Structure for preventing lead wire rotating of drum laundry machine

A technology of a drum washing machine and a lead holder, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of inconvenient wire bundling operation, the wire coming out, the lead holder cannot be vertical, etc., and the effect of improving the efficiency of wiring work is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

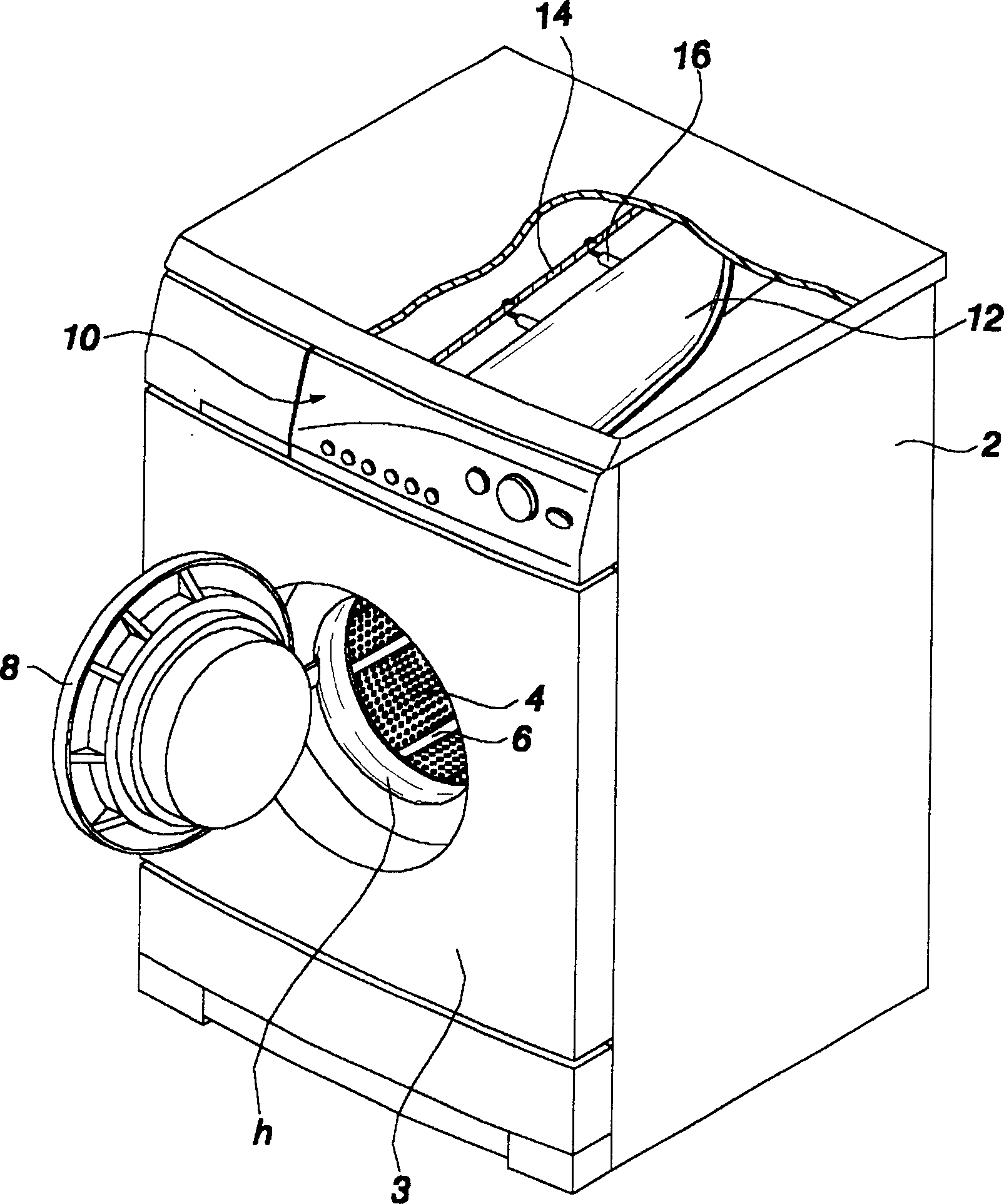

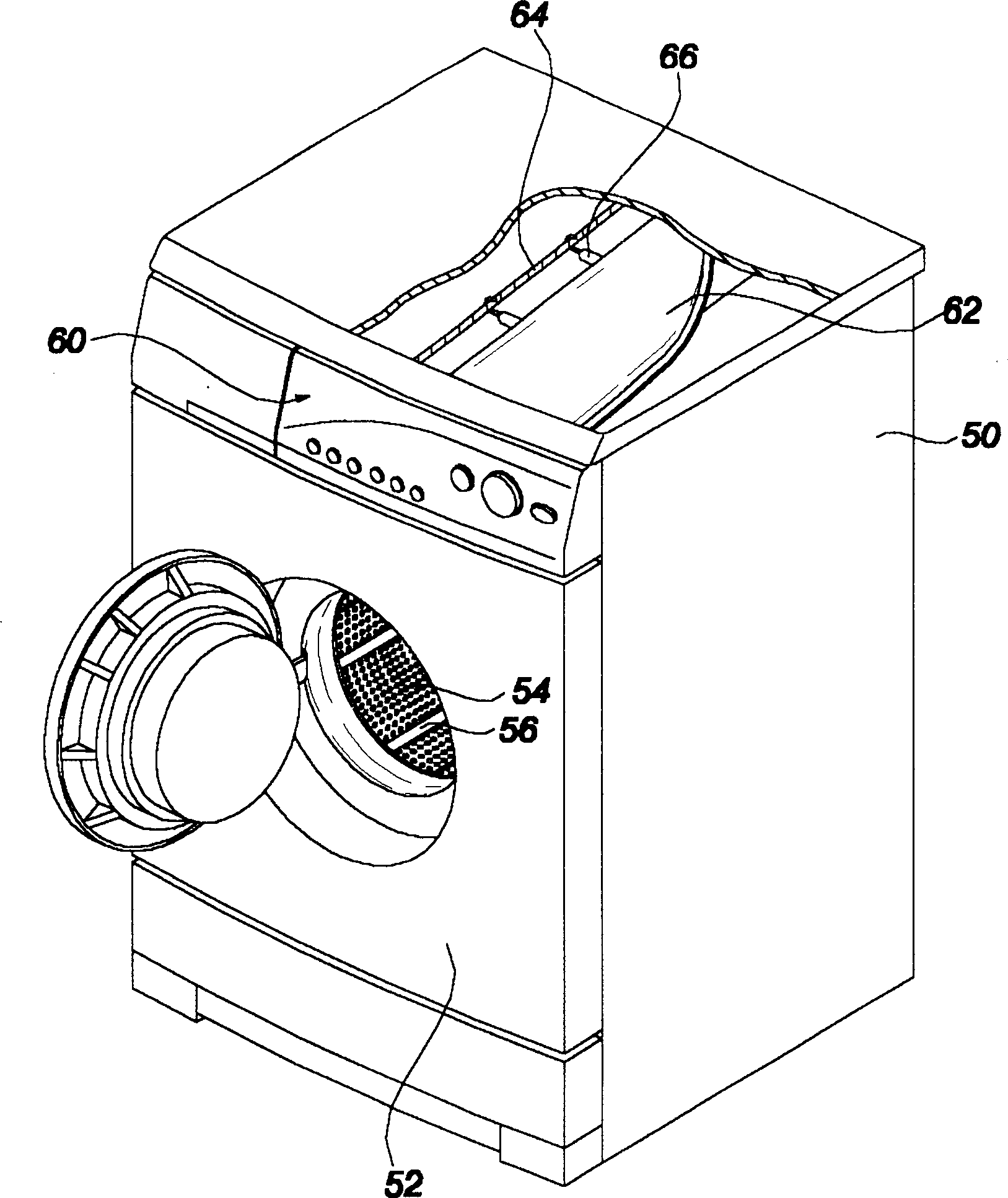

[0028] image 3 It is an oblique sectional view of an example of the front-loading washing machine combined with drying of the present invention, Figure 4 It is an exploded oblique view of the drying duct of the drum washing machine combined with drying according to the embodiment of the present invention, Figure 5 It is an enlarged oblique view of the rotation prevention structure of the drum washing machine combined with drying according to the embodiment of the present invention, Image 6 It is an oblique view of the connection structure between the lead base and the drying conduit of the drum washing machine that also functions as a dryer in an embodiment of the present invention.

[0029] Such as image 3 As shown, the dual-purpose drying drum washing machine according to the embodiment of the present invention includes an outer tub (not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com