Fixed bed oxidation desulfur reaction method

A technology of oxidative desulfurization and fixed bed, which is applied in petroleum processing, petrochemical industry and coal processing field, can solve the problems of high price and achieve the effect of improving the atmospheric environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

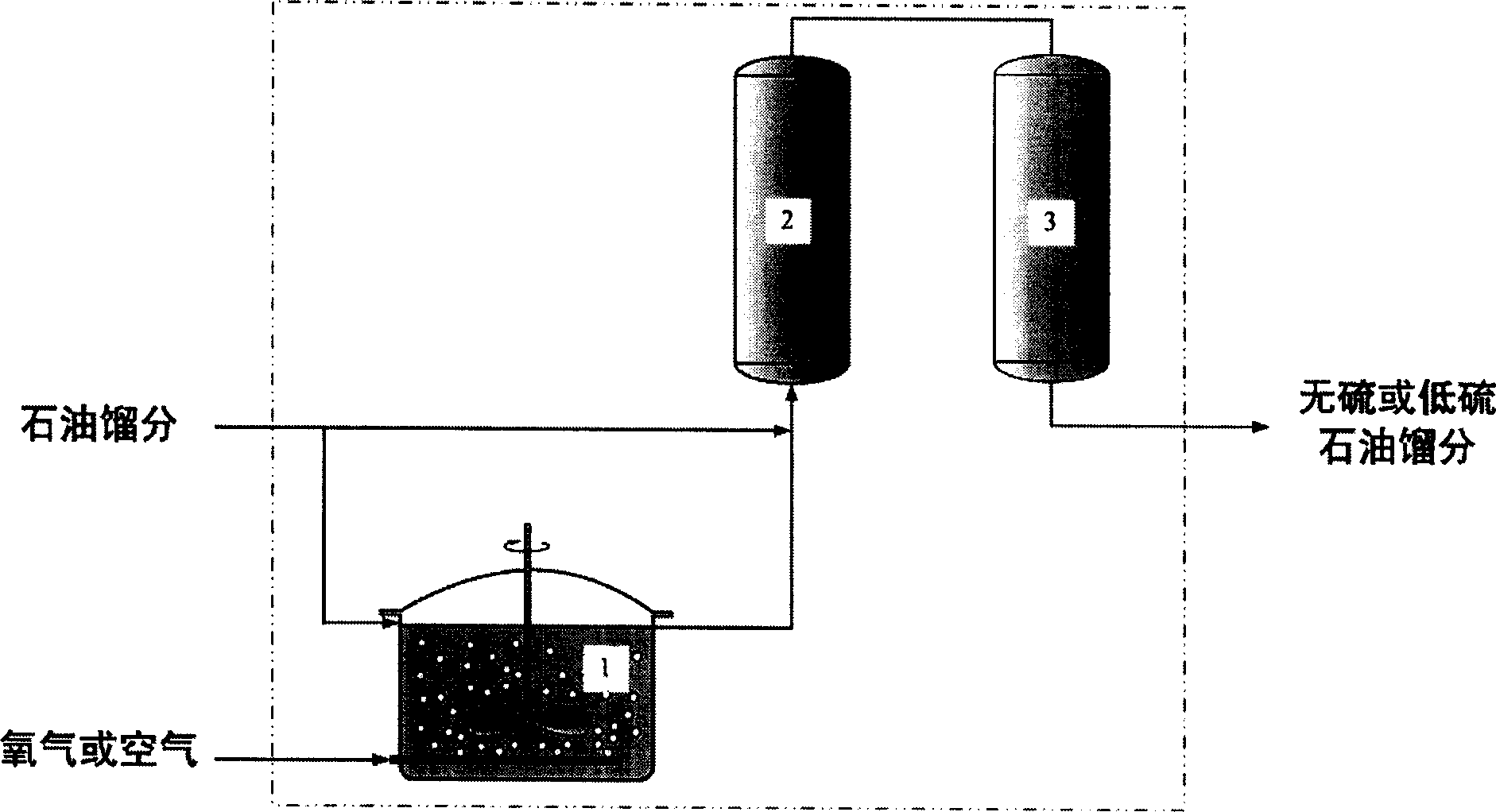

Image

Examples

Embodiment

[0017] Preparation of Organic Peroxides by Air Oxidation

[0018] The raw material is a hydrotreated diesel oil to be oxidized and desulfurized, and its sulfur content is 810 μg / g. Measure 300 milliliters of diesel oil into a three-necked flask, and add 1 milliliter of cumene hydroperoxide as an initiator. The three-necked flask was placed in an oil bath, connected with a condenser, a thermometer and a bubbling device, then heated up and fed with air at a flow rate of 50 ml / min, and started timing when reaching the reaction temperature, and stopped the reaction after 20 hours of reaction. The total peroxide concentration was determined by indirect iodometric method, and its molar concentration was 5.8mol / L.

[0019] Oxidation of sulfur compounds in diesel

[0020] The prepared diesel oil containing organic peroxide and the diesel oil to be oxidized are mixed at a volume ratio of 1:2 to prepare oxidation reaction raw materials. The silica-supported Mo-P oxide catalyst is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com