High performance silence aluminum extrusion radiating fin array

A heat dissipation fin and aluminum extrusion technology, which is applied in the direction of instruments, electrical digital data processing, digital data processing parts, etc., can solve the problems of difficult choice between noise and heat dissipation, and achieve the effect of low-cost manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

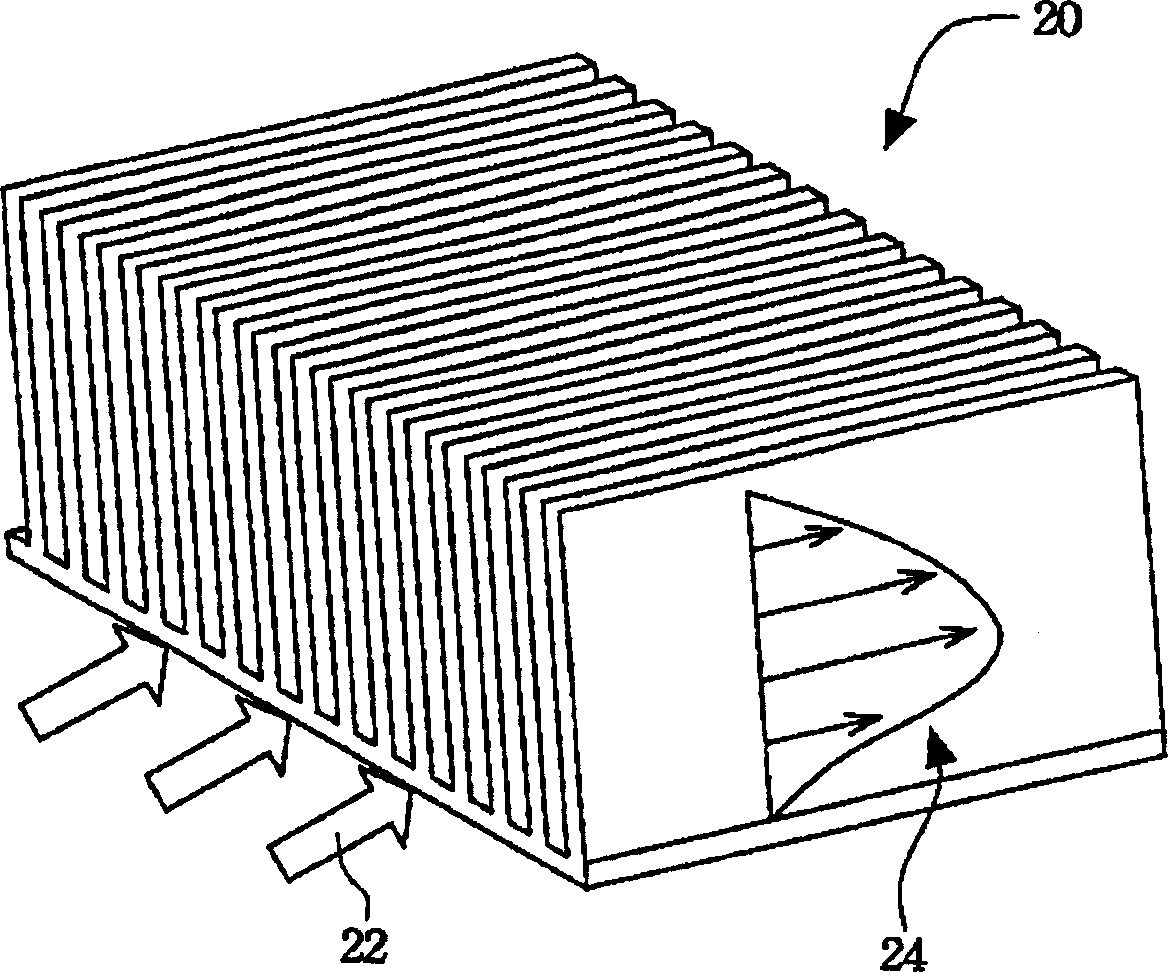

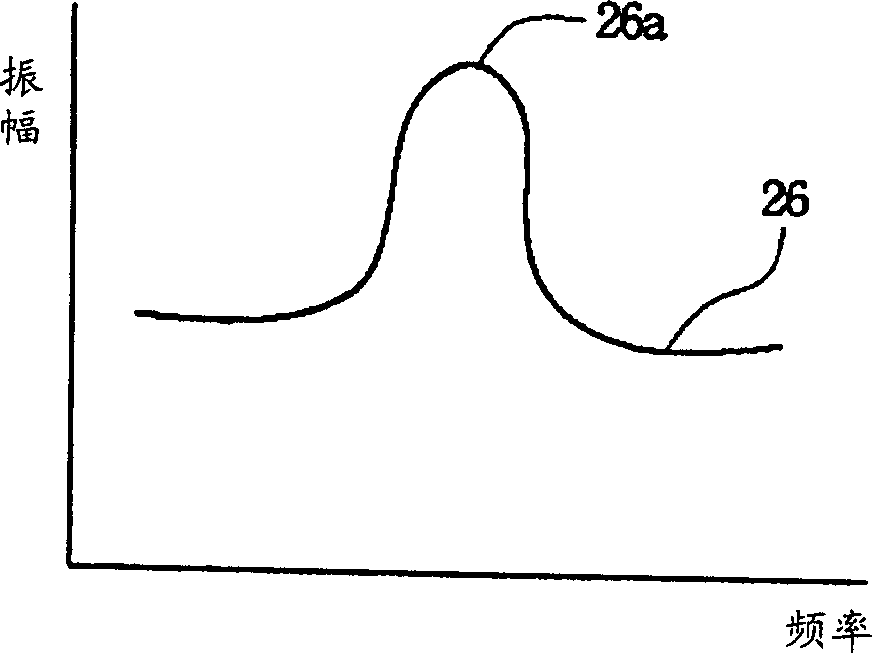

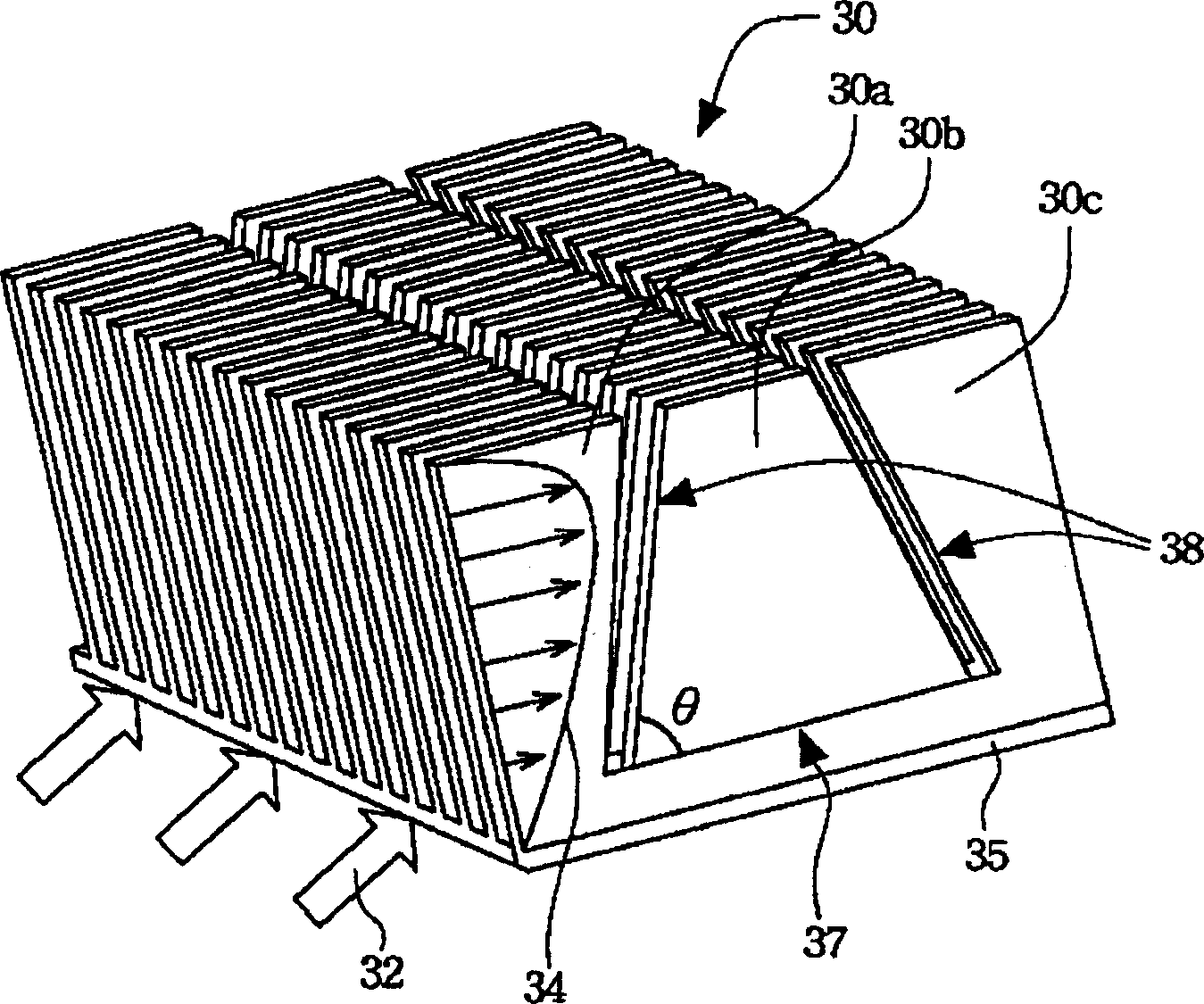

[0013] In order to solve the bottleneck that is difficult to choose between noise and heat dissipation, the present invention proposes a high-efficiency sound-absorbing aluminum extruded fin array, by cutting oblique grooves on each fin in the array, and making the The radiating fins at the front and back of the groove diverge left and right. This structure helps to change the flow velocity distribution, and then makes the noise spectrum curve change accordingly.

[0014] Please refer to Figure 2A , which shows a schematic diagram of an aluminum extruded heat dissipation fin array according to a preferred embodiment of the present invention. Different from the existing aluminum extruded heat dissipation fin array, the aluminum extruded heat dissipation fin array 30 of this preferred embodiment cuts a plurality of oblique grooves 38 on each heat dissipation fin, and the oblique grooves 38 The extension direction is preferably an inverted V shape, so that no matter the flow f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com