Motor manufacturing line and its control method

A production line and motor technology, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of large-scale storage space in inventory warehouses, rising management costs, manufacturing costs, and storage time, etc., to shorten delivery time, reduce manufacturing costs, The effect of reducing delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

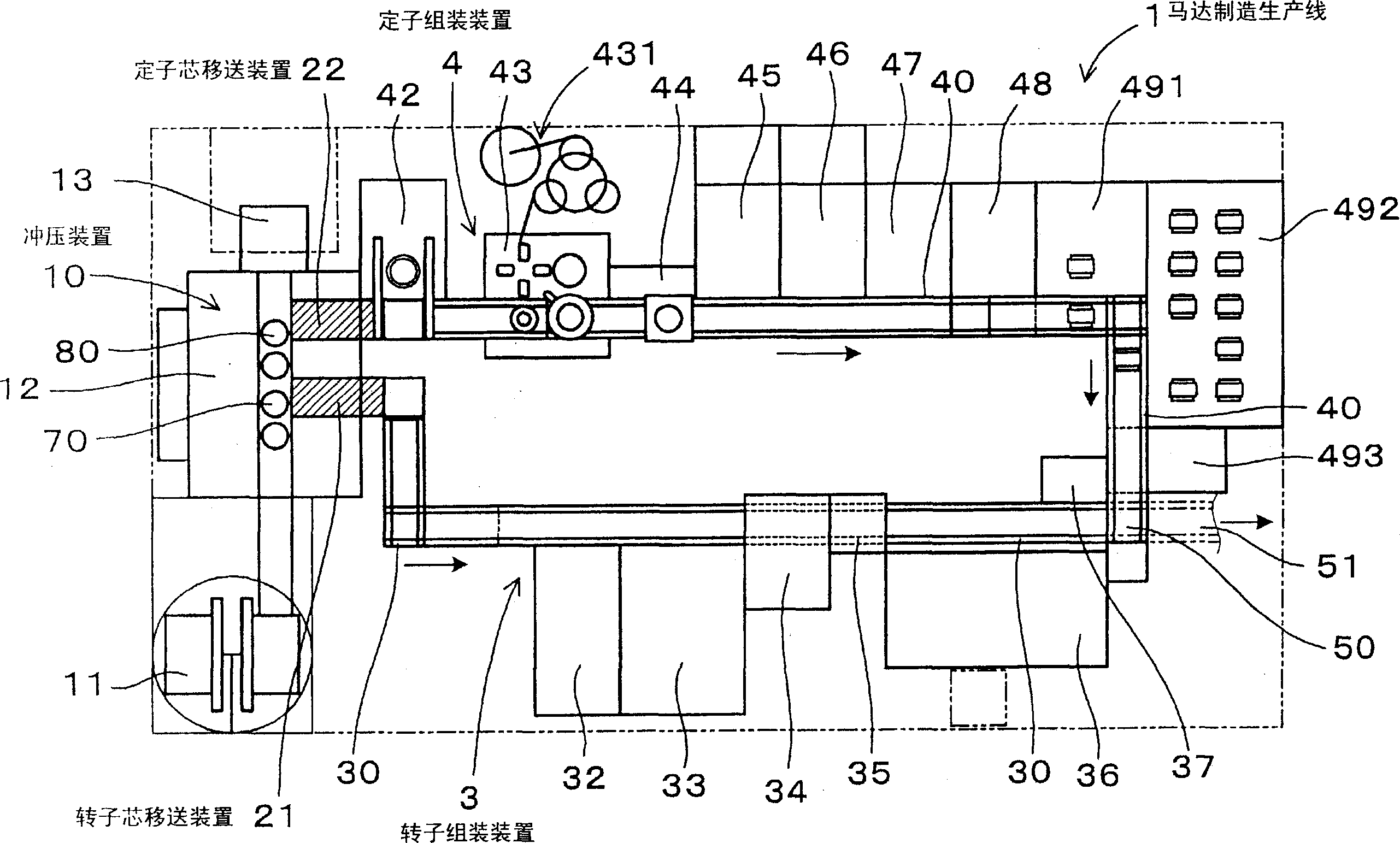

[0052] use Figure 1 to Figure 8 A motor manufacturing line related to an embodiment of the present invention will be described.

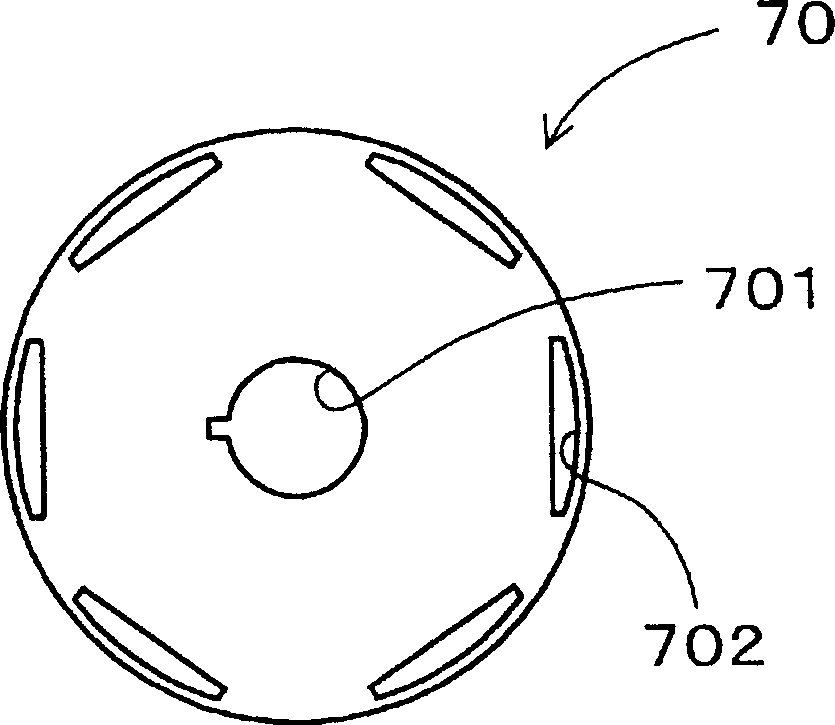

[0053] The motor manufacturing production line 1 of this example is as figure 1 Shown is a motor manufacturing line that simultaneously manufactures the rotor 7 ( FIG. 4 ) and the stator 8 ( FIG. 5 ) constituting the motor in parallel.

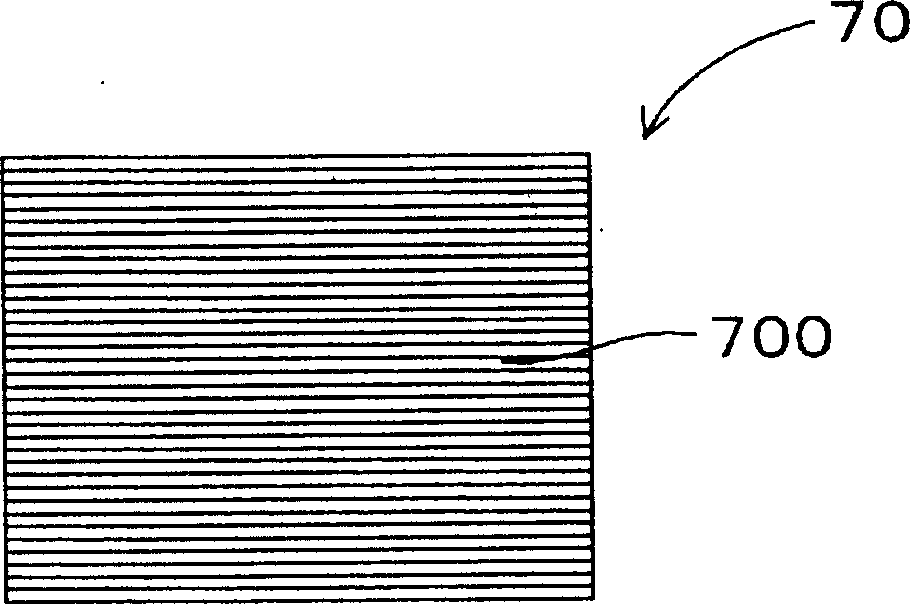

[0054] As shown in the figure, the motor manufacturing line 1 has a press device 10 that performs multiple presses while conveying a long steel plate, and laminates a plurality of steel plates to form a rotor core 70 ( FIG. 2 ) and a stator core 80 ( FIG. 3 ). The rotor assembly device 3 performs a plurality of manufacturing steps on the rotor core 70 to assemble the rotor 7 , and the stator assembly device 4 performs a plurality of manufacturing steps on the stator core 80 to assemble the stator 8 .

[0055] Between the rotor assembly device 3 and the press device 10 is provided a rotor core transfer device 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com