Elastic processing method of diving suit cloth

A processing method and elastic technology, which is applied in the field of elastic processing of wetsuit fabrics, can solve problems such as poor fit and lack of comfort, and achieve low modulus, flexible limbs, and the effect of reducing discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

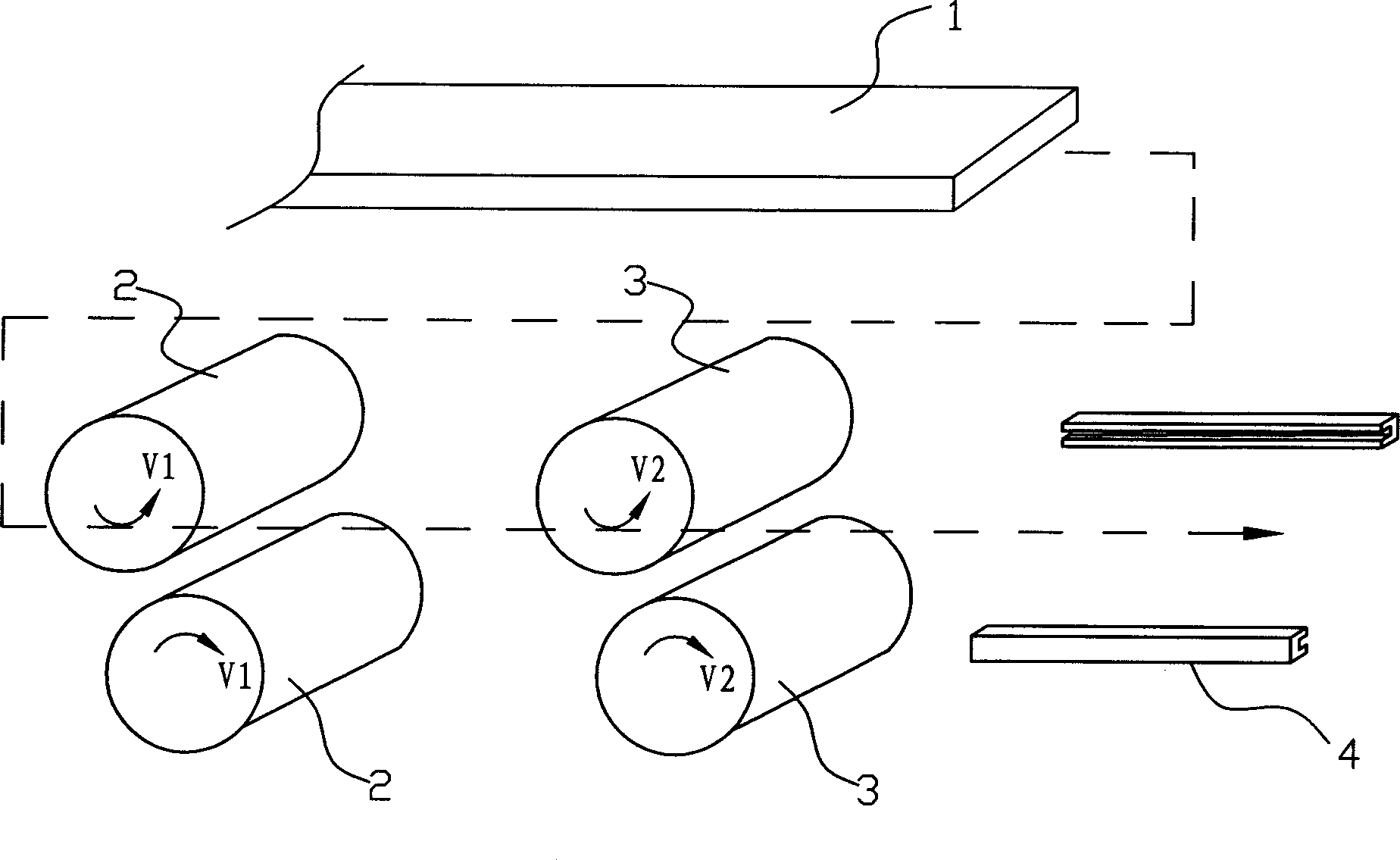

[0013] The elastic processing method of the diving suit cloth according to the present invention mainly includes the longitudinal stretching process of the rubber squeeze roller and the process of transversely stretching the diving cloth after the longitudinal stretching treatment by a pair of automatic sheet pullers.

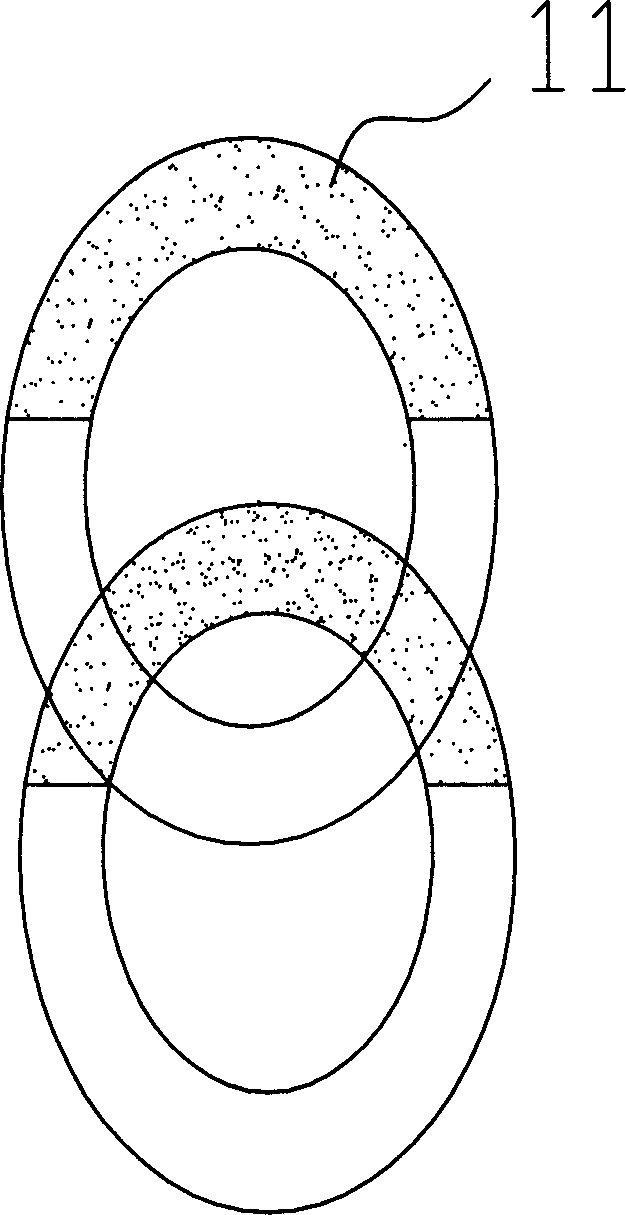

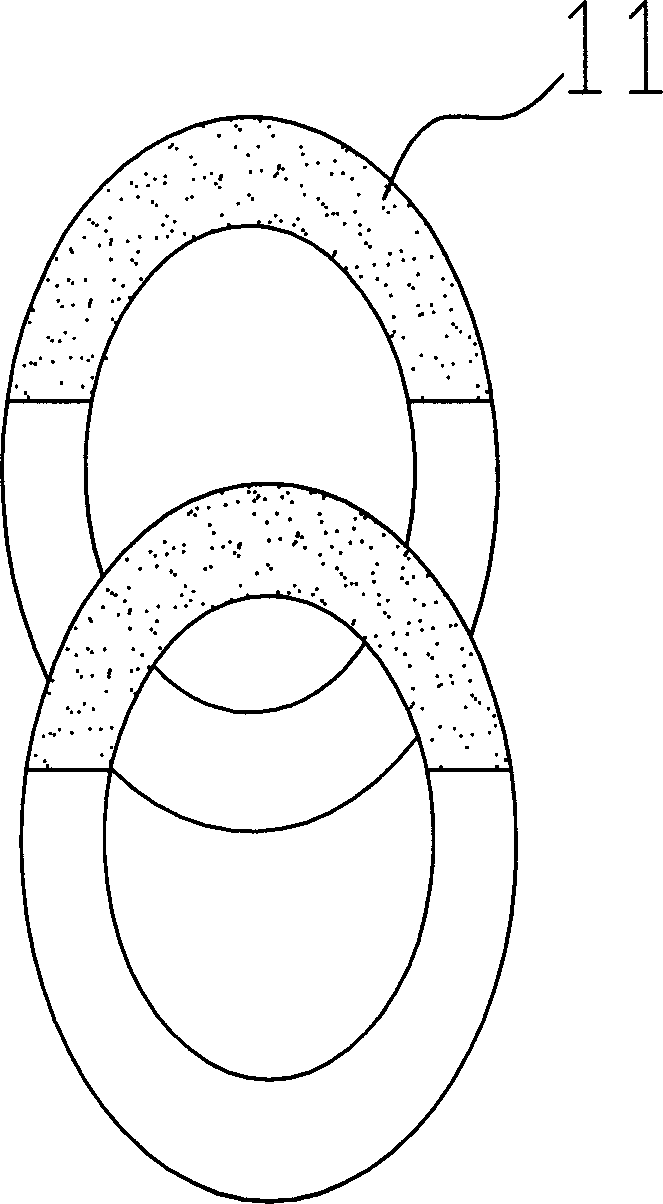

[0014] Such as figure 1 , 2 As shown in , 3, the diving suit cloth piece 1 made of artificial rubber and laminated with knitted high-elastic cloth is processed by a rubber squeeze roller, thereby dispersing and eliminating the fabric loop 11 of the knitted cloth, so that the whole cloth piece 1 increases elasticity .

[0015] Two groups of rubber extrusion rollers 2 and 3 rotate at different speeds to compact the diving suit cloth sheet 1 tightly. The rotational speed of the first group of rubber extrusion rollers 2 is V1, the rotational speed of the second group of rubber extrusion rollers 3 is V2, and V1 is smaller than V2. Because there is a speed differe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap