High-frequency apparatus

A high-frequency equipment, front panel technology, applied in the direction of electrical equipment structural parts, electrical equipment housing/cabinet/drawer, electrical components, etc. Problems such as large circuit substrates, to achieve the effect of increasing density, shortening length, and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

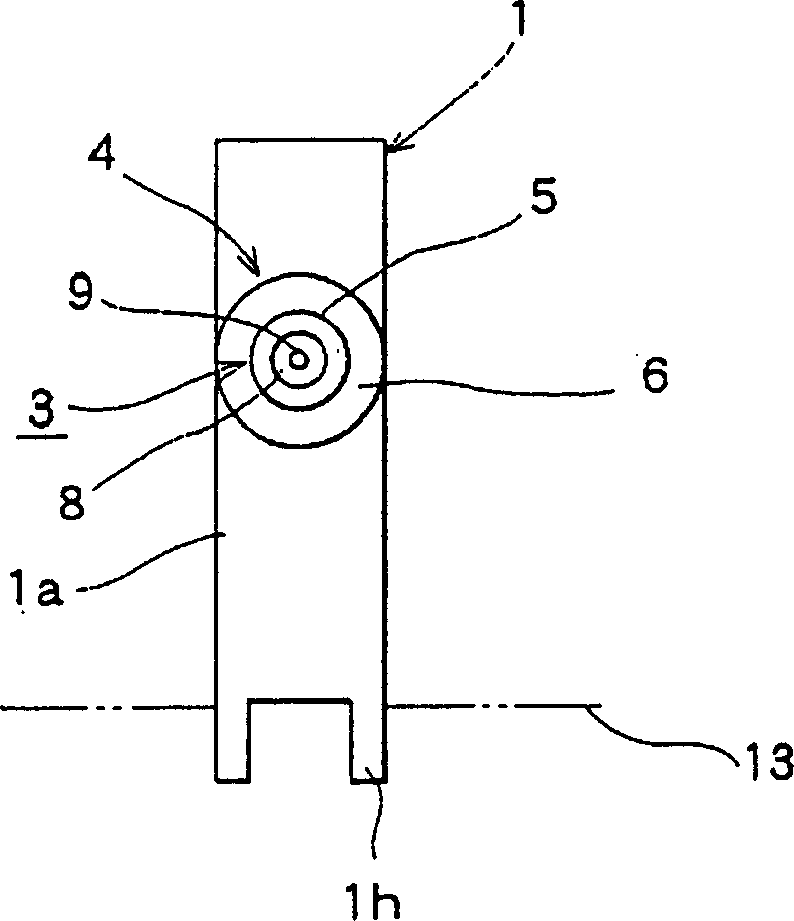

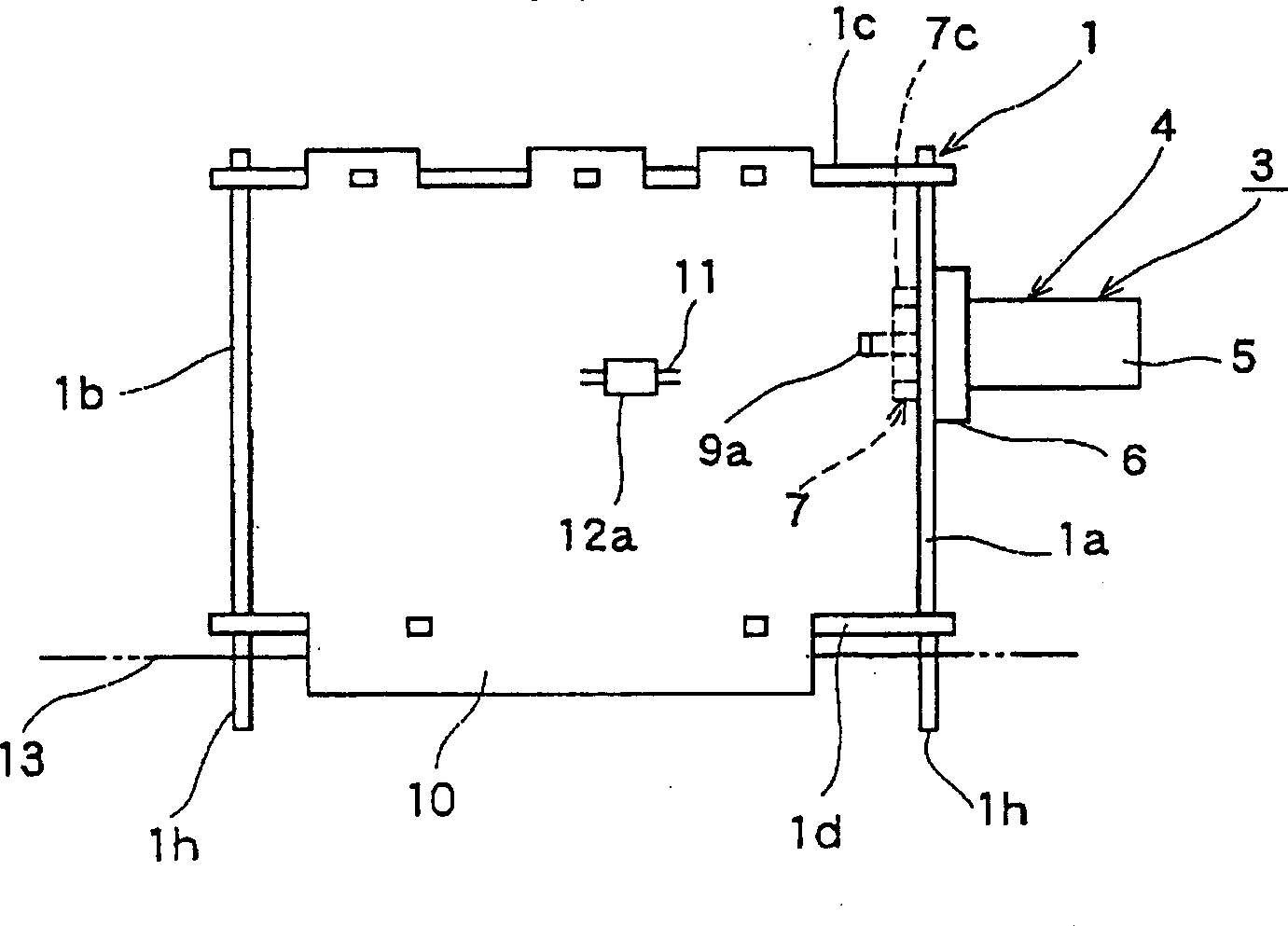

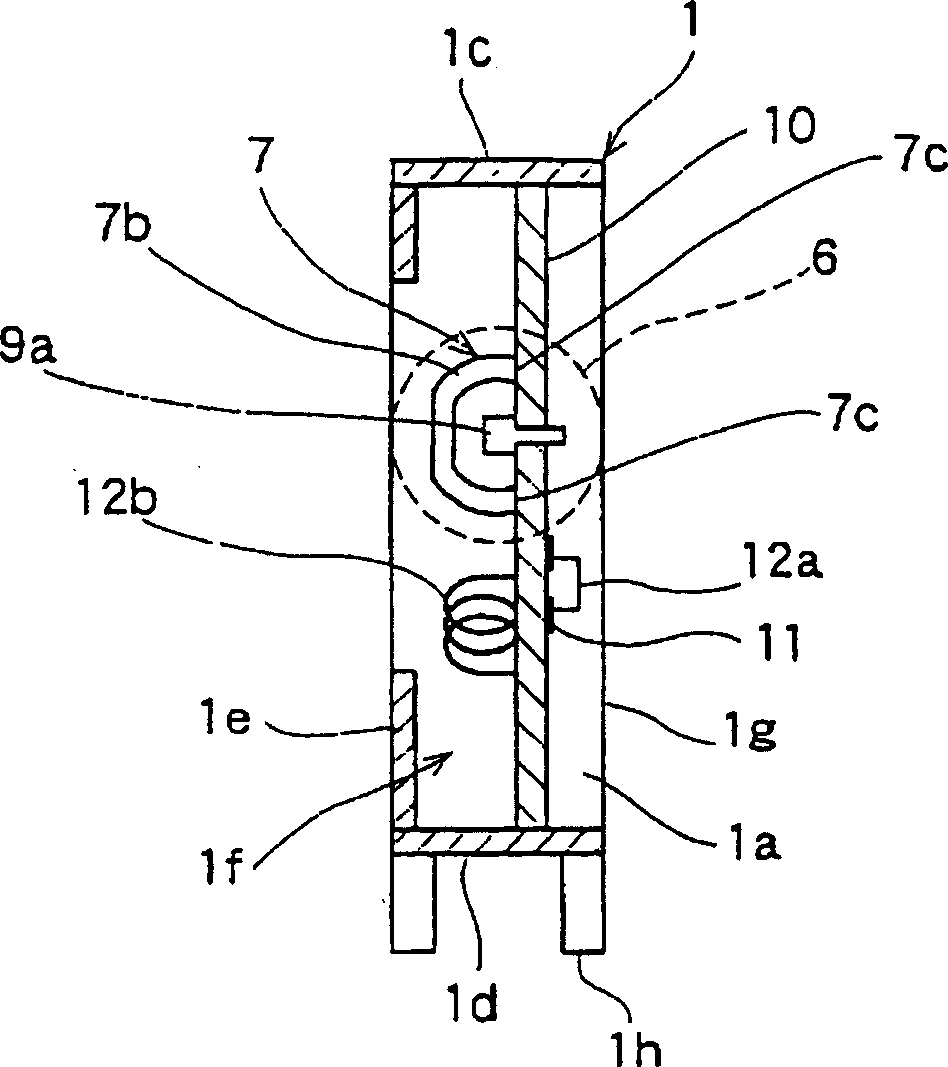

[0040] The accompanying drawings of the high-frequency equipment of the present invention are described, then figure 1 It is a front view of the first embodiment of the high-frequency device of the present invention, figure 2 It is a side view of the first embodiment of the high-frequency device of the present invention, image 3 It is a sectional view of main parts of the first embodiment of the high-frequency device of the present invention, Figure 4 It is a perspective view of the housing of the first embodiment of the high-frequency device of the present invention, Figure 5 It is a perspective view of the coaxial connector of the first embodiment of the high-frequency equipment of the present invention, Image 6 It is a perspective view of the frame body of the second embodiment of the high-frequency equipment of the present invention, Figure 7 It is an enlarged cross-sectional view of a main part of a third embodiment of the high-frequency device of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com