Fuel pump brush performance testing workbench

A technology for testing workbenches and fuel pumps, applied in electrical components, circuit/collector parts, circuits, etc., can solve the problem of lack of automatic high-speed testing equipment, etc., and achieve fast testing speed, reduce production costs, and shorten testing cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

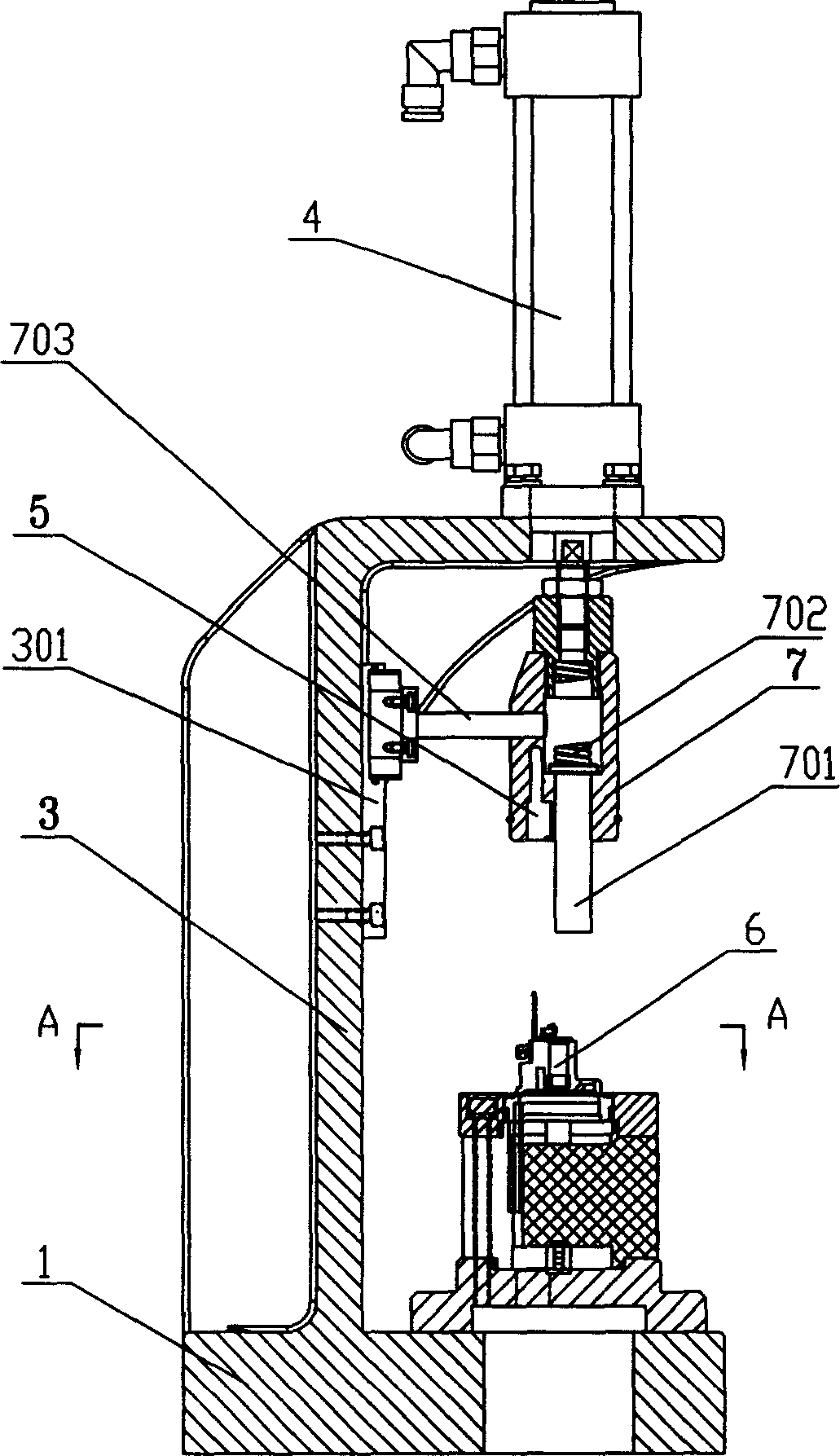

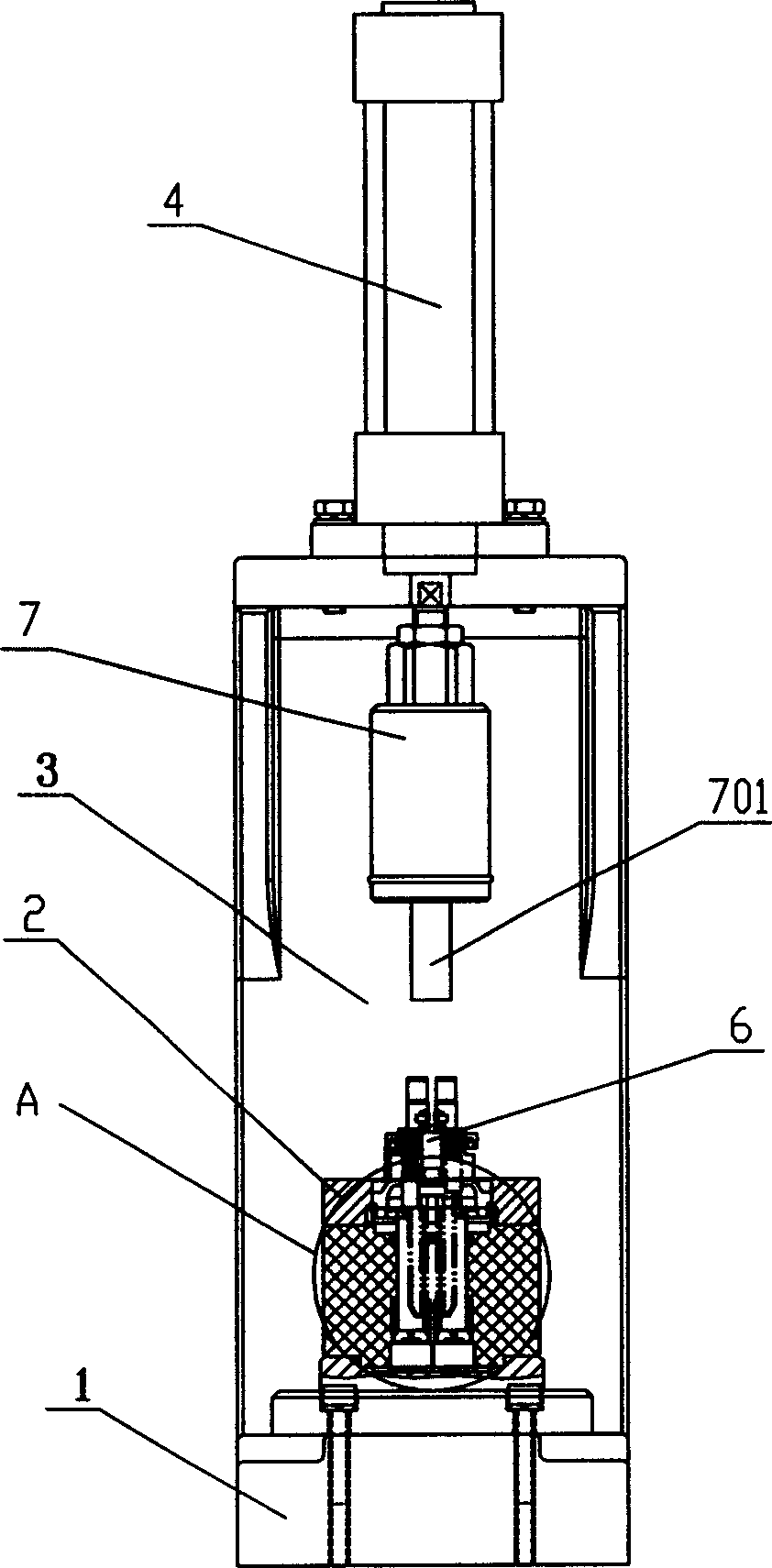

[0031] The embodiment of the present invention is a test bench for detecting the resistance of the connecting piece of the fuel pump brush and the pressure performance of the compression spring in a production line, that is, the automatic high-speed testing workbench for the resistance of the connecting piece of the brush of the automobile fuel pump and the pressure of the compression spring.

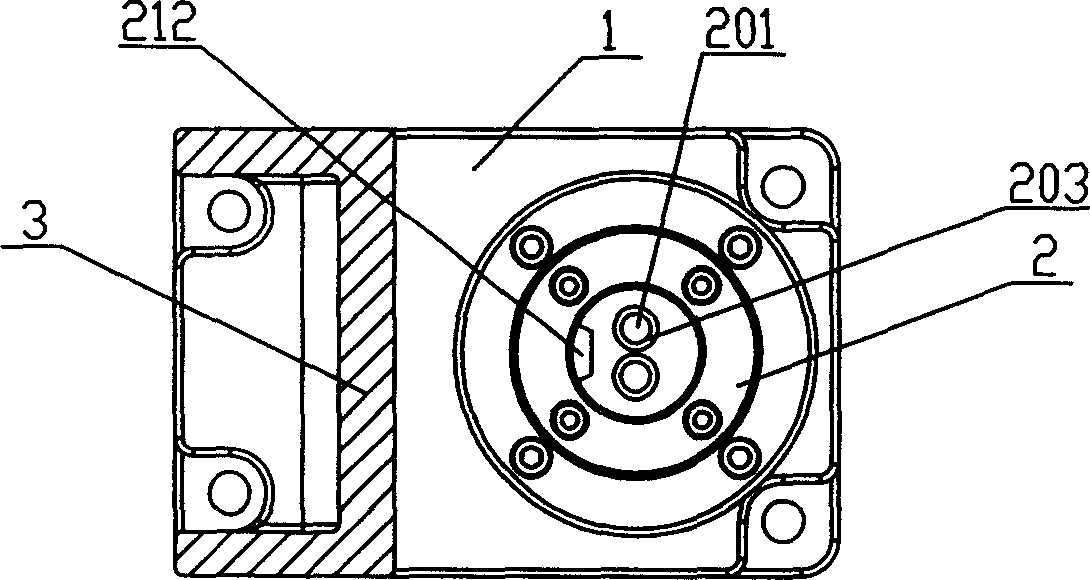

[0032] Such as figure 1 , 3 As shown, the fuel pump brush connector performance test bench includes a base 1, a bracket 3 arranged on the base 1, and a propulsion mechanism 4 arranged on the bracket 3; the lower part of the propulsion mechanism 4 is provided with a pressure head 7, and The lower part is provided with a socket (original fuel pump power supply wiring socket) 5 for docking with the plug of the brush holder under test; the base 1 below the propulsion mechanism 4 is provided with a brush holder fixture 2; Test the two contacts connected by the two brushes in the brush holde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com