Calendered industrial process fabric

A fabric and industrial technology, applied in the field of wet-laid products, which can solve problems such as shortening the service life of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

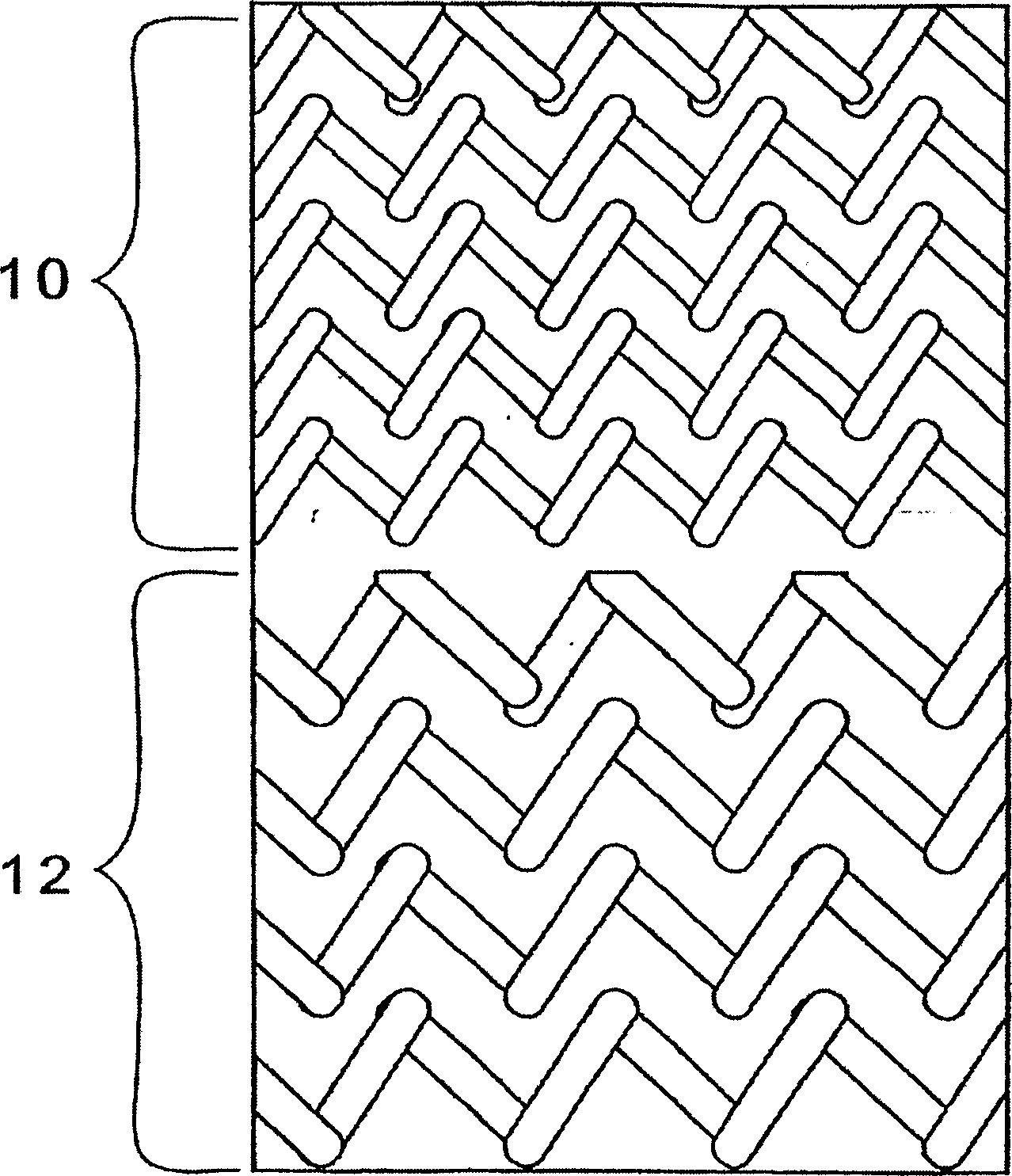

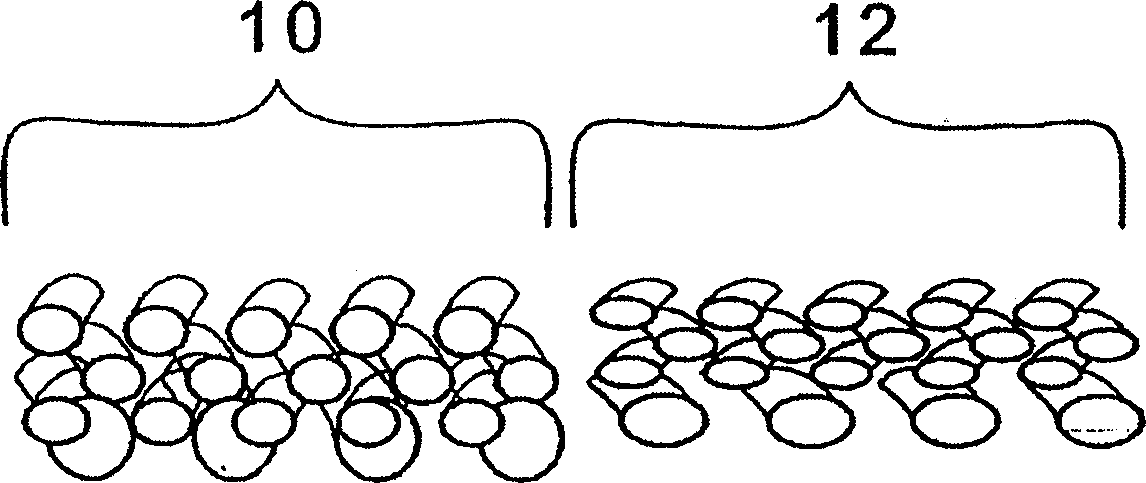

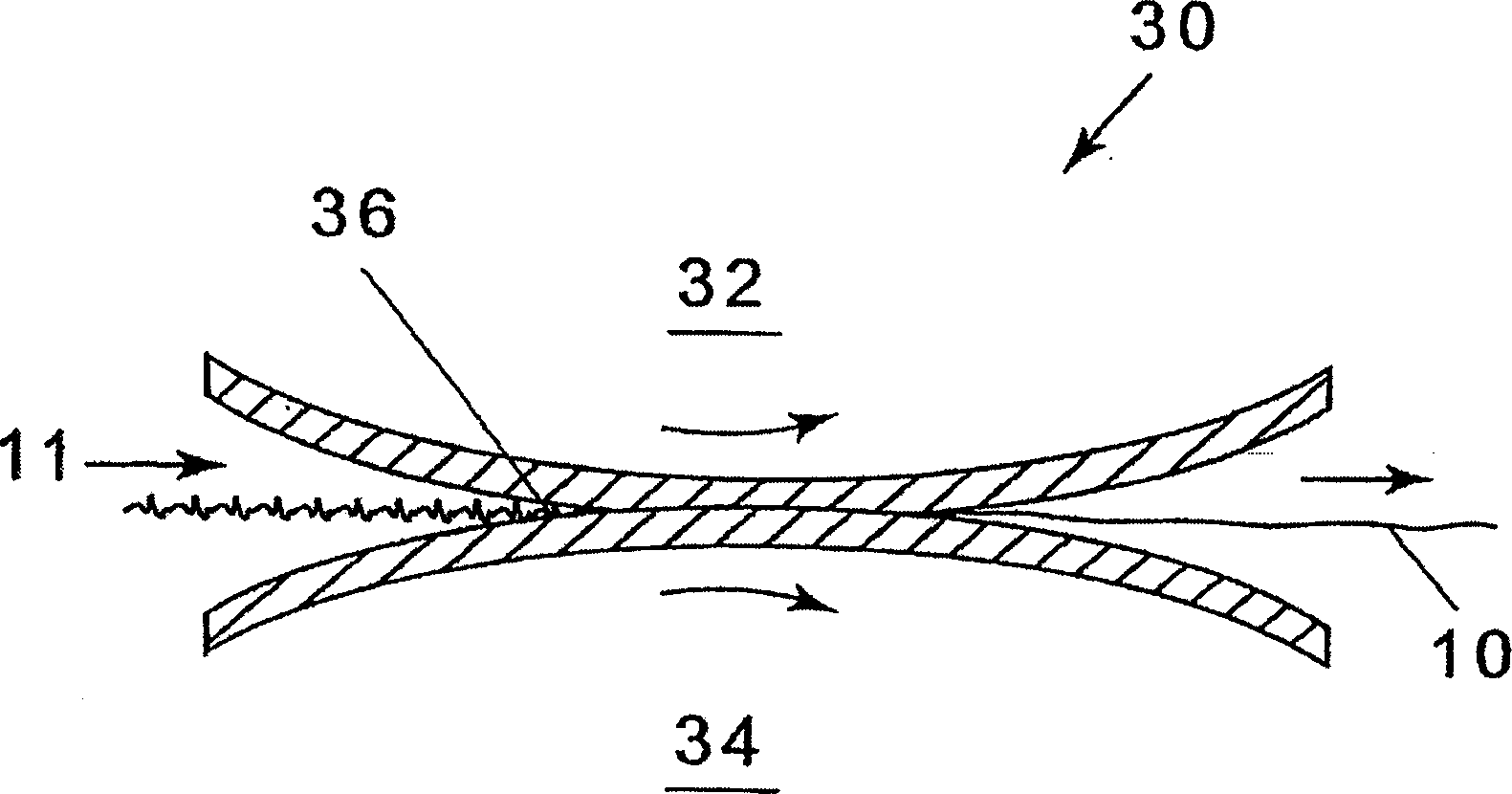

[0019] A preferred embodiment of the invention will be described in the context of a forming fabric for a paper machine. It should be noted, however, that the invention is applicable to fabrics used on other sections of a paper machine, and to fabrics used in other industrial installations where the smoothness, planarity and controlled permeability and Breathability is very important. Examples of other fabric types suitable for use in the present invention include paper machine press fabrics, paper machine dryer fabrics, through-air drying fabrics, and pulp forming fabrics. Another example is fabrics used in papermaking related processes such as slurry filters and chemical washing machines. Examples of other fabric types suitable for use in the present invention are engineered fabrics, such as those used in the manufacture of nonwovens by wet-laid, dry-laid, meltblown and / or spunbond processes.

[0020] Furthermore, the invention is generally described in terms of calendered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com