Detection and control of diaphragm collapse in condenser microphones

一种电容式麦克风、膜片的技术,应用在电气元件、换能器电路、传感器保护电路等方向,能够解决没有公开电容式麦克风破裂检测和控制电路等问题,达到简单定制、大灵活性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

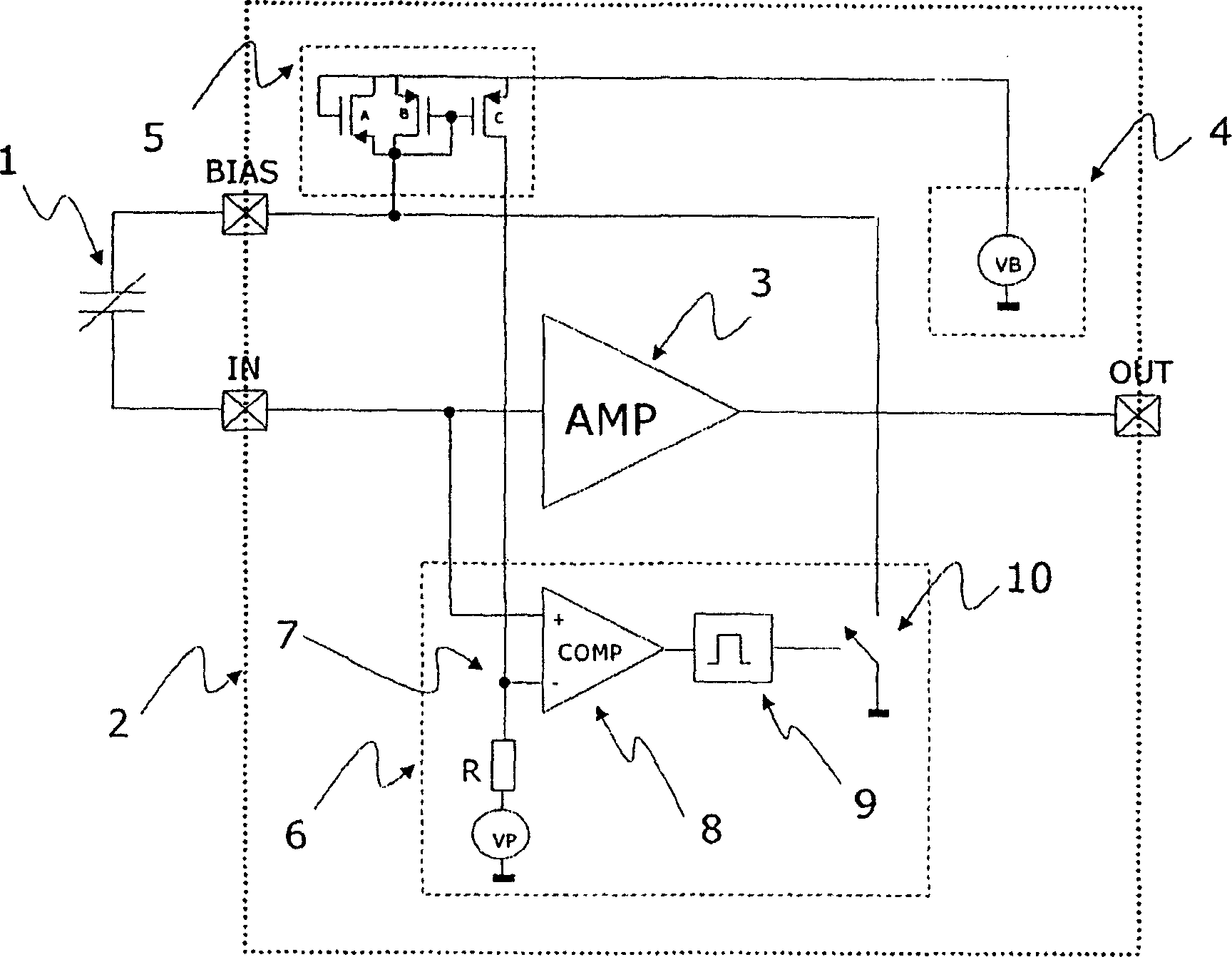

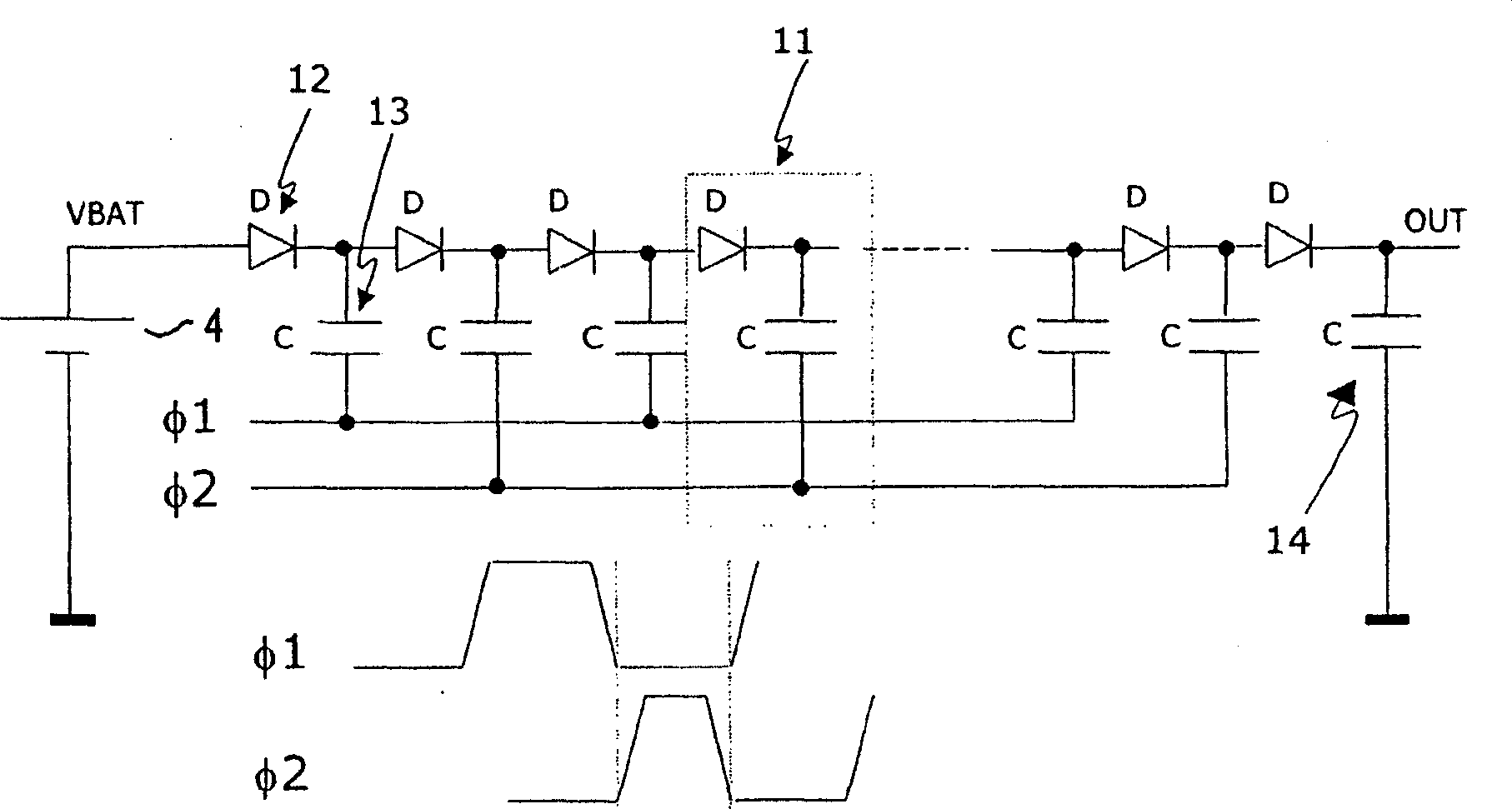

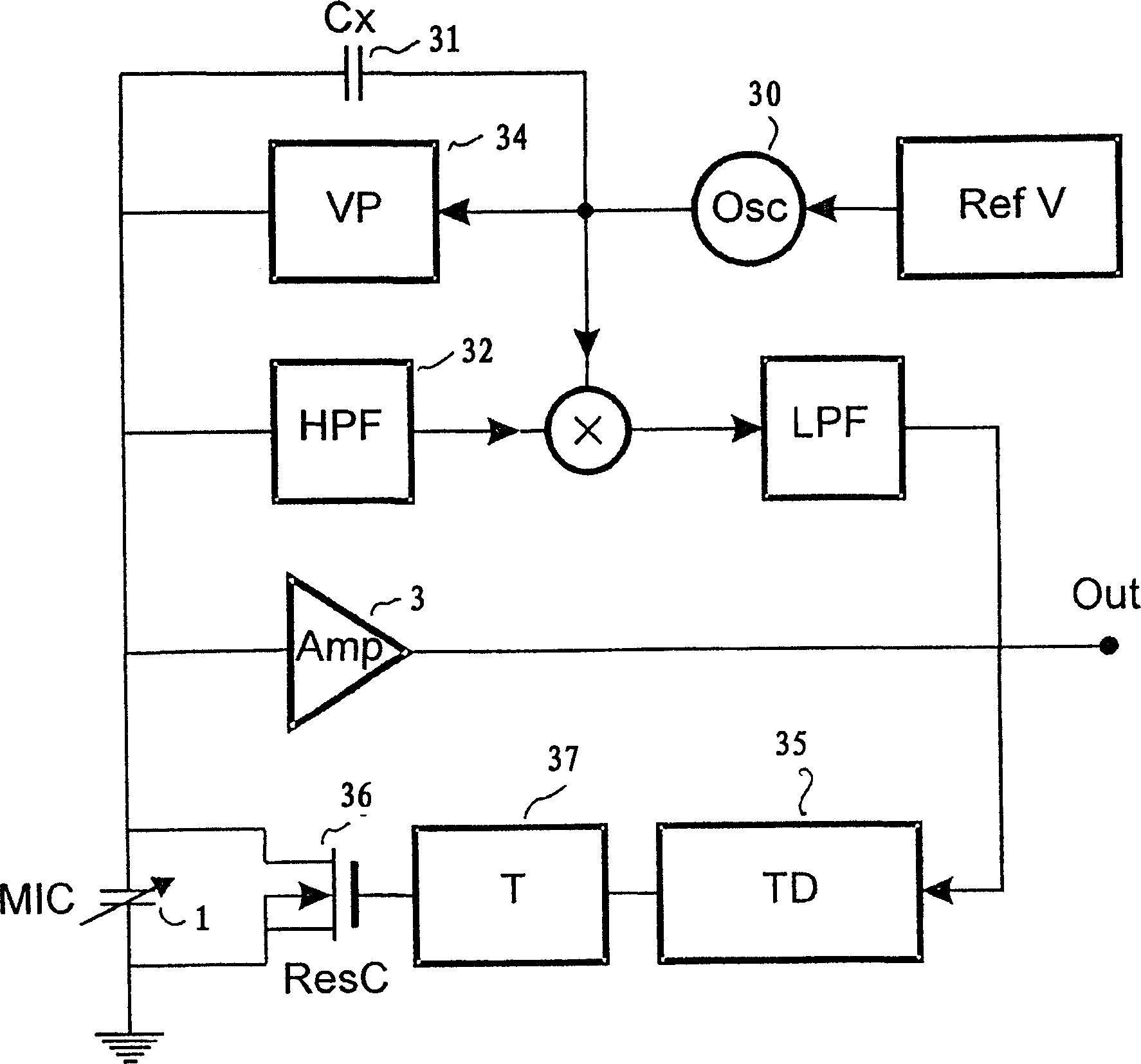

[0040] In the following embodiments, a break detection and control circuit suitable for integration into a small silicon-based condenser microphone will be described.

[0041] Several embodiments of the rupture detection circuit for detecting the distance between the diaphragm and the rear plate can be envisioned. Physical parameters such as voltage, capacitance and sound pressure can be used as described below. The detection circuit preferably makes the transducer element of the condenser microphone not load any significant impedance (relative to the generator impedance of the transducer element itself). The silicon transducer element of a MEMS microphone has a very large impedance, which basically corresponds to a capacitance of 5-20 pF, which makes meeting this requirement a great challenge.

[0042] Several embodiments of the rupture control circuit according to the present invention are also possible, some of them will be described below together with the detection circuit. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com