Butterfly valve

A butterfly valve and valve body technology, applied in the field of new butterfly valves, can solve the problems of high temperature resistance, high pressure performance and low service life, increase the volume of the valve body and production cost, increase the connection links, etc., and achieve compact structure, simple and novel structure, Reduce the effect of linking links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

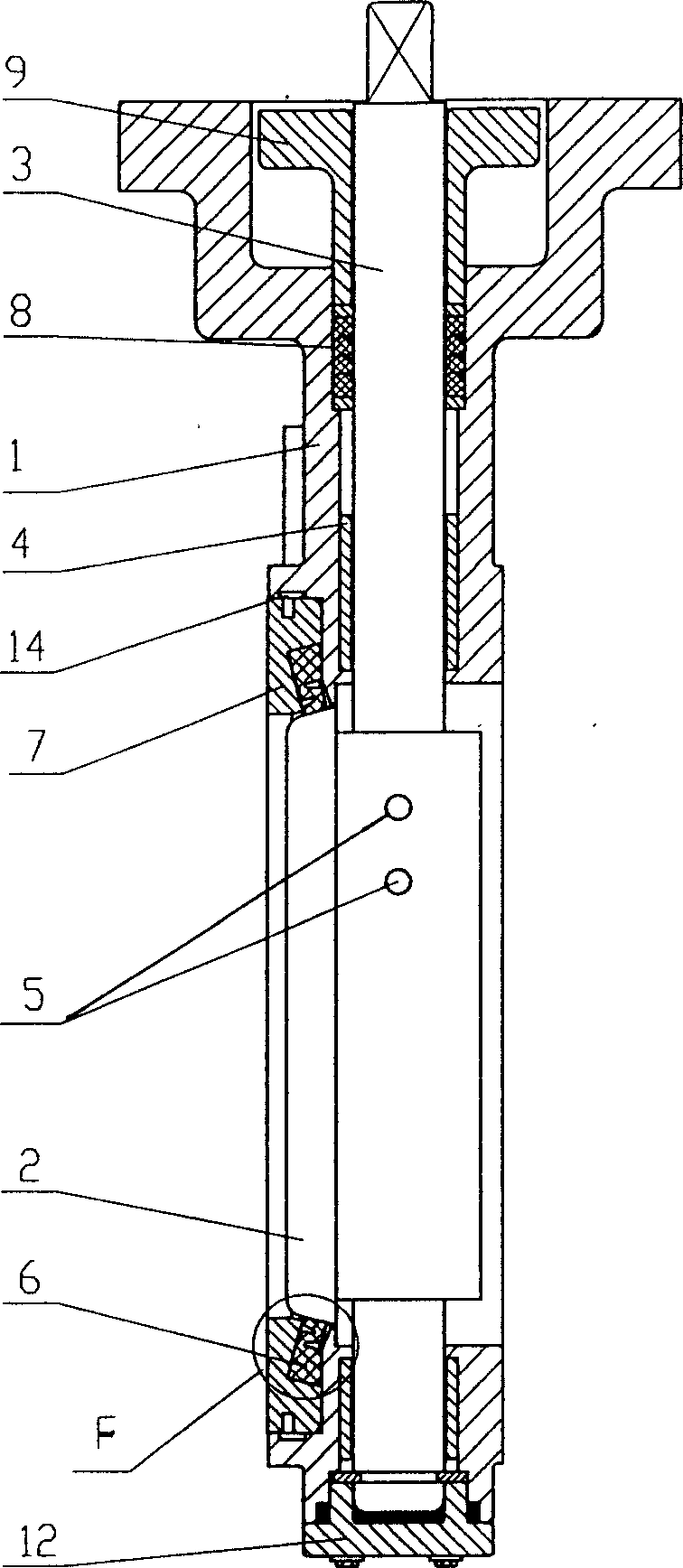

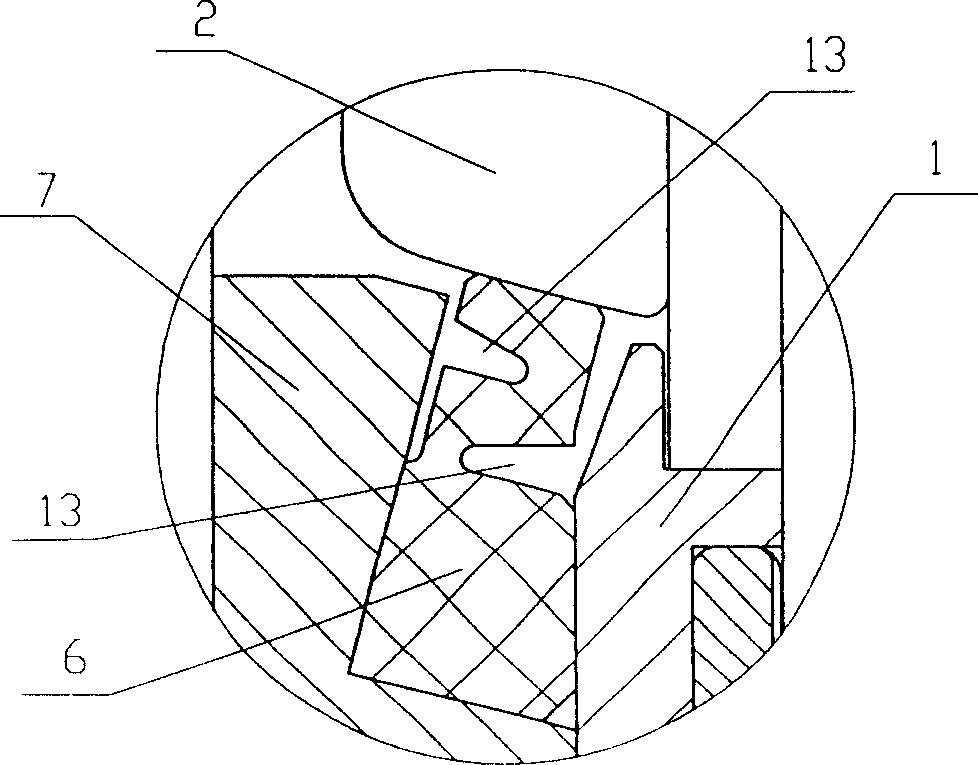

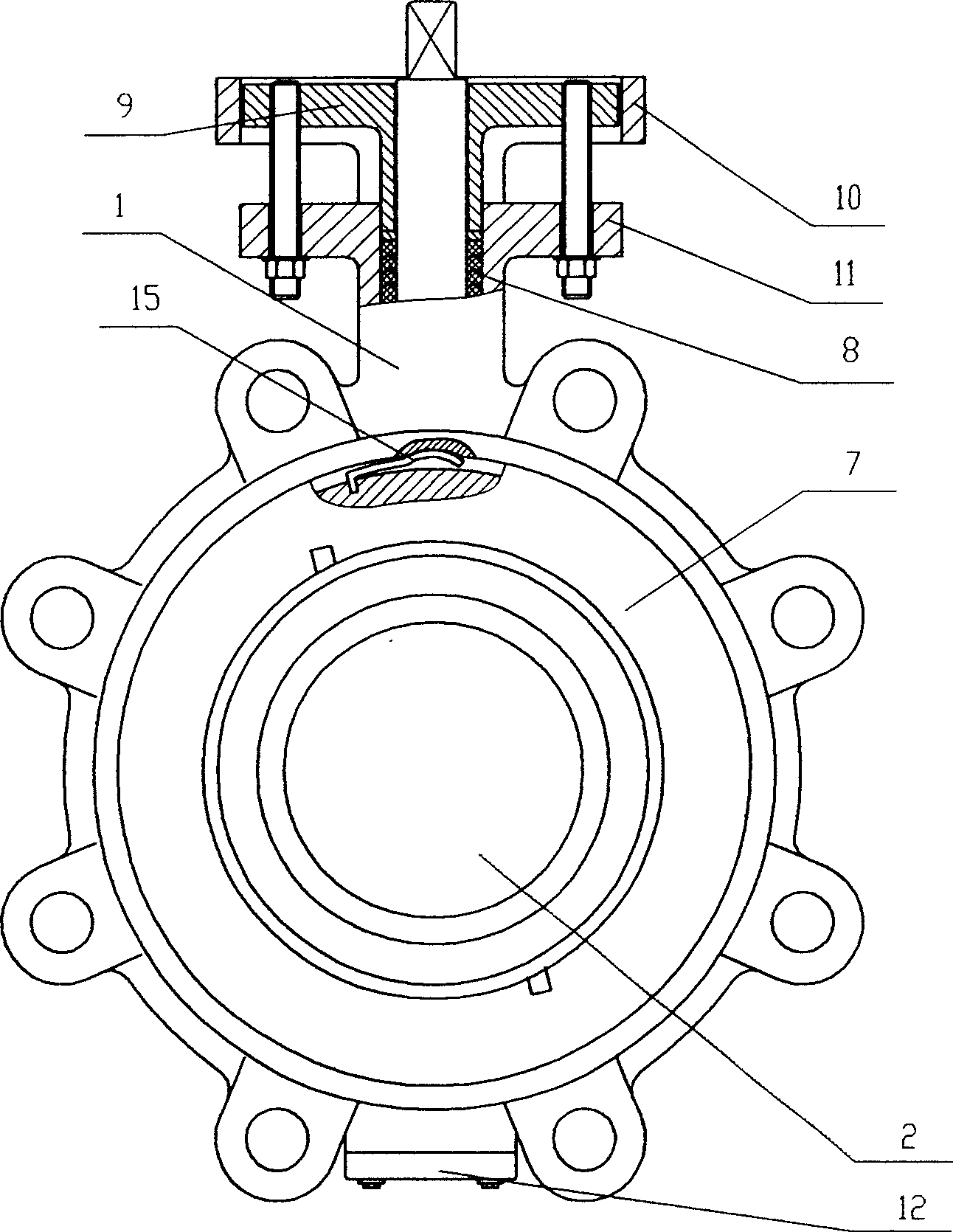

[0017] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

[0018] Such as Figure 1 to Figure 5 As shown, the butterfly valve consists of valve body 1, valve plate 2, rotating shaft 3, shaft sleeve 4, positioning pin 5, sealing ring 6, sealing pressure ring 7, packing 8, packing gland 9, upper flange 10, connecting support 11. The end cover 12 is connected; the valve plate 2 is connected with the rotating shaft 3 through the positioning pin 5 and placed in the cavity of the valve body 1, and the rotating shaft 3 is placed in the sleeve 4 and positioned in the valve body 1. The valve that cooperates with the valve plate 2 A sealing ring 6 and a sealing pressure ring 7 are arranged in the cavity of the body 1, a packing 8 is arranged in the shaft hole of the valve body 1, and a packing gland 9 is arranged on it, and an upper flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com