Mask blank, phase shift mask, method for manufacturing mask blank, and method for manufacturing phase shift mask

A phase-shift mask and mask blank technology are applied in the fields of mask blank, phase-shift mask, mask blank manufacturing method and phase-shift mask manufacturing method, and can solve the optical characteristics of phase-shift mask of quartz substrate Changes and other issues to achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

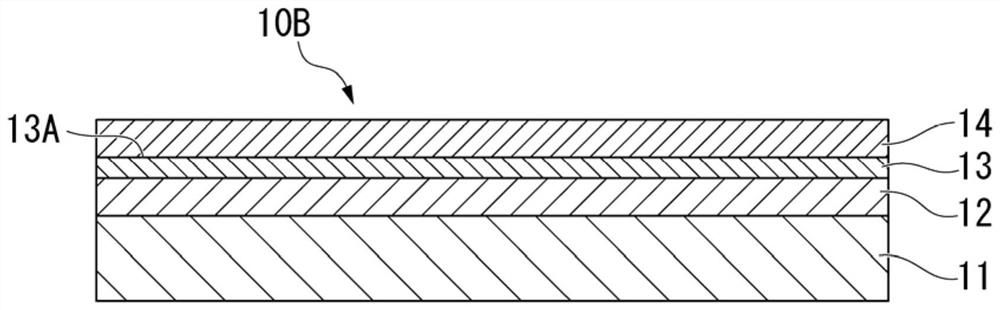

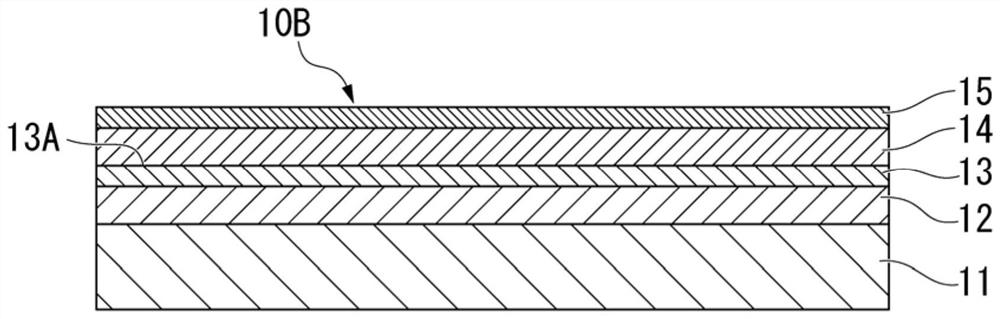

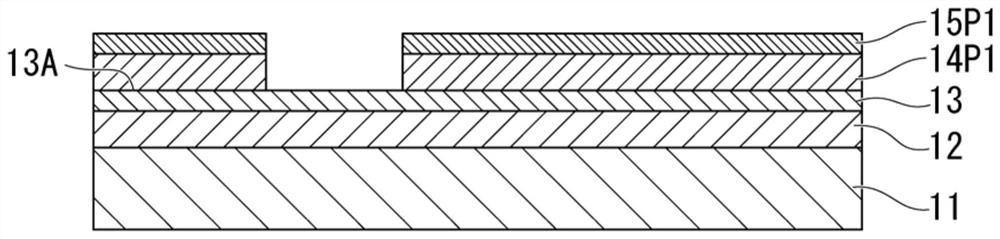

[0254] Next, examples according to the present invention will be described.

[0255] In addition, a confirmation test will be described as a specific example of the etching stopper layer 13 in the present invention.

[0256]

[0257] As Example 1, a molybdenum silicide compound film was formed as an etching stopper on a glass substrate using a sputtering method or the like. The molybdenum silicide compound film formed here is a film containing molybdenum, silicon, oxygen, nitrogen, carbon, and the like. The composition of the film was evaluated using Auger electron spectroscopy.

[0258] show the result in Figure 13 .

[0259] like Figure 13 As shown, it can be confirmed that a peak region with a high nitrogen concentration is formed on the left side of the figure.

[0260] Next, in the sputtering for forming the molybdenum silicide compound film, a target having a molybdenum to silicon ratio of 1:2.3 was used, and the nitrogen partial pressure was changed within 0 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com