Duplex shock absorption device of laundry machine

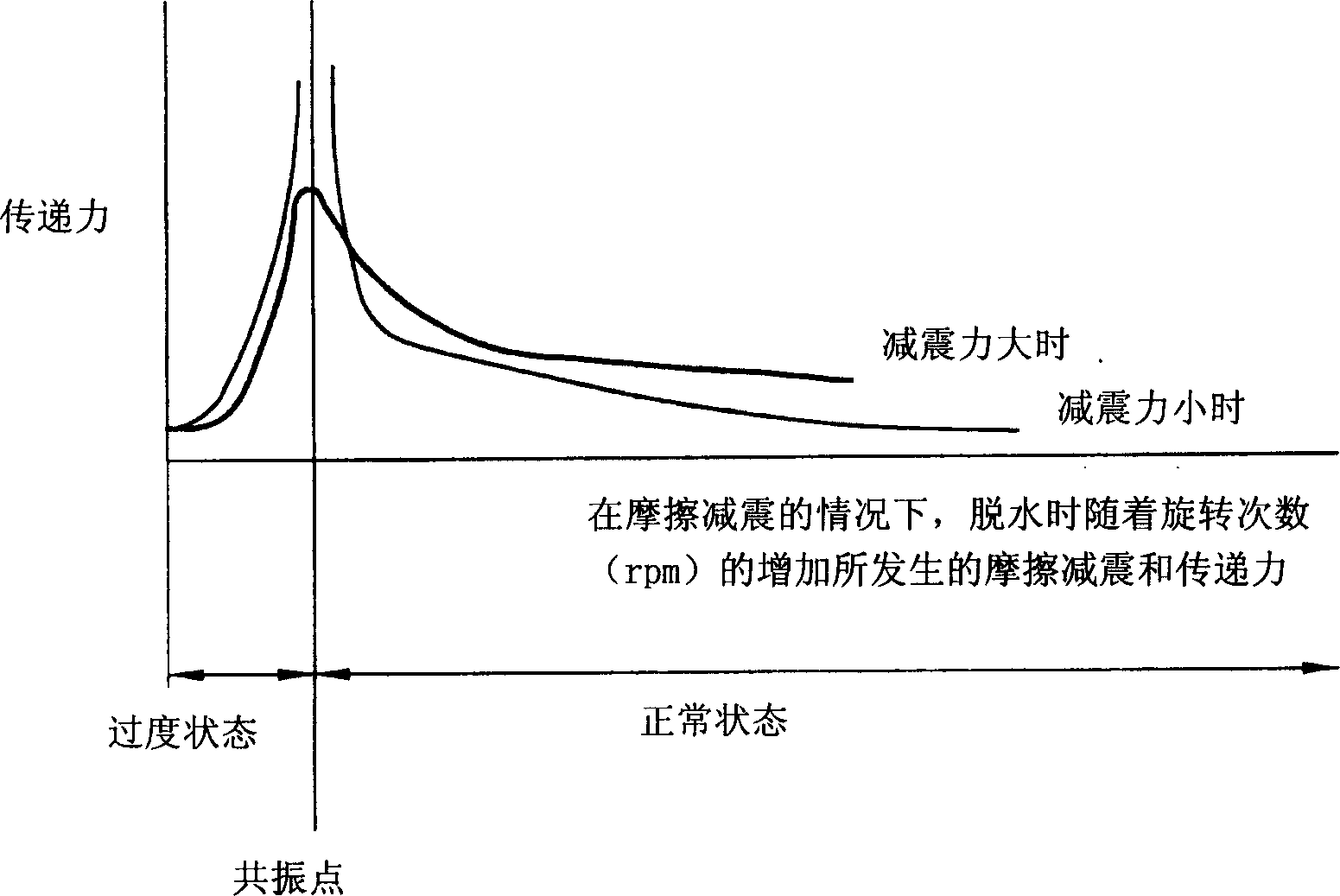

A shock absorber and washing machine technology, which is applied to washing devices, other washing machines, solid shock absorbers, etc., can solve problems such as difficult vibration control, and achieve the effect of small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The double shock absorption device of the washing machine of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0035] In addition, in the following description, among the main components of the present invention, the same parts as those in the prior art are given the same numbers.

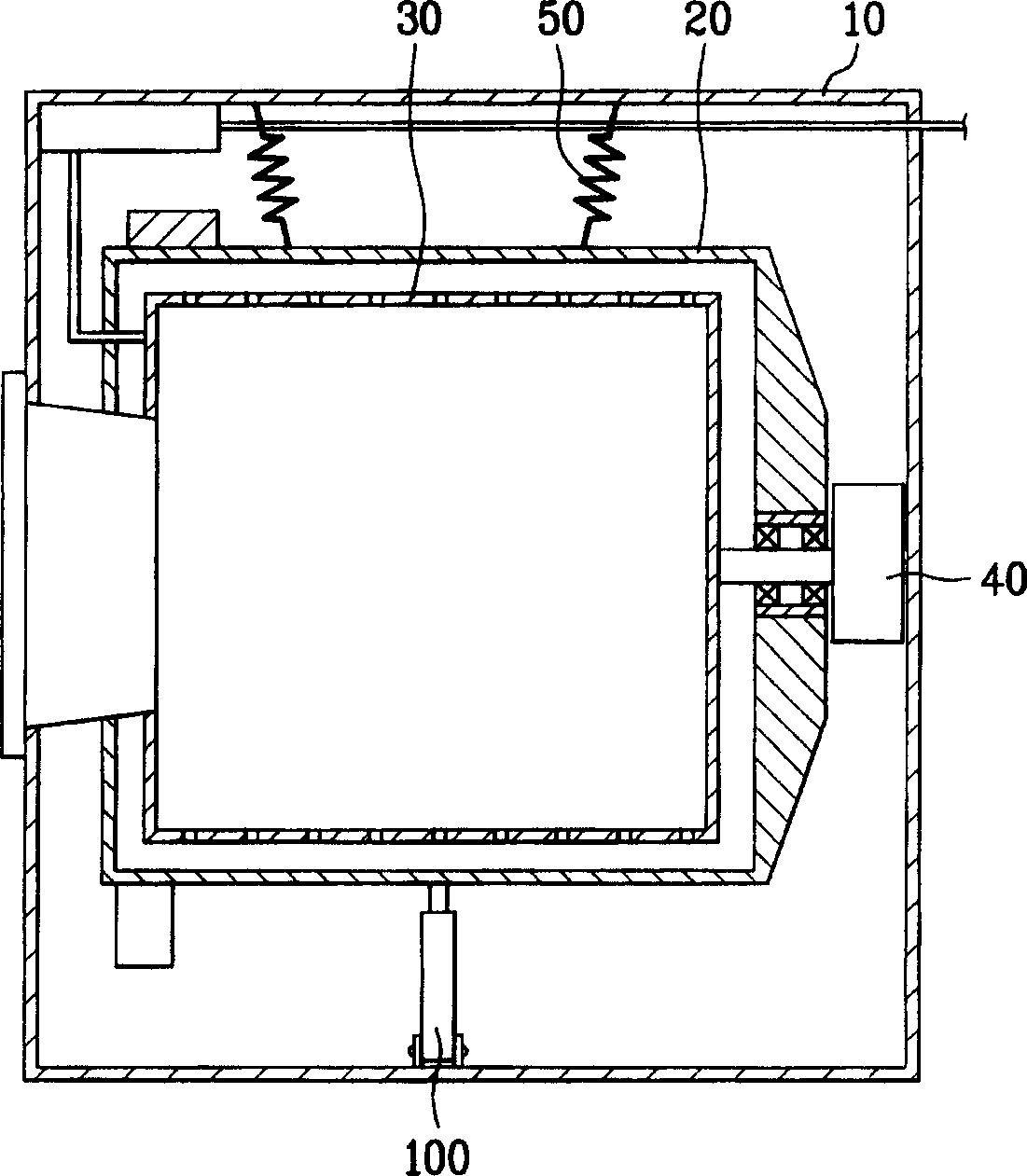

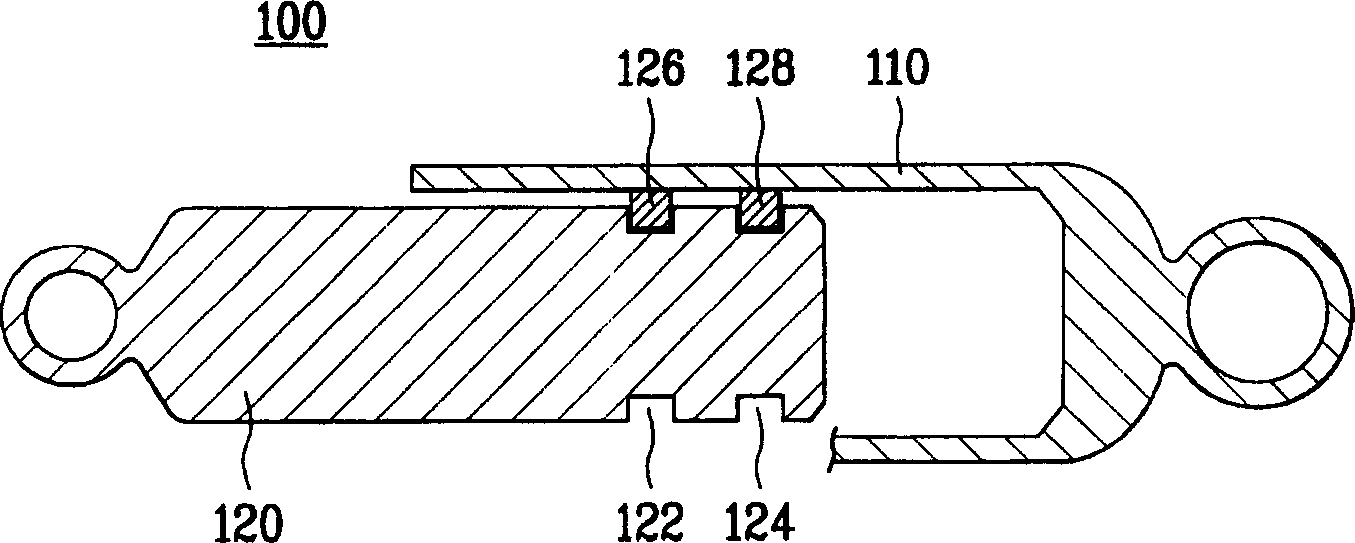

[0036] Figure 4 Is a cross-sectional view of the double shock absorption device of the washing machine of the present invention; Figure 5 It is an exploded schematic diagram of the shuttle ring of the double shock absorption device of the washing machine of the present invention.

[0037] As shown in the figure, the double shock absorber 200 (hereinafter referred to as friction shock absorber) for washing machine of the present invention includes a cylinder 210, a piston 220, a first shock absorber, and a second shock absorber. The cylinder 210 is in a hollow state. The piston 220 reciprocates inside the cylinder 210; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com