Ultrasonic probe

一种超声探头、滑轮的技术,应用在超声波/声波/次声波诊断、声波诊断、次声波诊断等方向,能够解决从动滑轮偏移、困难超声图像、线材110长等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

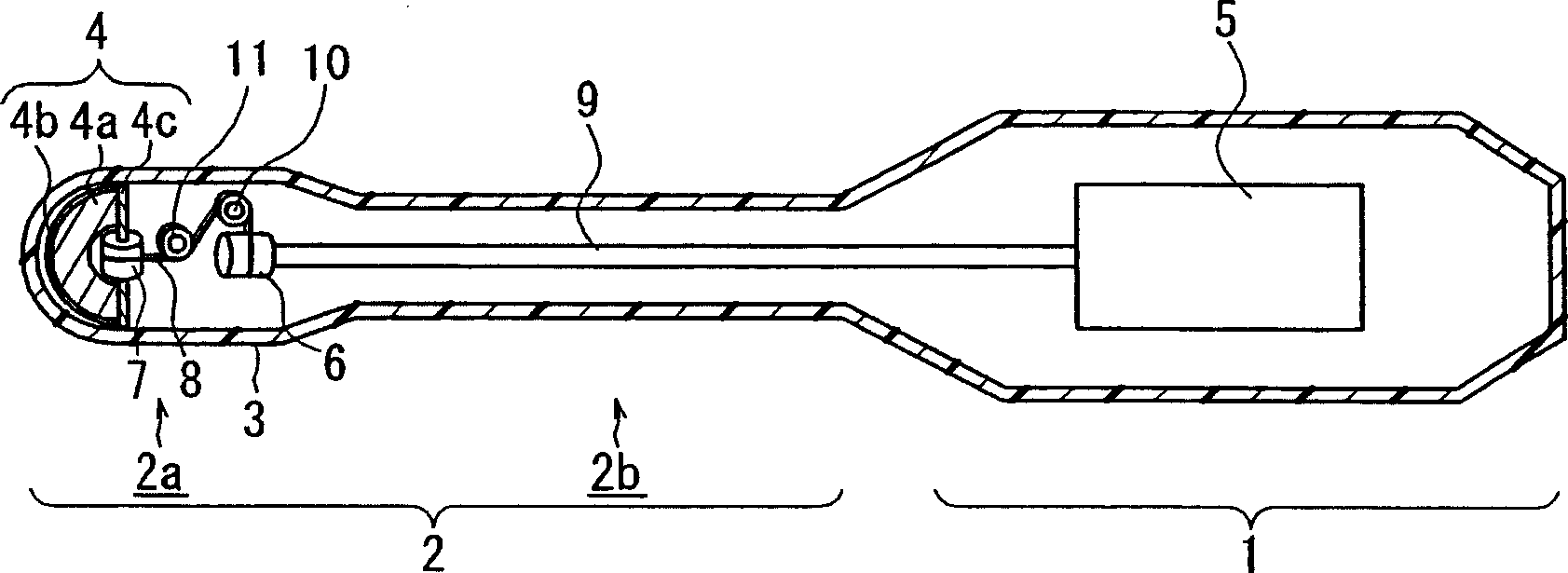

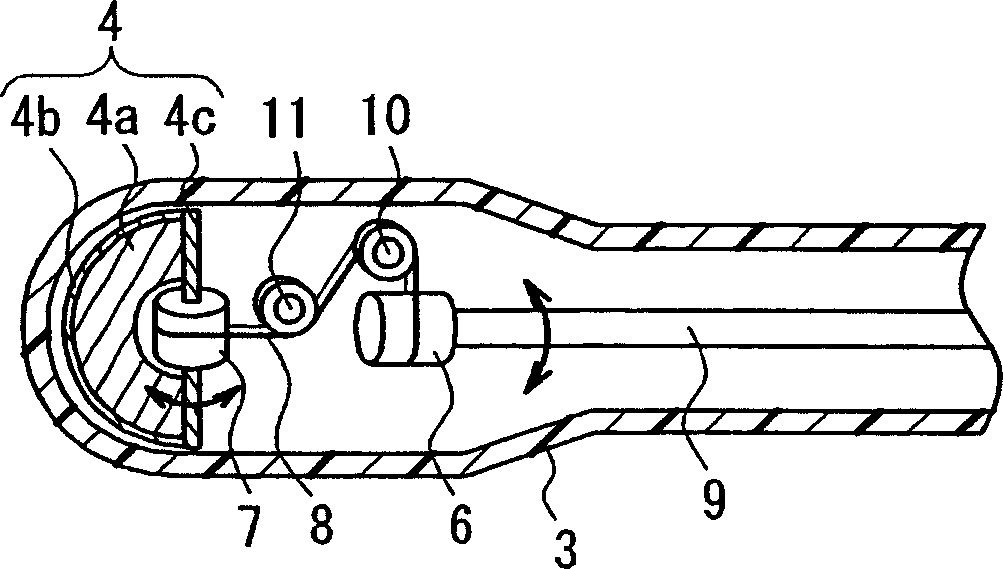

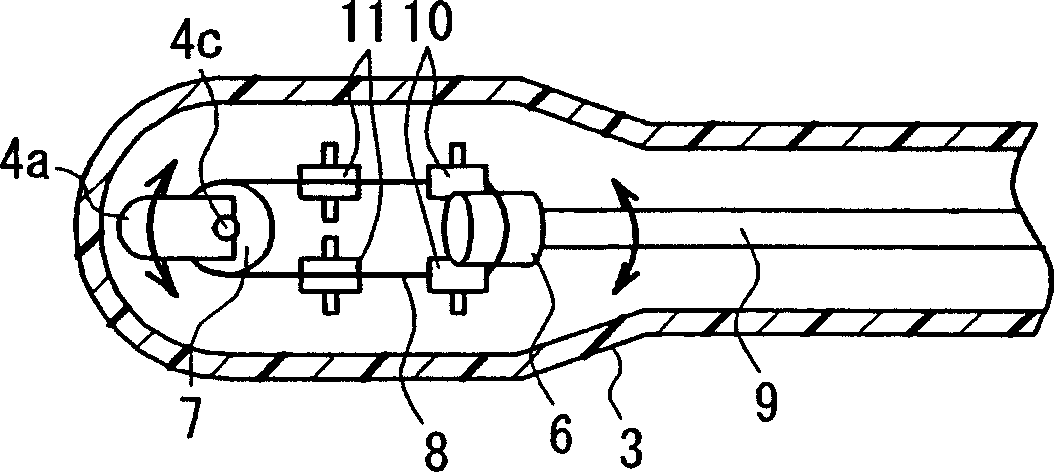

[0017] In the ultrasonic probe of the present invention, the motor in the grip portion generates a driving force, which is transmitted to the first pulley via the shaft, so that the first pulley rotates, and the rotational motion of the first pulley is transmitted to the second pulley via the wire, so that The second pulley rotates, which is why the transducer unit can swing. In this manner, the transducer unit is oscillated by wire driving without using gears, so that unnecessary vibration generated when driving the oscillating mechanism can be reduced.

[0018] In addition, the driving force of the motor is transmitted to the swing mechanism in the insertion portion via the shaft, and is transmitted to the transducer unit in the swing mechanism via the wire. Accordingly, the wires can be made relatively short, which reduces slack in the wires and deflection of the transducer unit.

[0019] In the ultrasonic probe, preferably, the first pulley and the second pulley have the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com