Thermoplastic polyurethane elastomer foam material composition and foam material

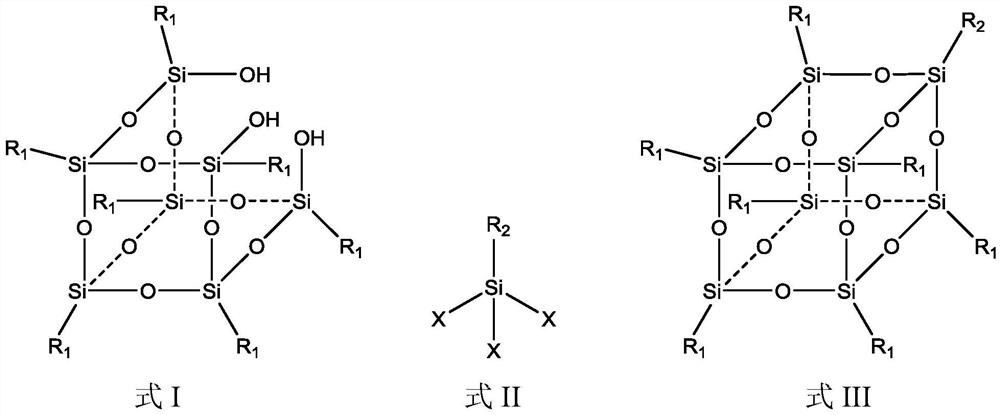

A technology of thermoplastic polyurethane and foaming materials, which is applied in the field of foaming materials, thermoplastic polyurethane elastomer foaming materials and their compositions, and can solve the problems affecting the performance of foamed products, the two-phase distribution of olefin polymers and TPU Uniformity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

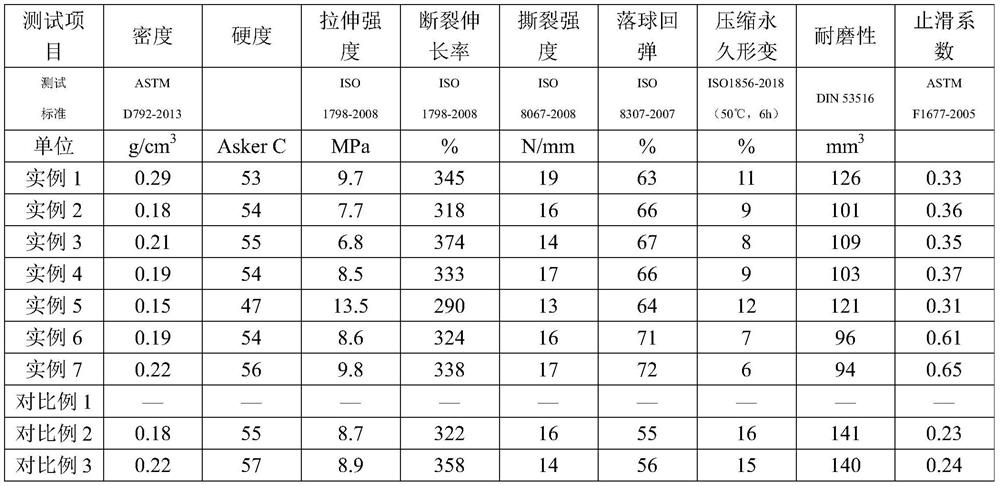

Embodiment 1

[0086] A thermoplastic polyurethane elastomer foam composition, by weight, comprises the following components:

[0087] Thermoplastic polyurethane elastomer (WHT-8175RV Wanhua Chemical) 95 parts;

[0088] 5 parts of trimethylolpropane triacrylate (Changxing Chemical);

[0089] 0.8 parts of dicumyl peroxide;

[0090] 2 parts of azodicarbonamide;

[0091] 1 part stearic acid;

[0093] The thermoplastic polyurethane elastomer foaming material in this example is prepared by the following method:

[0094] 1) Put thermoplastic polyurethane elastomer, trimethylolpropane acrylate, dicumyl peroxide, azodicarbonamide, stearic acid, and zinc oxide into an internal mixer, and mix for 15 minutes at a temperature of 115°C. A foamable composition is prepared.

[0095] 2) Put the foamable composition obtained in step 1) into a flat vulcanizing machine for molding and foaming. The foaming temperature is 170° C., the pressure is 30 MPa, the foaming time is 20 ...

Embodiment 2

[0098] A thermoplastic polyurethane elastomer foam composition, by weight, comprises the following components:

[0099] Thermoplastic polyurethane elastomer (WHT-1180 Wanhua Chemical) 90 parts;

[0100] 10 parts of liquid oligomer polybutadiene (N4-9000 Xin Tema company);

[0101] 0.5 parts of dicumyl di-tert-butyl peroxide;

[0102] 3.5 parts of azodicarbonamide;

[0103] 1 part stearic acid;

[0105] The thermoplastic polyurethane elastomer foaming material in this example is prepared by the following method:

[0106] 1) Put thermoplastic polyurethane elastomer, liquid oligomer polybutadiene, dicumyl bis-tert-butyl peroxide, azodicarbonamide, stearic acid and zinc oxide in an internal mixer and knead, mix The kneading time is 15 minutes and the temperature is 115° C. to prepare a foamable composition.

[0107] 2) Put the foamable composition obtained in step 1) into a flat vulcanizing machine for molding and foaming. The foaming temperature...

Embodiment 3

[0110] A thermoplastic polyurethane elastomer foam composition, by weight, comprises the following components:

[0111] Thermoplastic polyurethane elastomer (WHT-1170IC Wanhua Chemical) 85 parts;

[0112] Liquid oligomer polyisoprene (IR-565 Lin's Chemical) 15 parts;

[0113] 1 part of dicumyl bis-tert-butyl peroxide;

[0114] 5 parts of p-toluenesulfonyl hydrazide;

[0115] 1 part stearic acid;

[0116] Zinc oxide 2 parts.

[0117] The thermoplastic polyurethane elastomer foaming material in this example is prepared by the following method:

[0118] 1) Put thermoplastic polyurethane elastomer, liquid oligomer polyisoprene, dicumyl bis-tert-butyl peroxide, p-toluenesulfonyl hydrazide, stearic acid and zinc oxide in an internal mixer for mixing, The mixing time was 15 minutes and the temperature was 115° C. to prepare a foamable composition.

[0119] 2) Put the foamable composition obtained in step 1) into a flat vulcanizing machine for molding and foaming. The foaming te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com