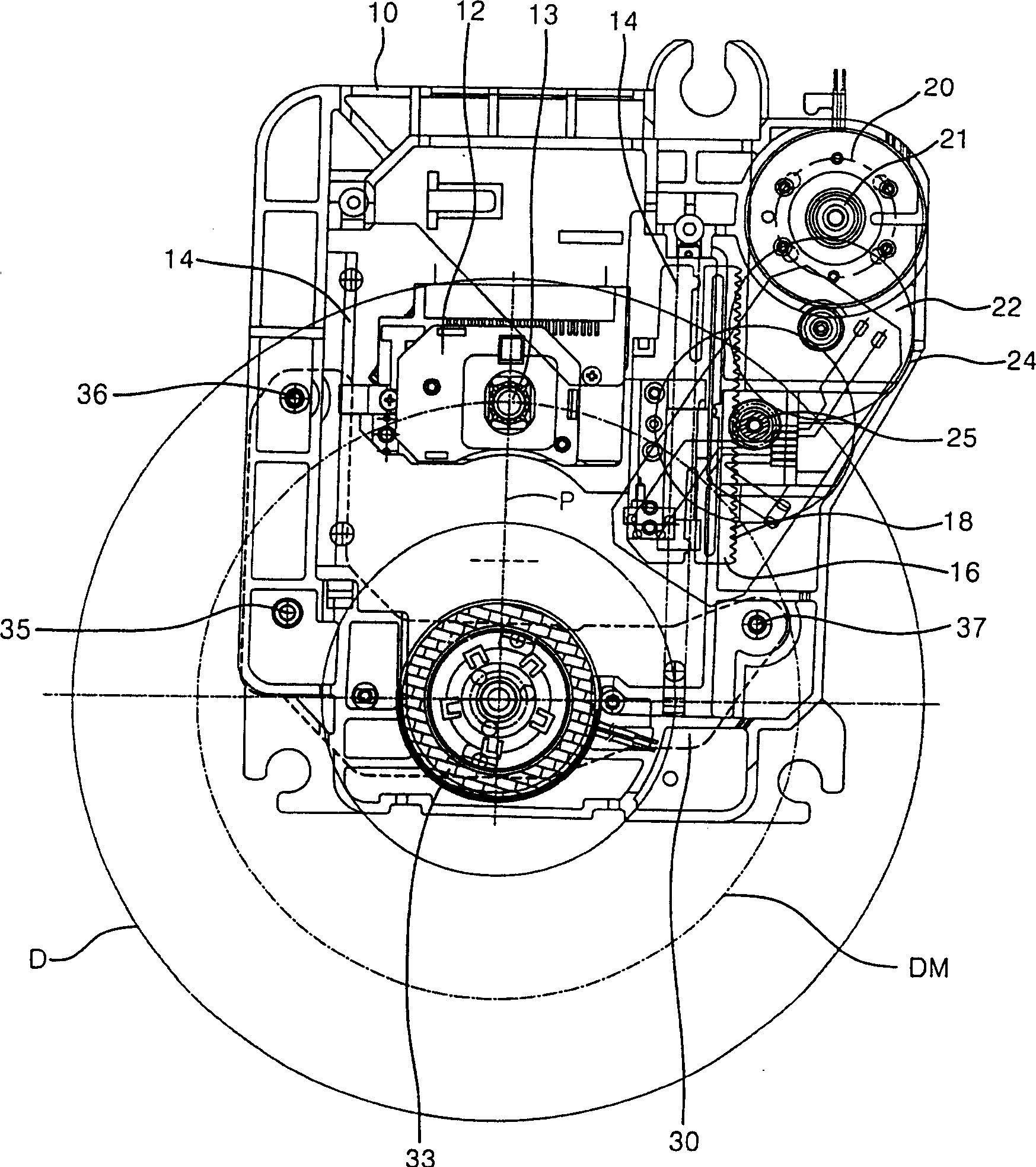

[0047] image 3 It is a plan view of the partial composition of the optical disk drive manufactured by using the technology of the tilt adjustment device of the present invention; Figure 4 It is a plan view of the motor base of the embodiment of the present invention; Figure 5 It is a configuration side view of an embodiment of the present invention.

[0048] As shown in the drawings, the laser head base 10 is disposed on a substrate (not shown), and a laser head 12 is disposed on the surface thereof. The laser head 12 is provided with a laser head lens 13, through which the laser light can be concentratedly irradiated on the signal recording surface of the optical disc D, the laser head 12 can not only irradiate the laser light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com