Pre-stressed concrete mixed beam structure with corrugated steel web

A corrugated steel plate and concrete technology, applied to structural elements, elongated structural members for load-bearing, bridges, etc., can solve complex problems such as joints that cannot be fastened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, preferred embodiments of the present invention will be specifically described with reference to the accompanying drawings.

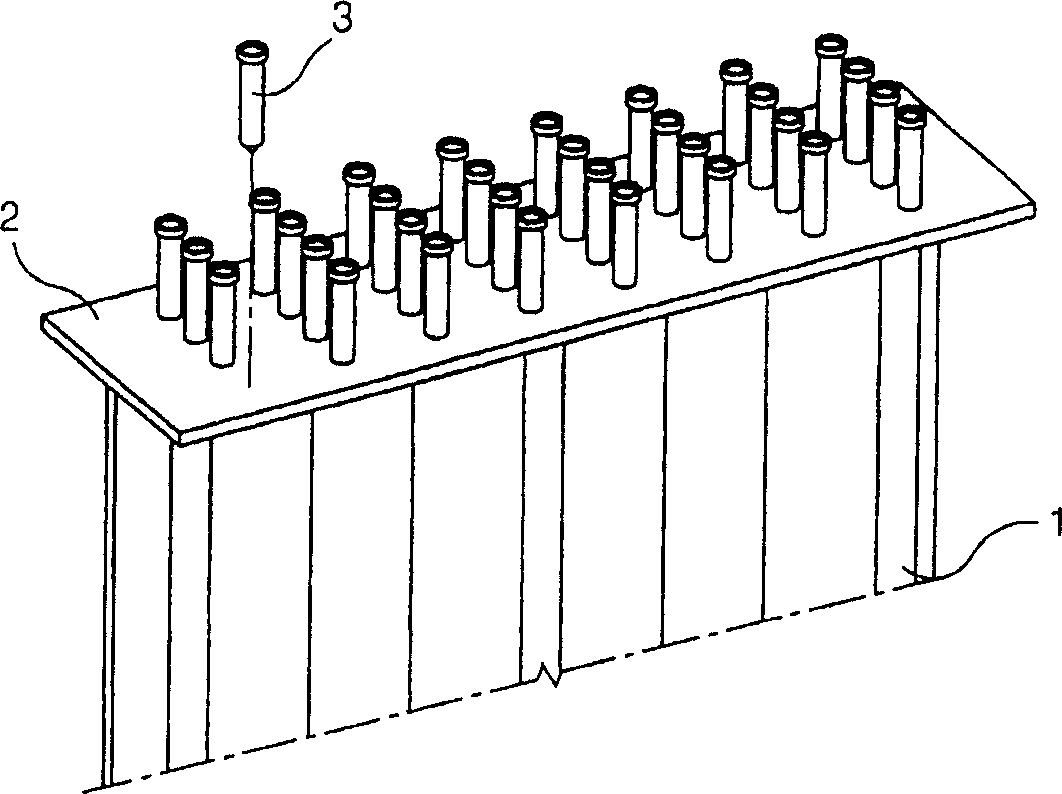

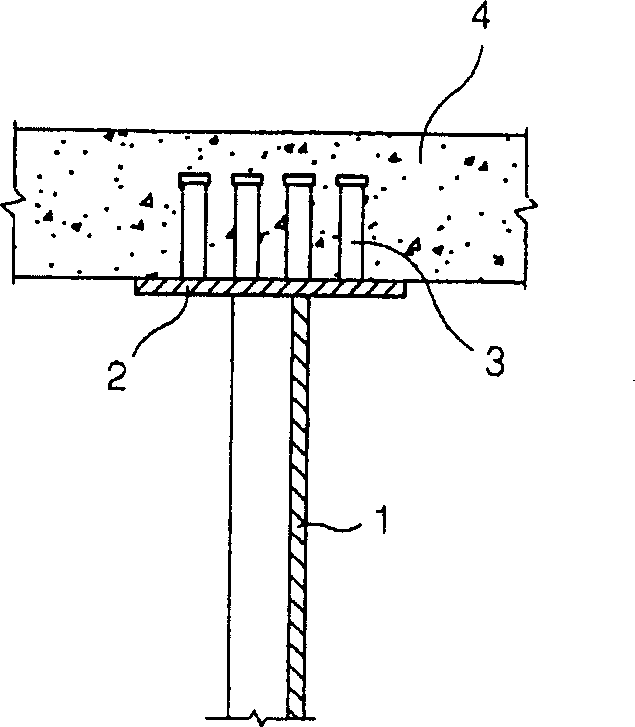

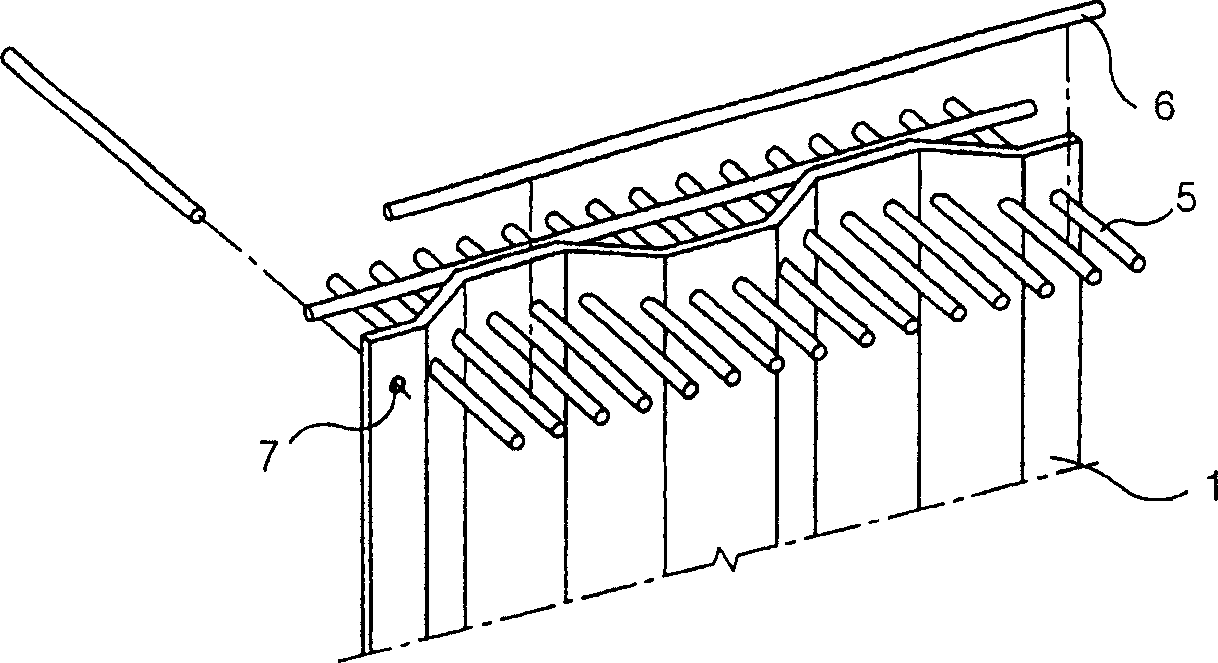

[0019] According to the preferred embodiment of the present invention, the structure of the prestressed concrete hybrid beam with corrugated steel plate web is constituted as follows. In order to enhance the bonding force when the corrugated steel plate is combined with concrete, the L-shaped steel 8 is placed on the corrugated steel plate 1 in a symmetrical manner relative to the vertical direction. The upper end and the lower end are combined with the corrugated steel plate 1, the vertical surface of the L-shaped steel plate 8 is combined with the corrugated steel plate 1 through the joint bolt 9, and many pillars 3 are connected on the horizontal surface of the L-shaped steel plate 8 by welding, and arranged on the upper and lower ends of the corrugated steel plate 1 The L-shaped steel 8 and the pillar 3 are integrally embedded in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com