Vulcanizing agent system for fluororubber, fluororubber compound and application

A fluororubber raw rubber and fluororubber technology, applied in the field of fluororubber, can solve problems such as poor fluororubber performance, and achieve the effects of good chemical resistance and low compression set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of CF 3 C(C 6 H5OH) 3 : Add 650g of 1,1,1-tris(4-hydroxyphenyl)ethane and 1000ml of polyfluoroethanol into the autoclave, stir to make it dissolve evenly. Frozen brine was introduced into the jacket of the reaction kettle to keep the temperature of the reaction system below 5°C, and then fluorine gas was slowly introduced into the reaction kettle for 5 hours, then the fluorine gas was stopped, and the fluorine gas was blown off with nitrogen, and then vacuumed out to remove the remaining inside of the kettle gas. The reaction product was separated, filtered, washed and dried at low temperature to obtain 702 g of white solid, namely 1,1,1-tris(4-hydroxyphenyl)trifluoroethane (triphenol AF). The latter was determined to have a melting point of 246-252°C, 1 H-NMR spectrum: 9.105 (s, 2H, PH-OH), 6.726 (d, 4H, PH), 7.182 (d, 4H, PH).

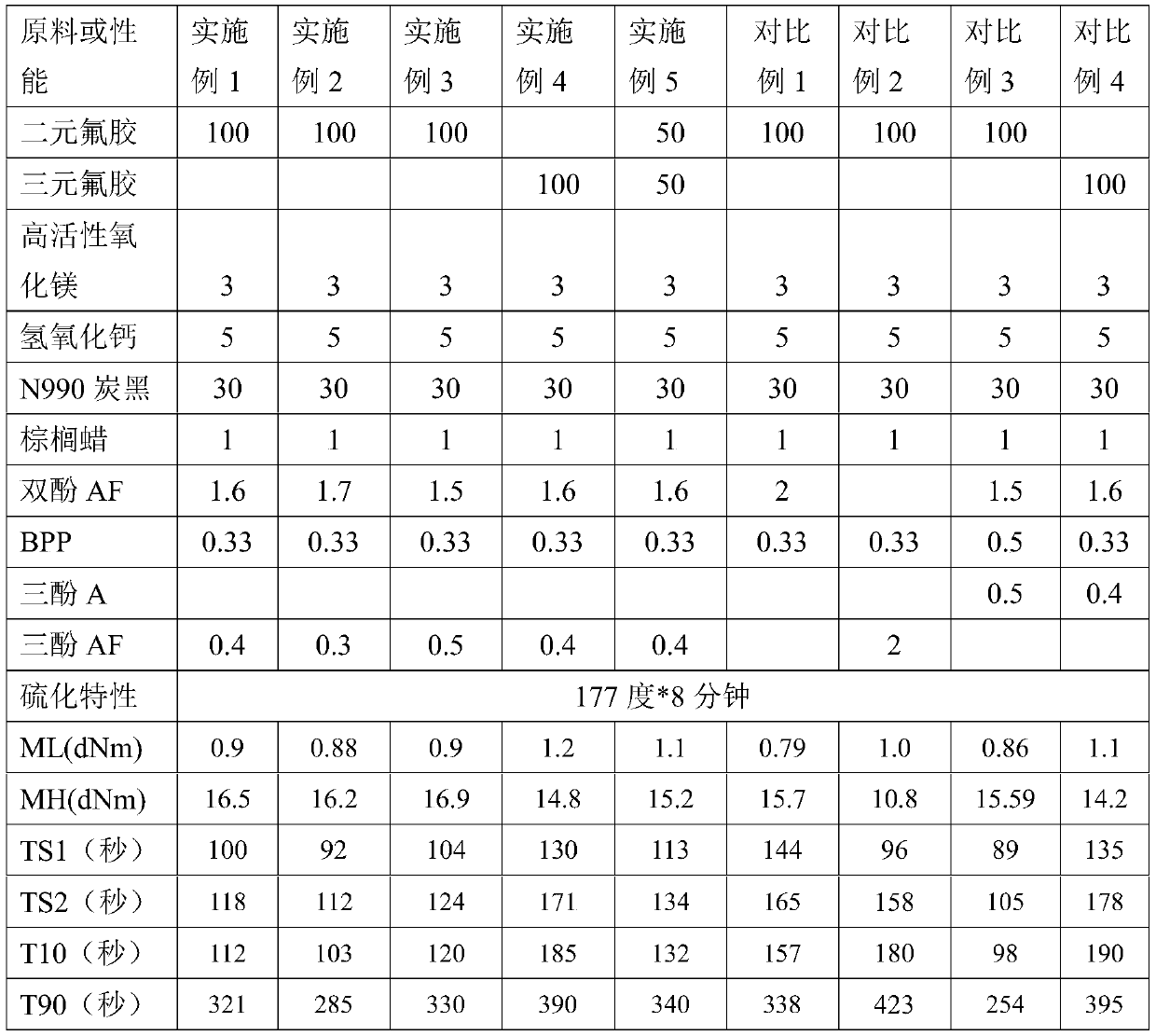

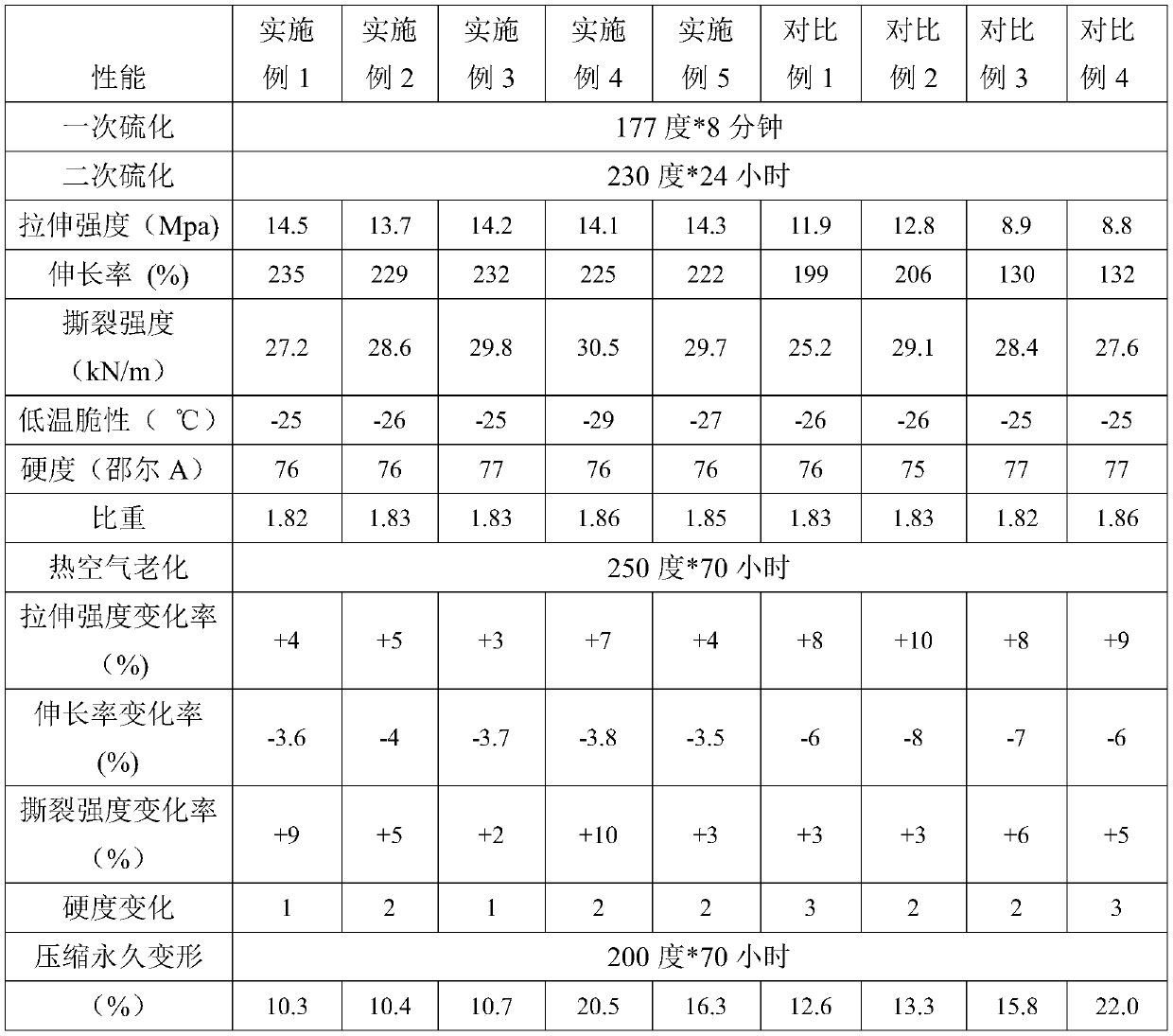

[0033]Put 100g of binary fluorine rubber on a two-roller mixer for 5 minutes, then add 3g of active magnesium oxide, 5g of c...

Embodiment 2

[0035] Change the amount of bisphenol AF to 1.7g and the amount of triphenol AF to 0.3g, and other conditions are the same as in Example 1. The vulcanization properties of the obtained mixed rubber and the physical and chemical properties of the vulcanized rubber obtained through secondary vulcanization are measured and summarized respectively. In Table 1 and Table 2.

Embodiment 3

[0037] Change the amount of bisphenol AF to 1.5g and triphenol AF to 0.5g, and other conditions are the same as in Example 1. Measure the vulcanization properties of the obtained mixed rubber and the physical and chemical properties of the vulcanized rubber obtained through secondary vulcanization, and summarize them respectively In Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com