Etching Compensation Method for High Precision Packaging Substrate

A technology of packaging substrate and compensation method, which is applied in the direction of lithography/pattern, pattern and lithography, printed circuit, etc., can solve the problems of poor line width accuracy/spacing ability, poor line width tolerance control ability, and improper definition of isolated lines and other issues, to achieve the effect of good line width quality, strong graphic adhesion, and good graphic accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

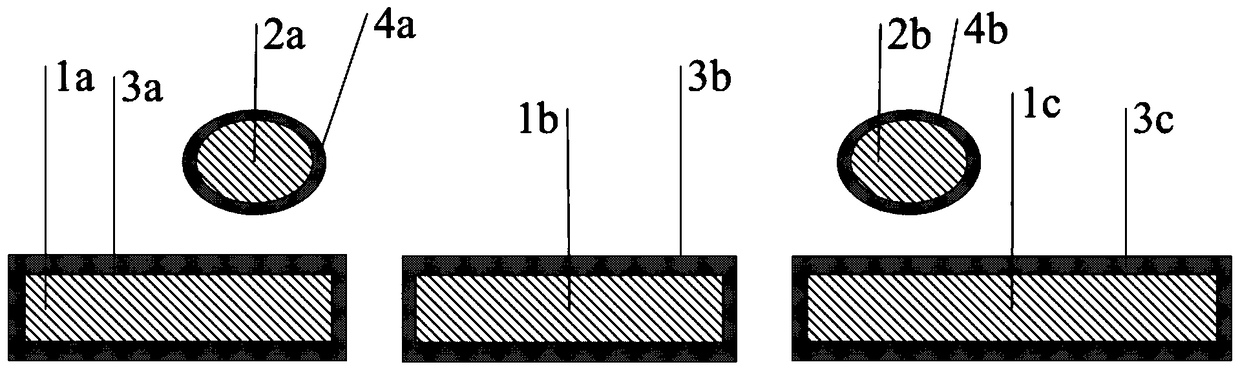

[0026] Such as Figure 1~6 Shown, the steps of the present invention are as follows:

[0027] The first step: graph classification.

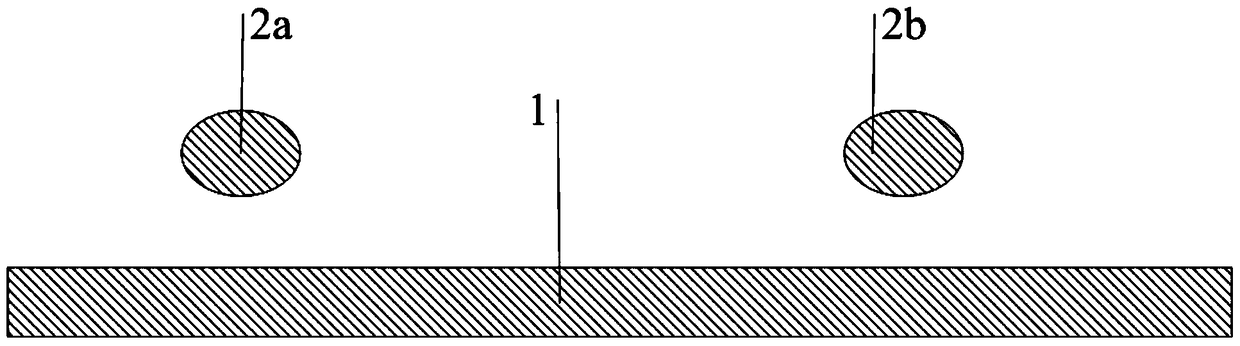

[0028] According to the layout design of the substrate, all design graphic elements are classified, and the graphic types include wires, pads, vias, heat dissipation copper surfaces, etc. Such as figure 1 As shown, the graphic elements are divided into wire 1, pad 2a, 2b.

[0029] Step 2: Break the wire into multiple segments.

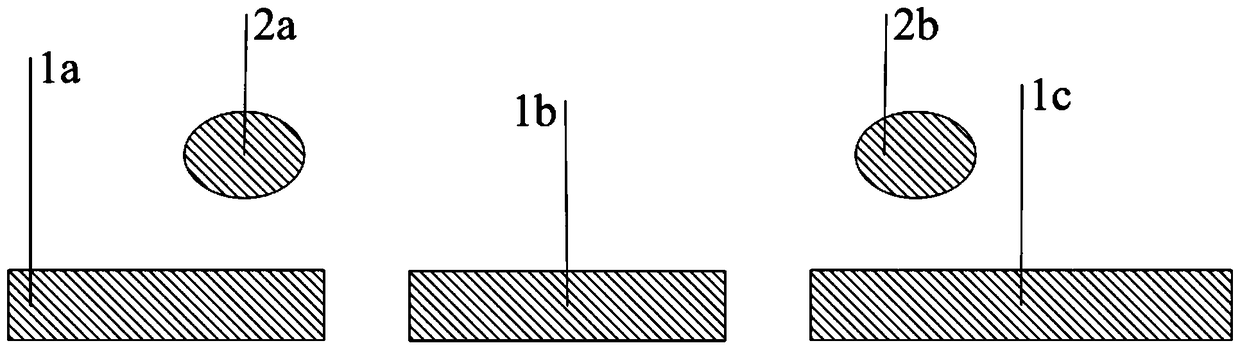

[0030] According to the design logic of adjacent graphics, break all wires into multiple segments, that is, one wire can be broken into 3 segments, 4 segments, etc., such as figure 2 As shown, the wire 1 is broken into three segments, respectively 1a, 1b, and 1c. Considering the adjacent graphics, one line will be broken into multiple line segments. At this time, it should be adjusted according to the design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com