Gray mask and method for manufacturing gray mask

A gray-tone mask and mask technology, which is applied in the photoengraving process of the pattern surface, the manufacture of semiconductor/solid-state devices, and the original for photomechanical processing, etc. Less than the gray tone mask and other problems, to achieve the effect of good graphics accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Hereinafter, the present invention will be described in detail through embodiments.

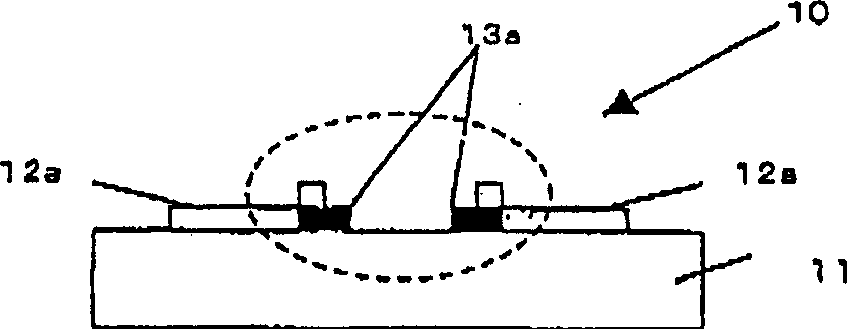

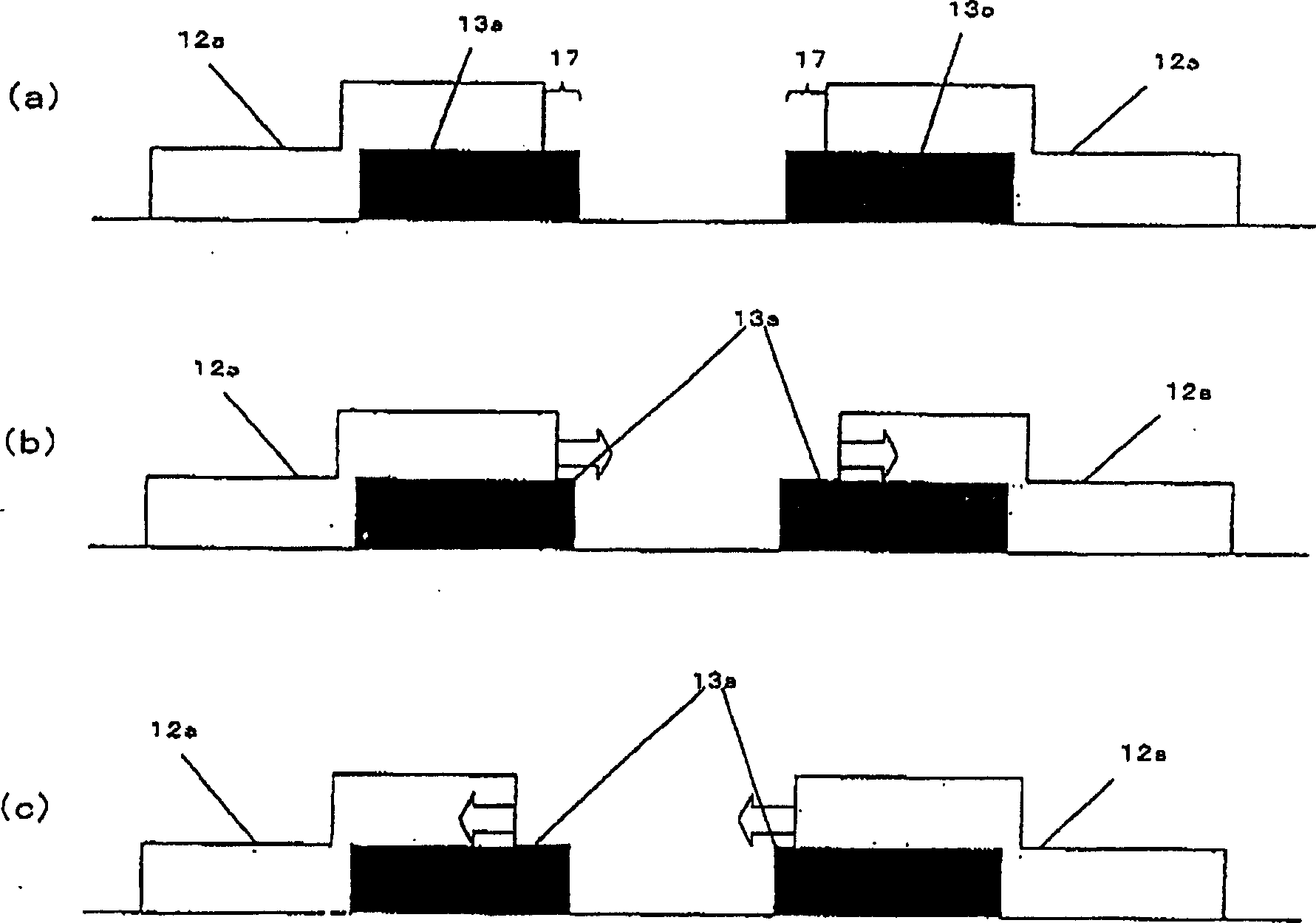

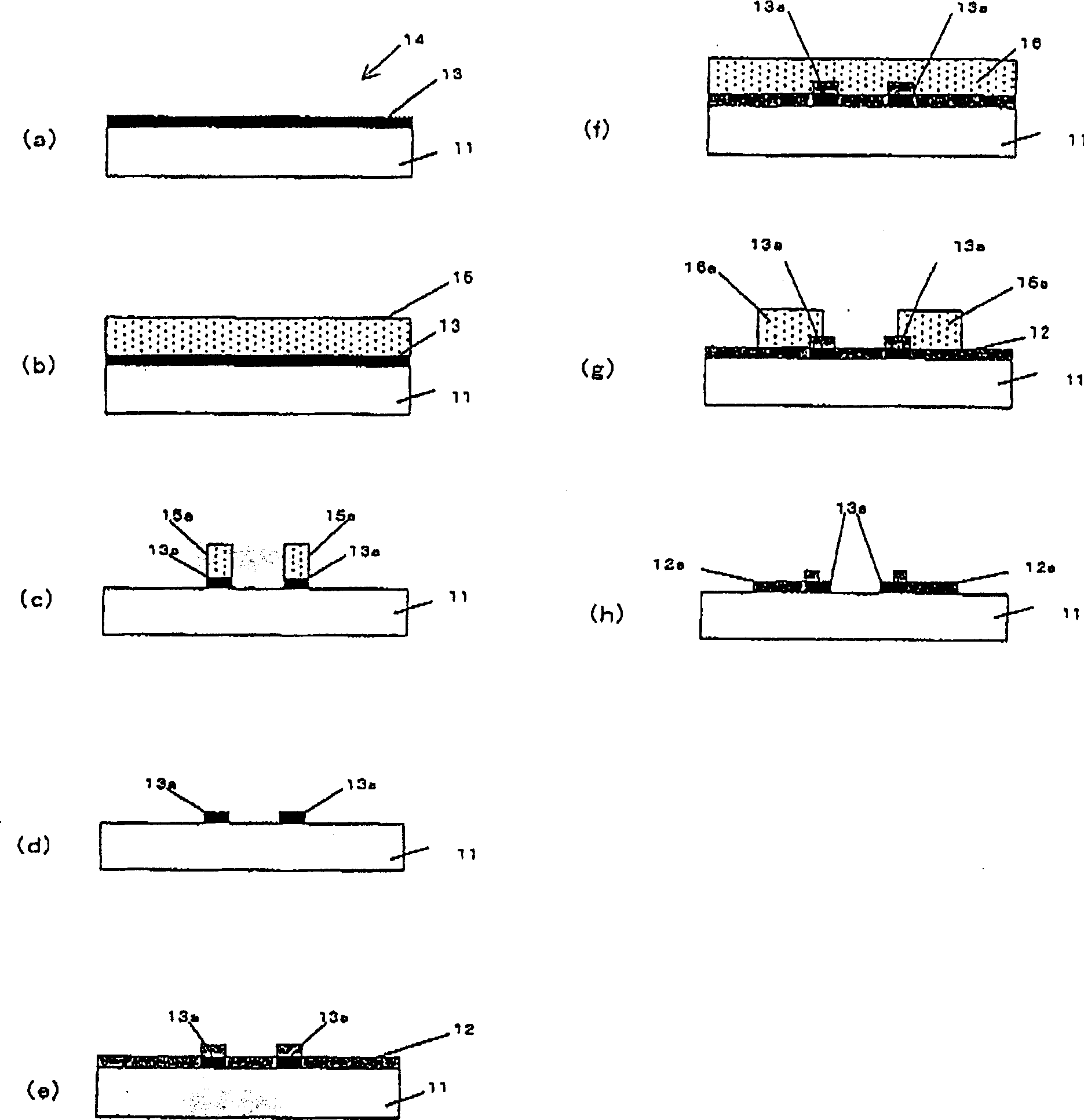

[0073] figure 1 It is a cross-sectional view showing the vicinity of a source electrode and a drain electrode on a TFT substrate of a gray tone mask according to Embodiment 1 of the present invention, figure 2 (a) is figure 1 Enlarged view of the part surrounded by the dashed line in .

[0074] like figure 1 and figure 2 As shown, in this embodiment, on the transparent substrate 11 such as quartz, as the opposing portion of the source electrode and the drain electrode, a light-shielding film pattern 13a is formed in the region adjacent to the channel portion, and the source electrode and the drain electrode are connected to the channel portion. In the adjacent part of the track part, except for the margin region 17 on the electrode side, the region on the light-shielding film and the source electrode and the drain electrode part are formed with a semi-transparent film pattern ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com