Calibration certification for wheel alignment equipment

A wheel alignment and wheel technology, applied to vehicle parts, instruments, measuring devices, etc., can solve the problems of not being able to provide toe-in confirmation and precision tracking capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

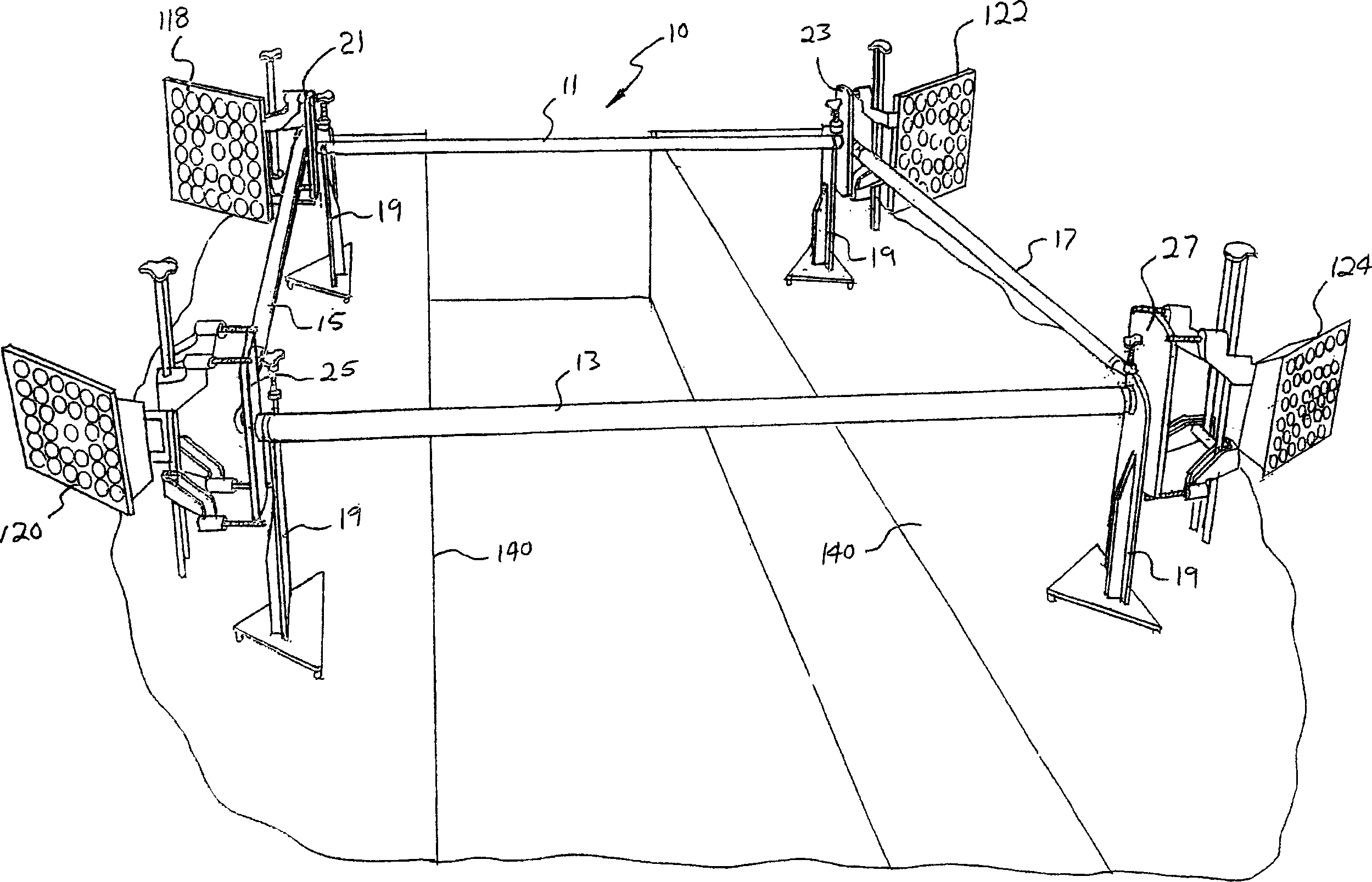

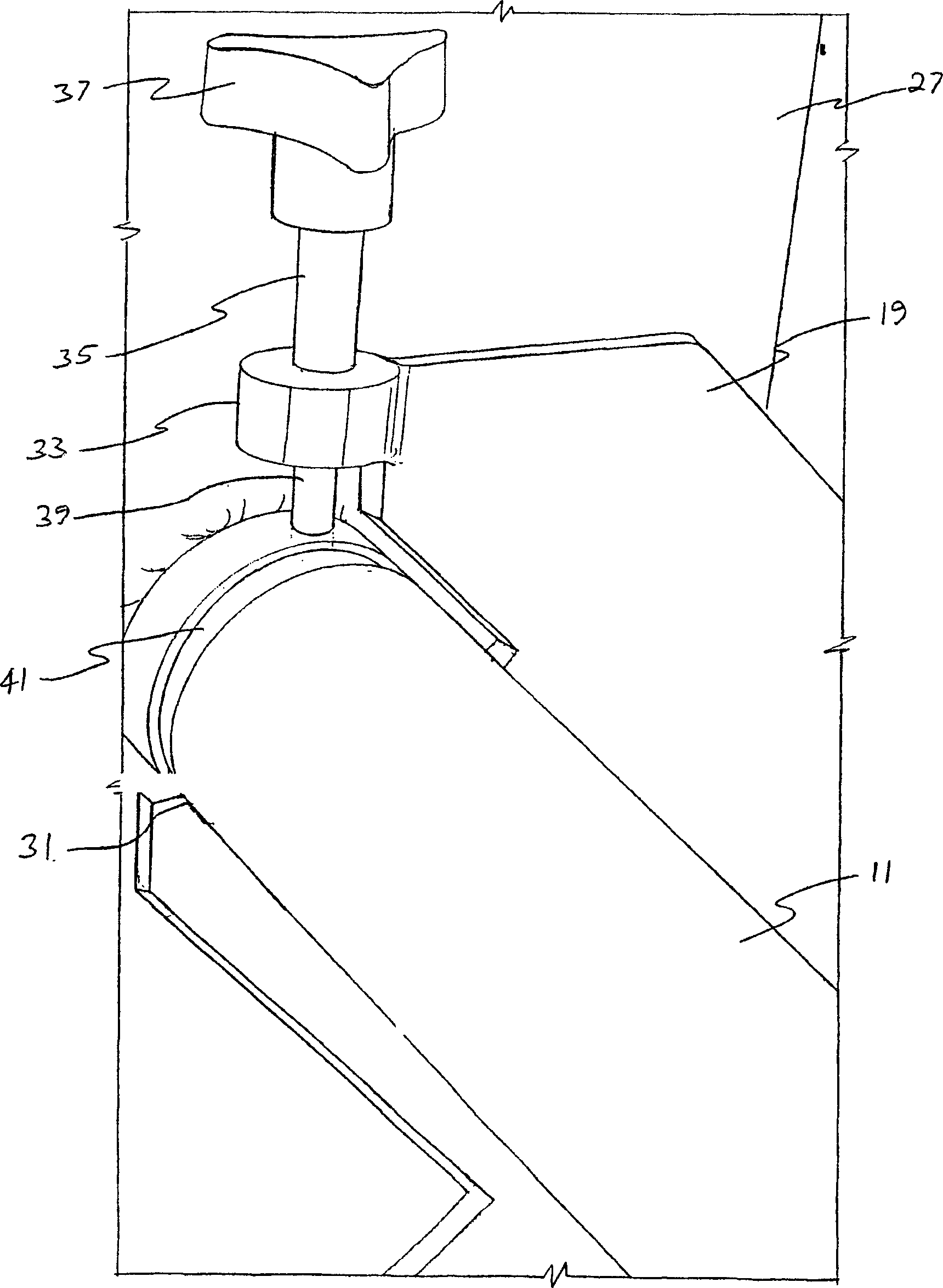

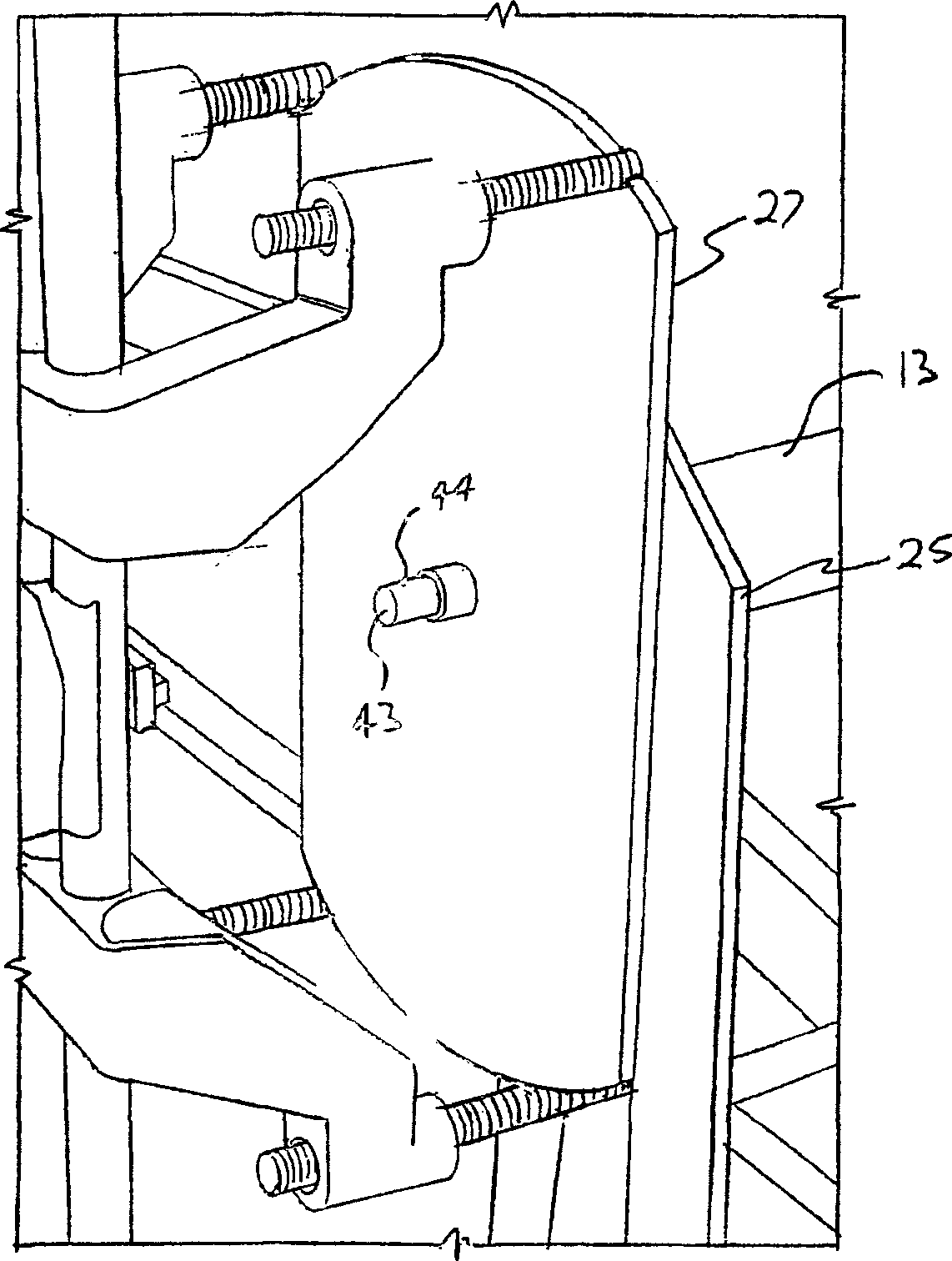

[0033] Various examples disclosed herein relate to systems and techniques for qualifying or verifying the performance accuracy of a wheel alignment system, and / or successfully calibrating the system.

[0034] Figures 1 to 15 shows various aspects of the assay device and its components. The exemplary apparatus or apparatus includes a verification fixture or fixture, and a distance setter for the lateral spacers and diagonal spacers for setting the diagonal distance of the verification fixture. The clamp includes a frame and a bracket on the frame for supporting the head of the wheel alignment system. The device is easy to handle. The frame is configured such that the bracket supports the head at a location adjacent to the wheelbase and track dimensions of a vehicle measurable by a wheel alignment device.

[0035] The method of verifying the calibration of the wheel aligner requires positioning the measuring head of the wheel aligner at several positions on a movable jig the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com