Washing machine timer and double drum washing machine using said timer

A washing machine, timer technology, applied in the direction of the washing machine's control device, application, washing device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The timer and the double-tub washing machine in the embodiment of the present invention are based on the prior art according to the national standard GB3665 "Household Electric Washing Machine Timer" or GB / T11707 "Household Electric Washing Machine Timer Motor Timer" and GB4288 "Household Electric Washing Machine" Improved on the basis of timer and double tub washing machine.

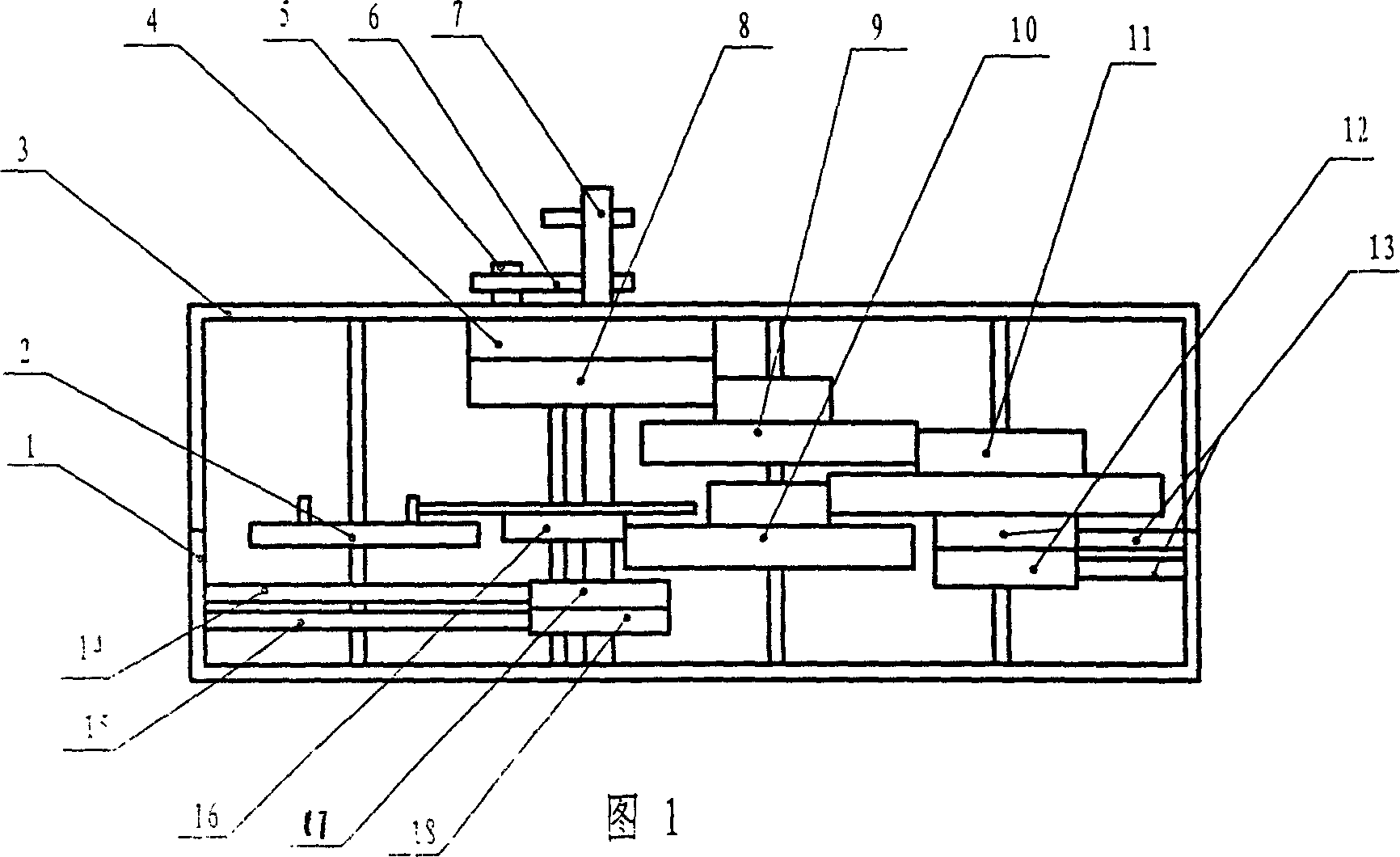

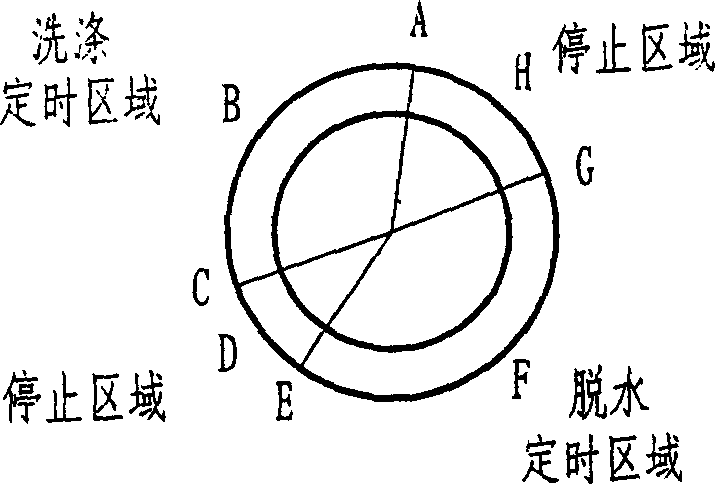

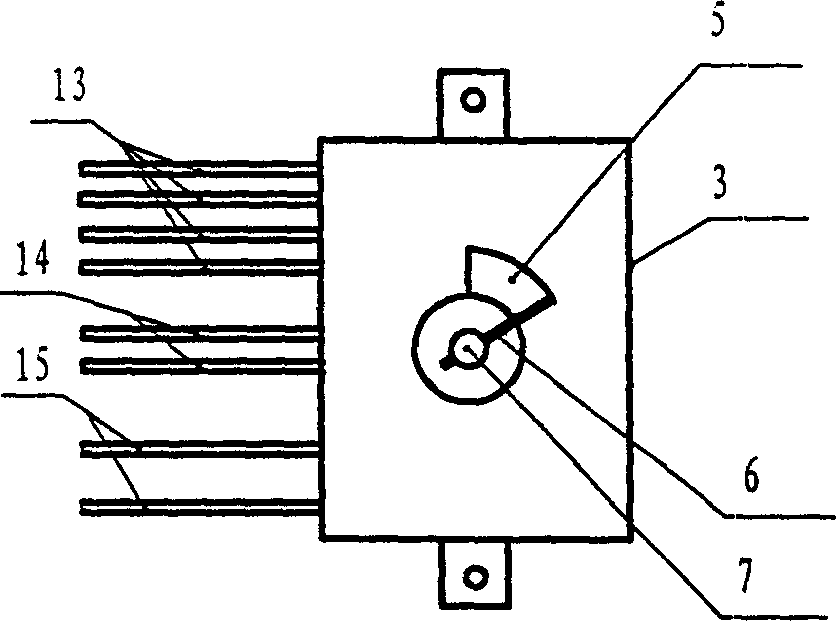

[0025] The first embodiment of the present invention is a mechanical timer, and its internal structure is shown in Fig. 1. The main shaft 7 of the timer is equipped with a mainspring 4, a head wheel group 8, a washing timing cam 17, and a dehydration timing cam 18; the head wheel group 8 meshes with the pinions of the second wheel group 9, the second wheel group 9 and the four wheel group Group 10 is mounted on the same shaft, the large gear of the second wheel group 9 meshes with the small gear of the third wheel group 11, the large gear of the third wheel group 11 meshes with the small gear of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap