Vehicular marker lamp

一种标识灯、车辆的技术,应用在车辆用标识灯领域,能够解决不能充分地均匀照射前透镜等问题,达到提高光束利用率、实现薄型化、减小深度尺寸的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

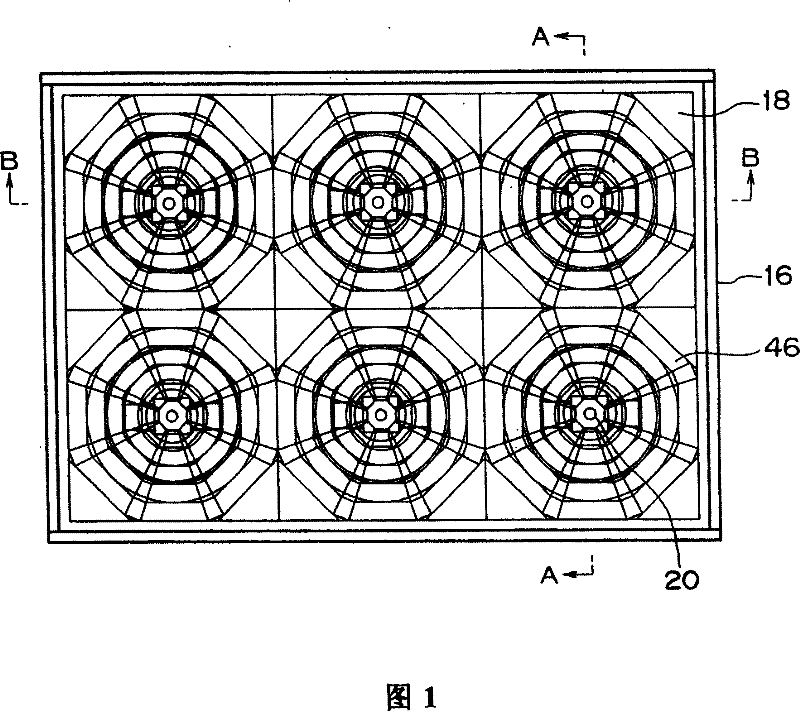

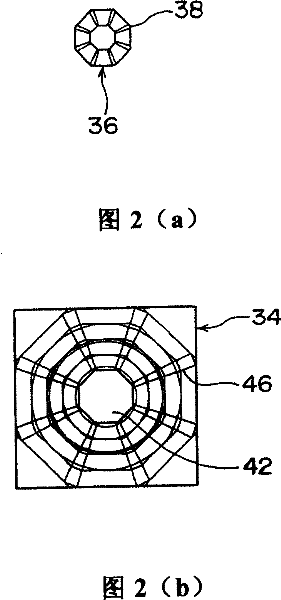

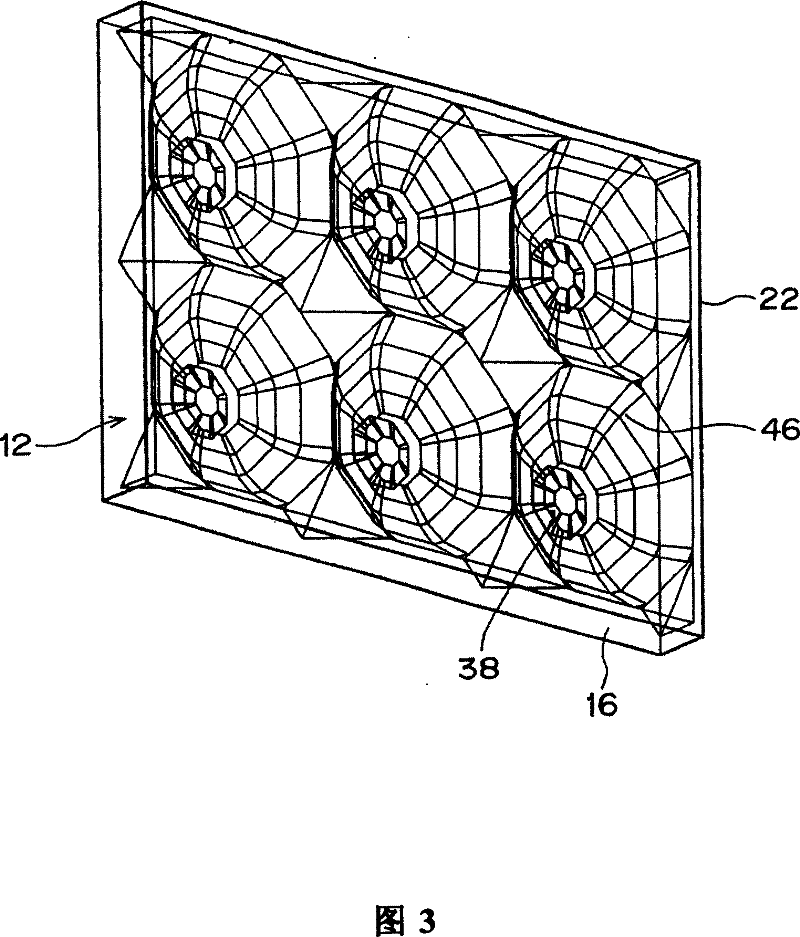

[0031] Hereinafter, embodiments of the present invention will be described based on examples. figure 1 It is a front view showing a vehicle marker lamp according to an embodiment of the present invention, and Fig. 2(a) is in figure 1 The structural diagram of the radial lens step (lens step) formed on the front side of the lens used in the shown vehicle marker lamp, FIG. 2(b) is a structural diagram of the radial lens step formed on the rear side of the same lens, image 3 yes figure 1 The oblique view of the identification lamp for the vehicle shown, Figure 4 is along figure 1 The cross-sectional view of the A-A direction, Figure 5 is along figure 1 The cross-sectional view of the B-B direction, Image 6 It is a front view showing a vehicle marker lamp according to another embodiment of the present invention, and FIG. 7(a) is in Image 6 The structural diagram of the radial lens step formed on the front side of the lens used in the shown vehicle marker lamp, FIG....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com