Connecting element for a winding of an electric machine

A technology for wiring units and motors, applied to windings, electrical components, electric components, etc., to achieve the effects of reducing metal material costs, increasing efficiency, and saving waste cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

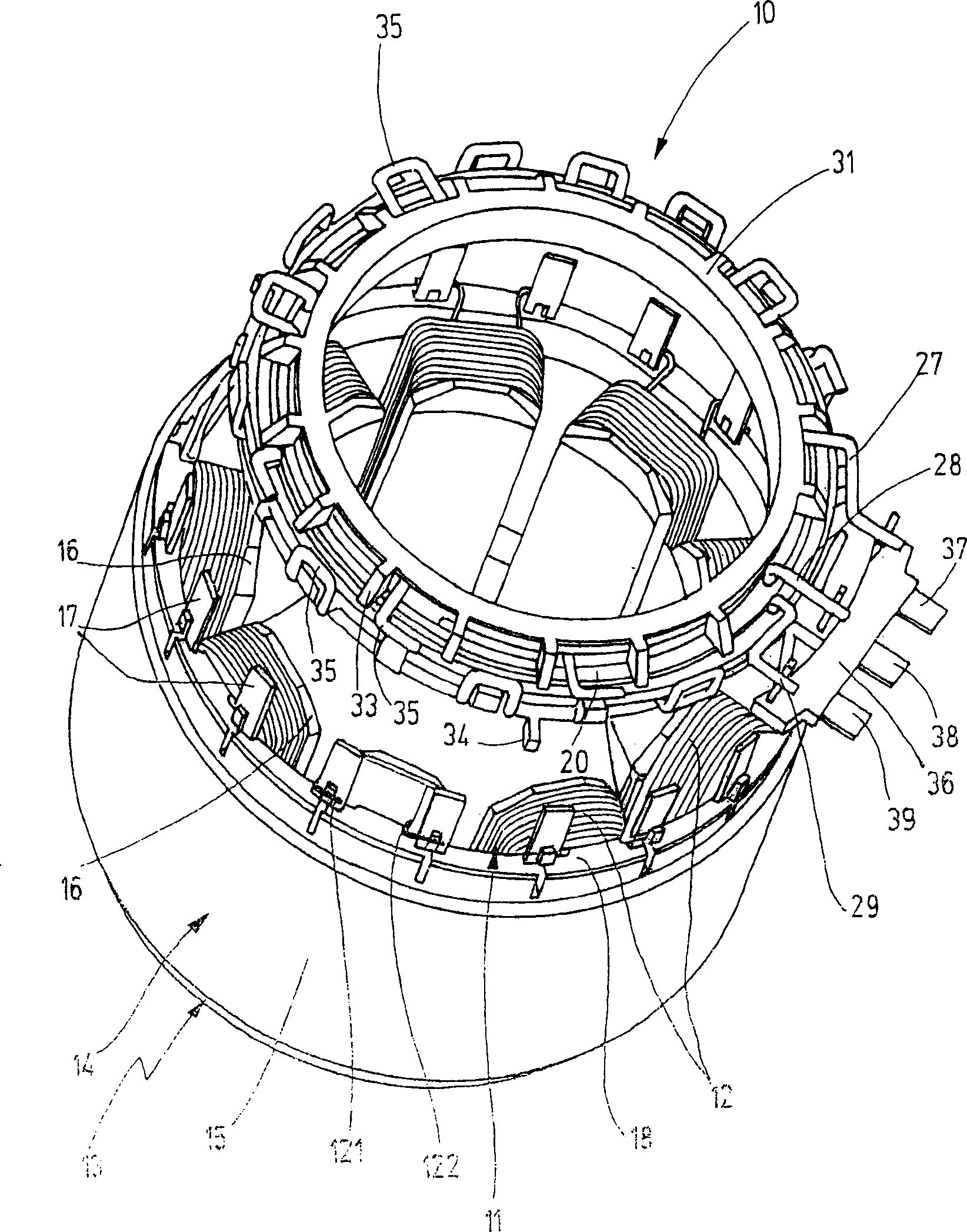

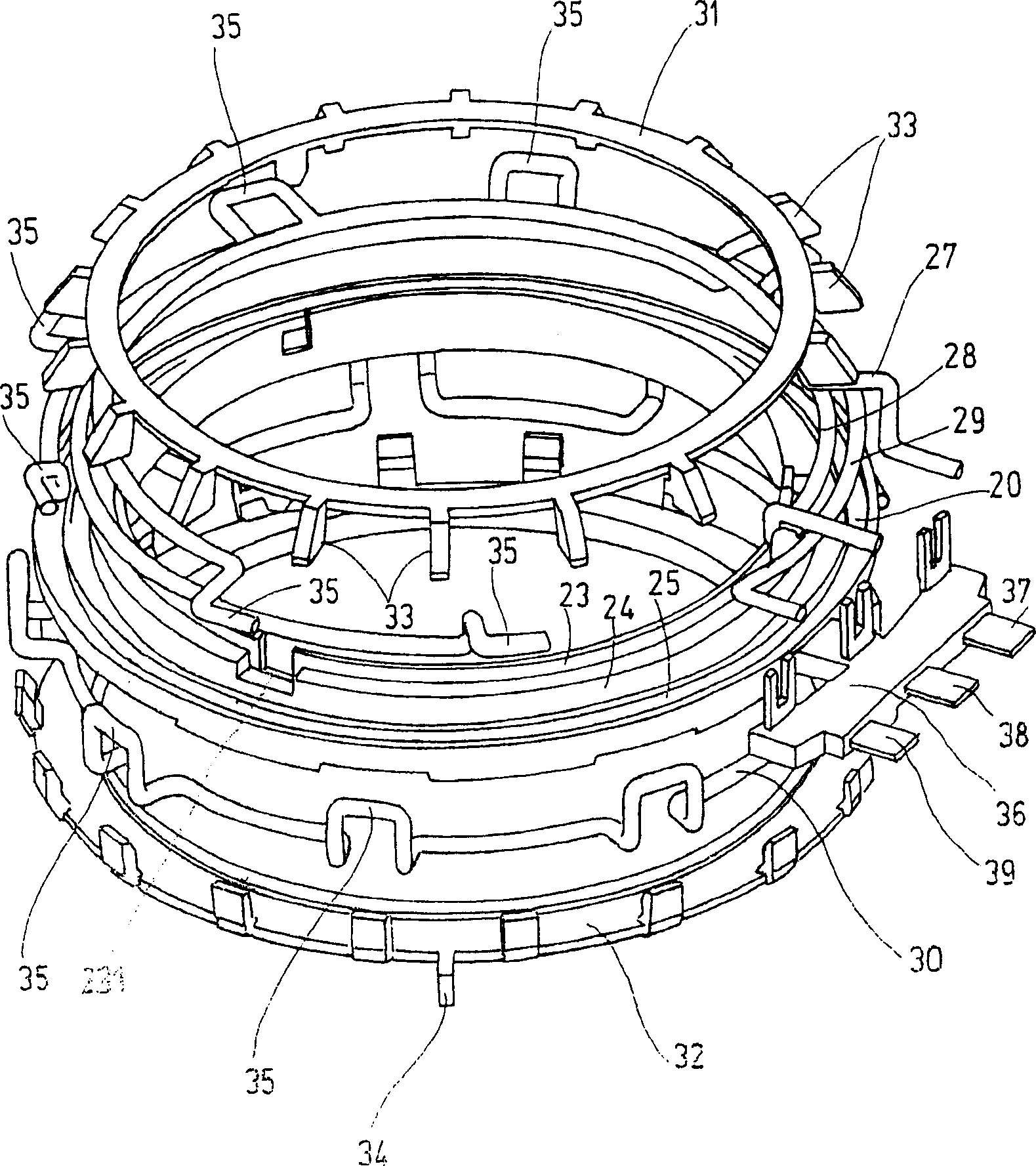

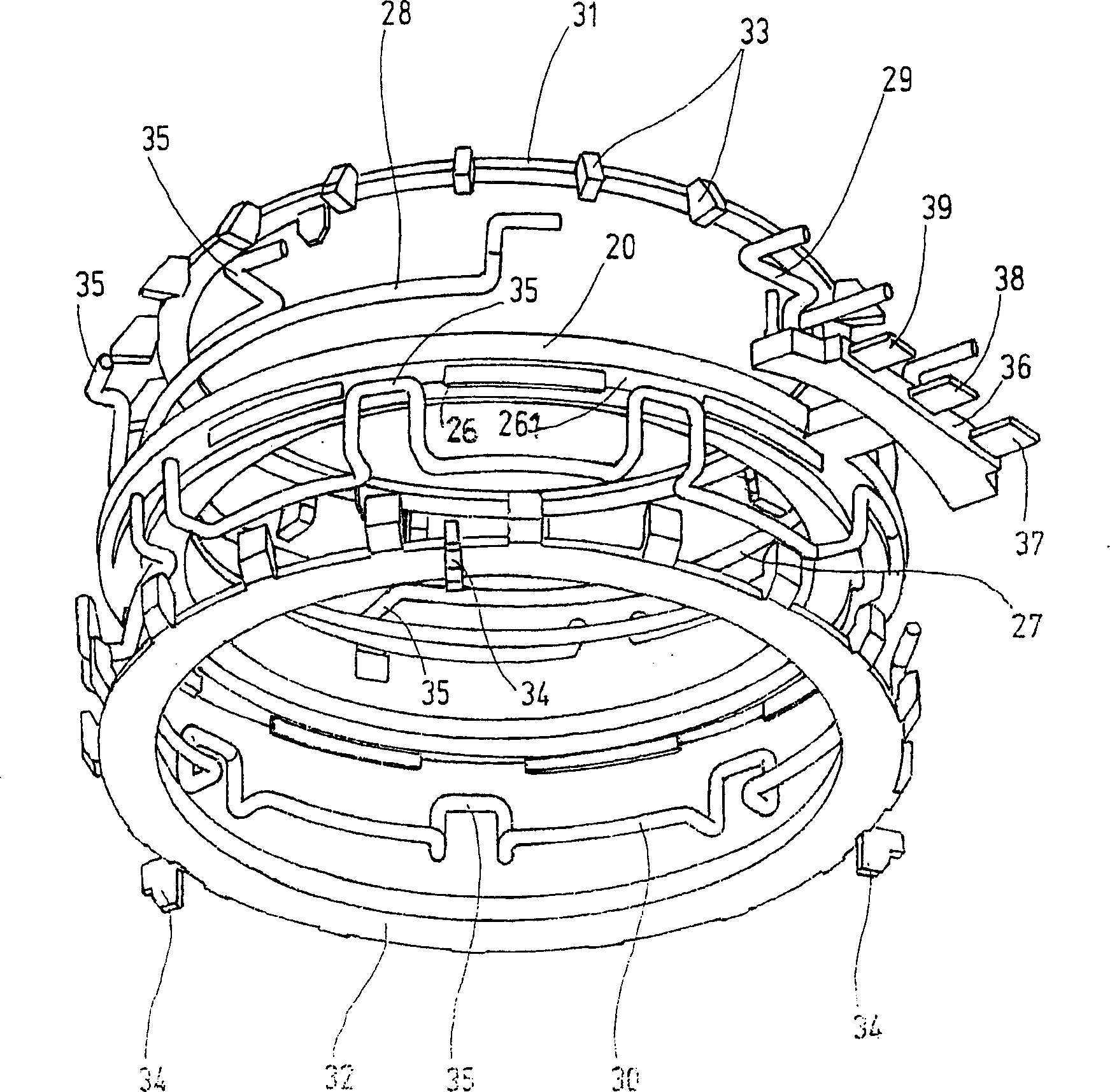

[0011] figure 1 The terminal unit 10 shown in top perspective view is designed for a three-phase winding 11 of nine coils 12 in total of a stator 13 of a brushless small motor, which can be an electronically commutated DC motor or synchronous motor. figure 1 The stator 13 shown in a perspective view has a stator body 14 which comprises, in a known manner, a hollow-cylindrical flux-conducting ring 15 and, in the exemplary embodiment, a total of nine stator teeth 16 projecting radially therefrom, These stator teeth and a rotor (not shown here) delimit the working air gap of the electric motor. An annular coil 12 is wound on each stator tooth 16 , and the coil ends 121 and 122 of each coil 12 are respectively connected to a connecting pin 17 . Viewed from the circumferential direction, the connection locks 17 are arranged equidistantly and protrude from the end face of the magnetic conduction ring 15 , and they are electrically insulated from the magnetic conduction ring 15 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com