Trochoid pump

A trochoid pump, pump chamber technology, applied in the direction of pumps, pump components, rotary piston type/swing piston type pump components, etc., can solve problems such as reducing pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

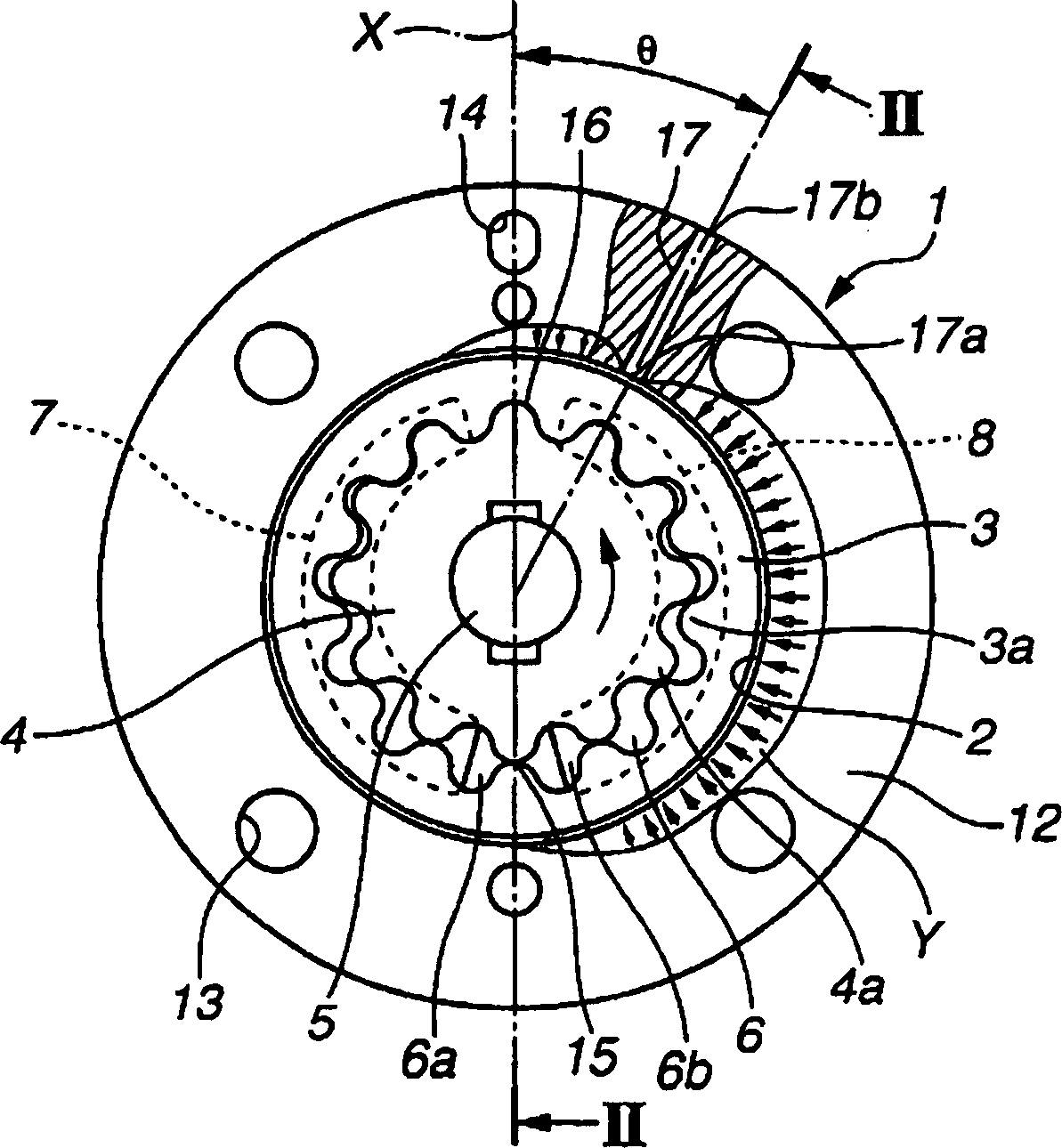

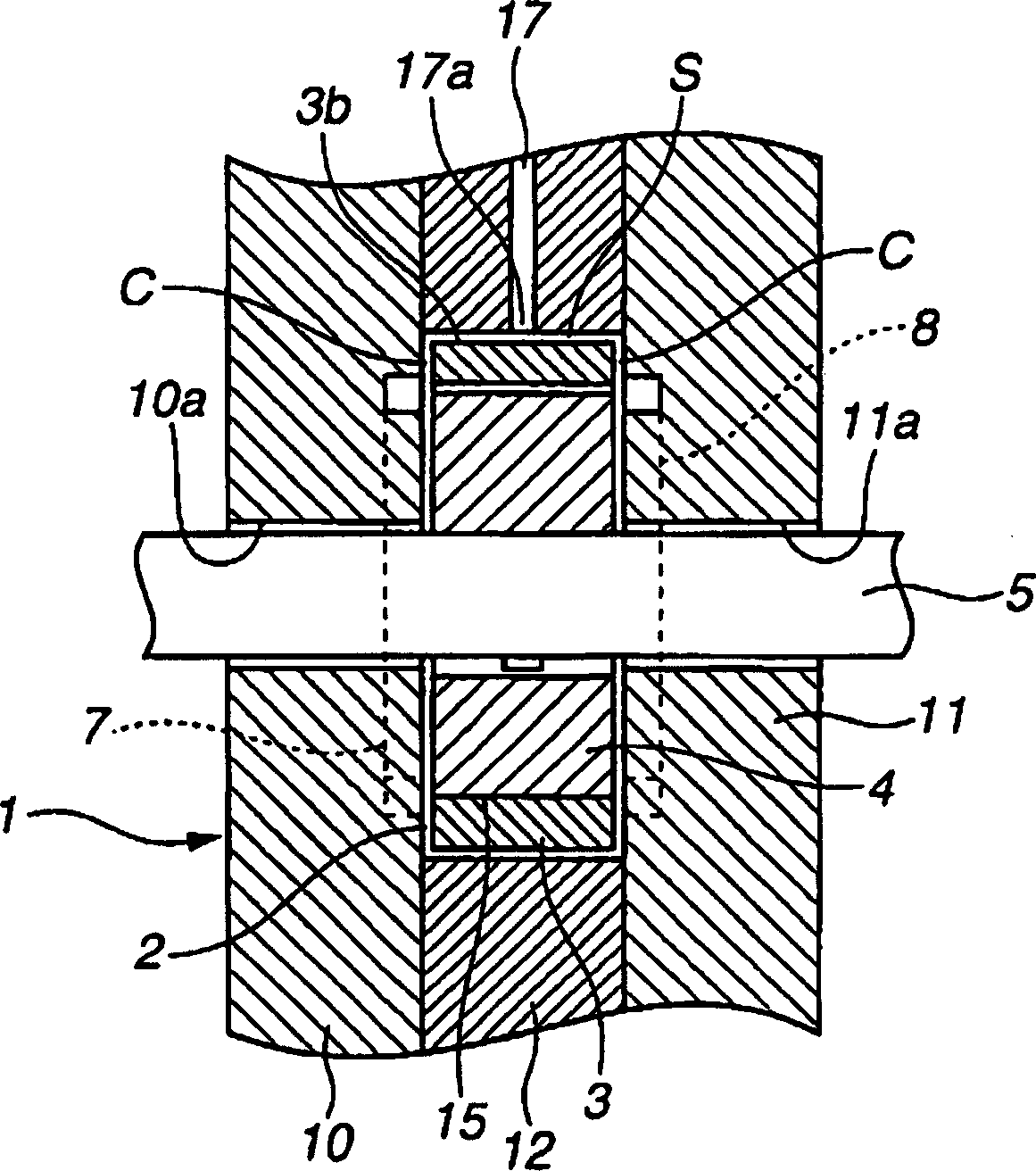

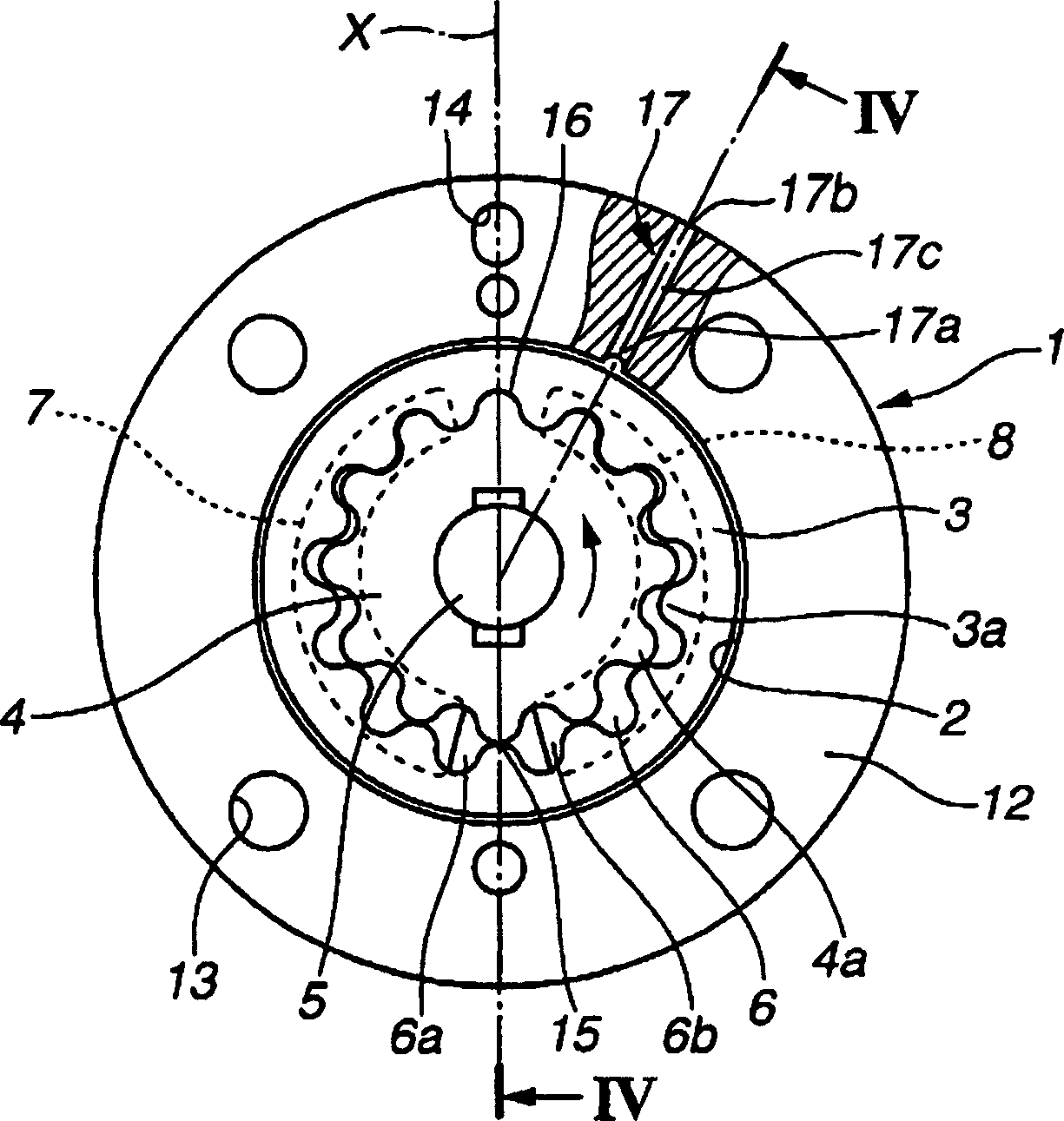

[0033] Refer below figure 1 and 2 , the figure shows the first embodiment of the trochoid pump (inscribed type gear pump) of the present invention. The trochoid pump selectively supplies hydraulic pressure to two hydraulic chambers of a hydraulic cylinder to help increase the steering force of a power steering system of a vehicle (automobile).

[0034] The trochoid pump includes a housing 1 in which is formed an annular operating chamber 2 formed on the inner peripheral side of a cam ring 12 (described later). The outer rotor 3 is rotatably fitted into the operation chamber 2, and has a plurality of internal teeth 3a continuously formed on the inner peripheral side of the outer rotor 3 in the circumferential direction. The inner rotor 4 is rotatably arranged inside the outer rotor 3 and has a plurality of outer teeth 4 a continuously formed in the circumferential direction of the inner rotor 4 . The outer teeth 4 a of the inner rotor 4 can mesh with the inner teeth 3 a of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com