Cleansing method and cleansing liquid supplying device therefor

A technology for supplying devices and cleaning fluids, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., capable of solving problems that hinder the absorption of cleaning fluid conflict energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

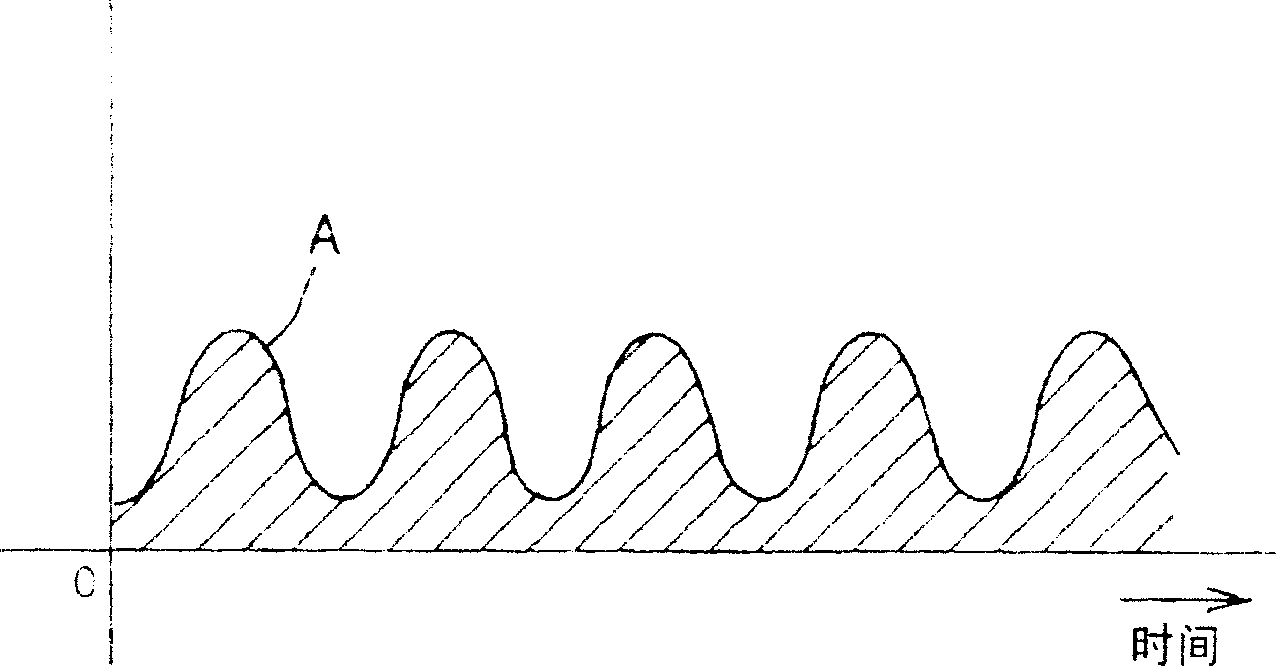

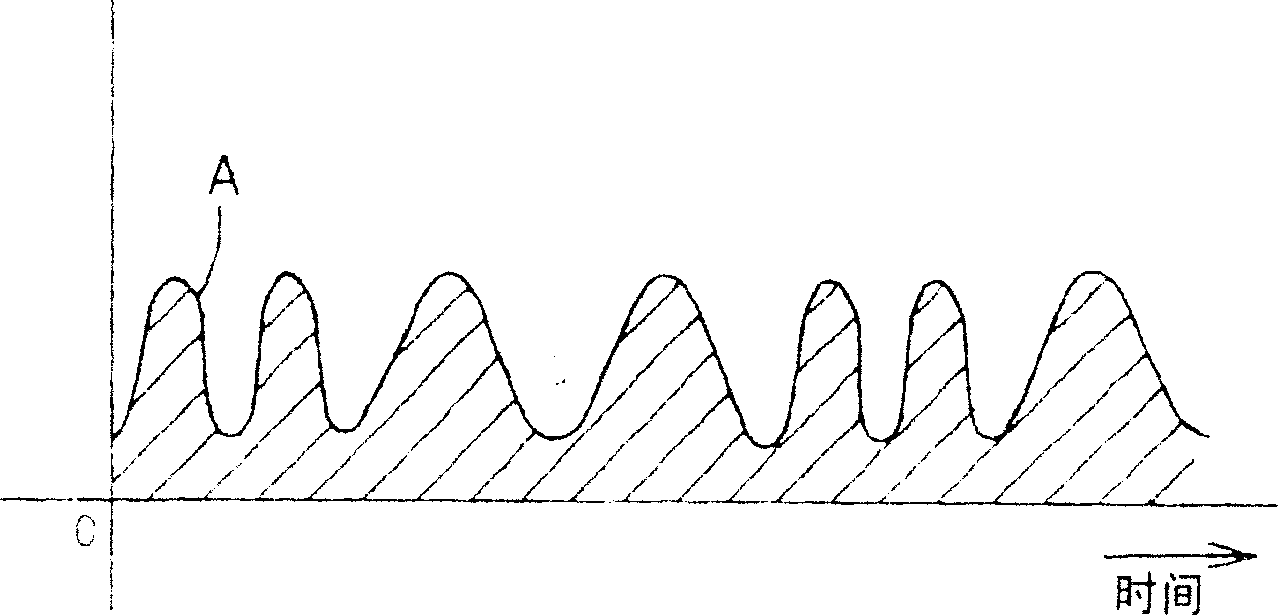

[0038] Below with reference to accompanying drawing, the embodiment of cleaning method of the present invention is described, figure 1It is a graph for explaining the cleaning method of this embodiment, and the horizontal direction in this figure represents the time axis. In addition, the symbol A in the figure represents the flow velocity of the cleaning liquid sprayed to the object to be cleaned, and the part indicated by the oblique line in the figure refers to the liquid amount of the cleaning liquid sprayed on the object to be cleaned.

[0039] That is, the cleaning method of this embodiment is characterized in that a predetermined amount of cleaning liquid is continuously sprayed to the object to be cleaned at ordinary times, and with this situation, the fluctuations are strengthened and weakened for the steady continuous flow of the continuously sprayed cleaning liquid. deal with.

[0040] In addition, in this embodiment, according to the flow rate of 14-17m / sec, the h...

Embodiment 2

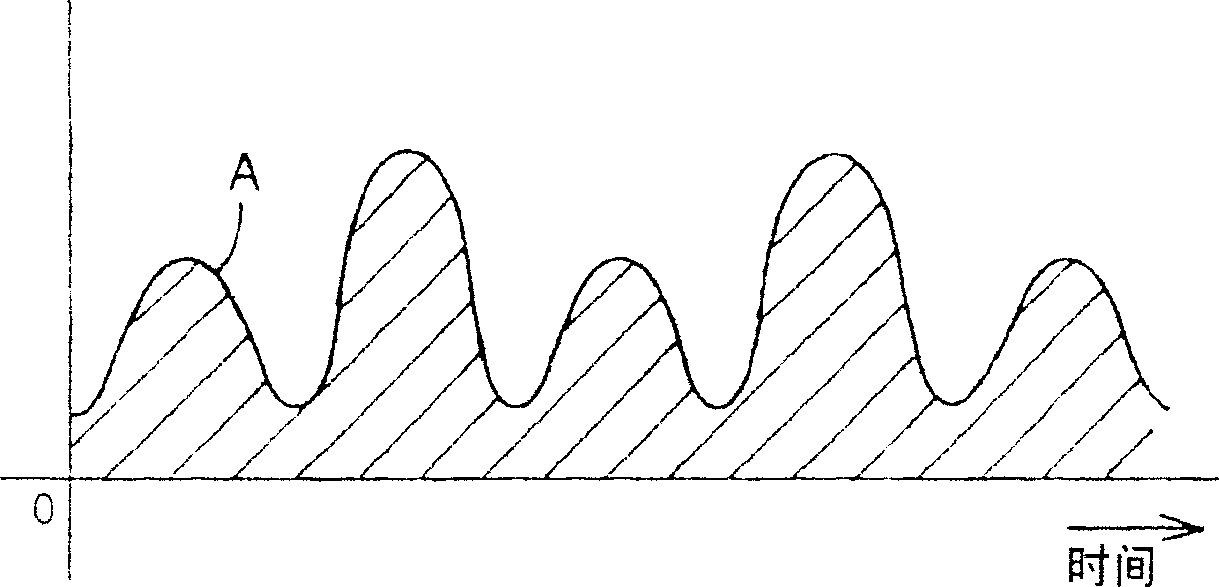

[0061] Another embodiment of the cleaning method of the present invention is described below with reference to the accompanying drawings, Figure 13 It is a graph for explaining the cleaning method of this embodiment. In the figure, the horizontal direction is the time axis.

[0062] In addition, in the cleaning method of this embodiment, a specified amount of cleaning liquid can be continuously sprayed to the object to be cleaned by high pressure at ordinary times, and in parallel with the spraying, another system of nozzles can be used to spray the cleaning liquid to the object by high pressure. The cleaning liquid that has been subjected to the treatment of increasing and decreasing fluctuations is blown onto the object to be cleaned.

[0063] which is, Figure 13 The symbol B among them represents the cleaning liquid that is sprayed continuously, and the symbol A represents the cleaning liquid that is sprayed according to the way of strengthening and weakening the fluctu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com