Method for producing mixed electrolyzed water

A manufacturing method, electrolyzed water technology, applied in the direction of water treatment parameter control, chemical instruments and methods, electrochemical water/sewage treatment, etc., can solve the problems of inability to electrolyze additives, reduction ability reduction, use, etc., and achieve high safety , Improve the disproportionation ability, the effect of simple manufacturing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] A method for preparing such an aqueous organic electrolyte solution 4 includes a method of dissolving an organic electrolyte such as ascorbic acid in purified water (pure water) such as distilled water or deionized water within the above-mentioned concentration range.

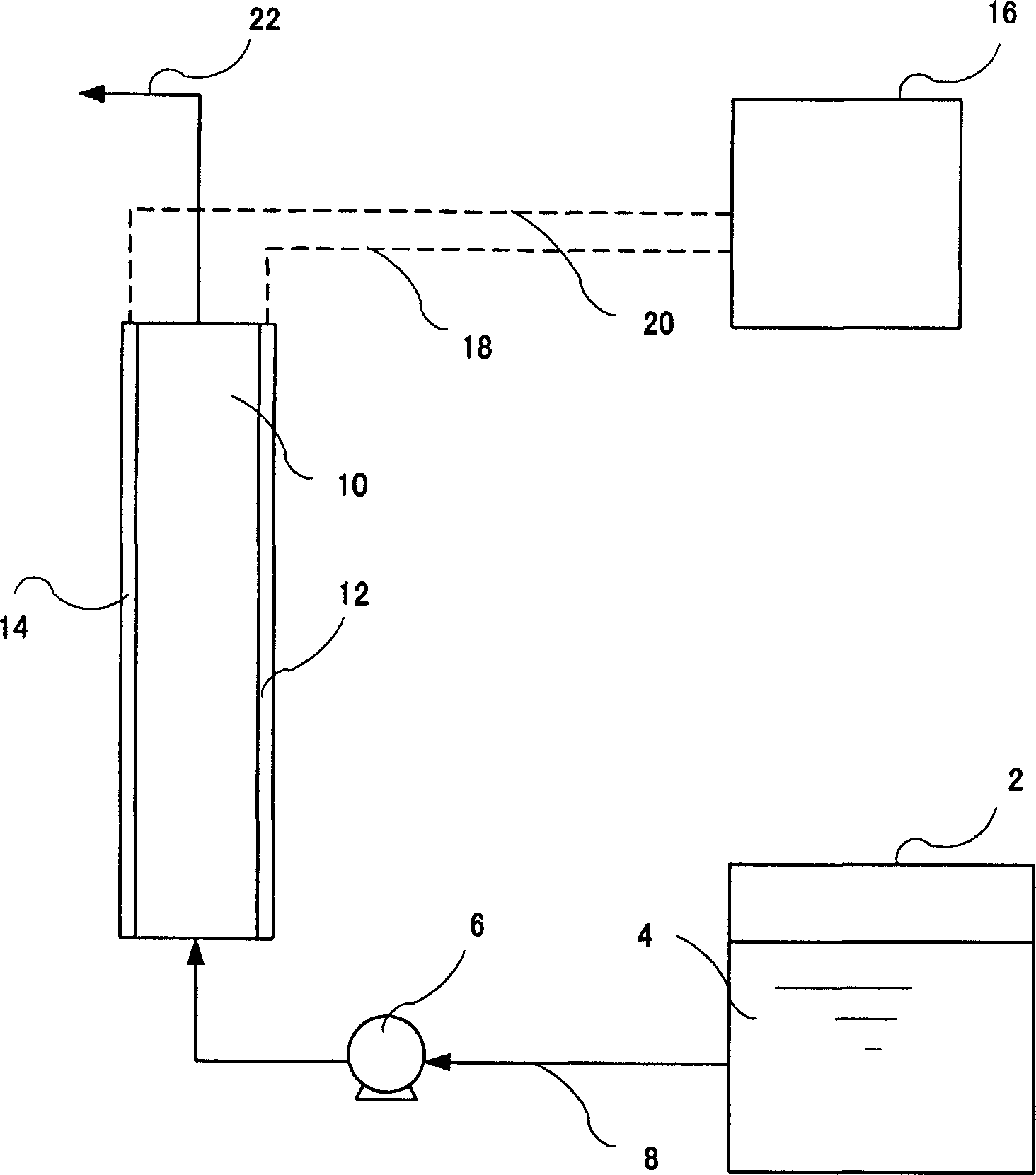

[0067] 6 is a pump attached to the organic electrolyte aqueous solution supply pipe 8 , and by operating the pump 6 , the organic electrolyte aqueous solution 4 is sent to the diaphragmless electrolytic cell 10 through the supply pipe 8 .

[0068] The aforementioned diaphragmless electrolytic cell 10 has a pair of electrodes 12, 14 opposed to each other at a predetermined interval inside. The distance between the aforementioned pair of electrodes 12 and 14 is 2 mm or less, preferably 1.5-0.05 mm, more preferably 1.0-0.1 mm. When the distance between the electrodes exceeds 2 mm, the anode-side electrolyzed water generated by electrolysis and the cathode-side electrolyzed water are not sufficiently mixed, ...

Embodiment 1

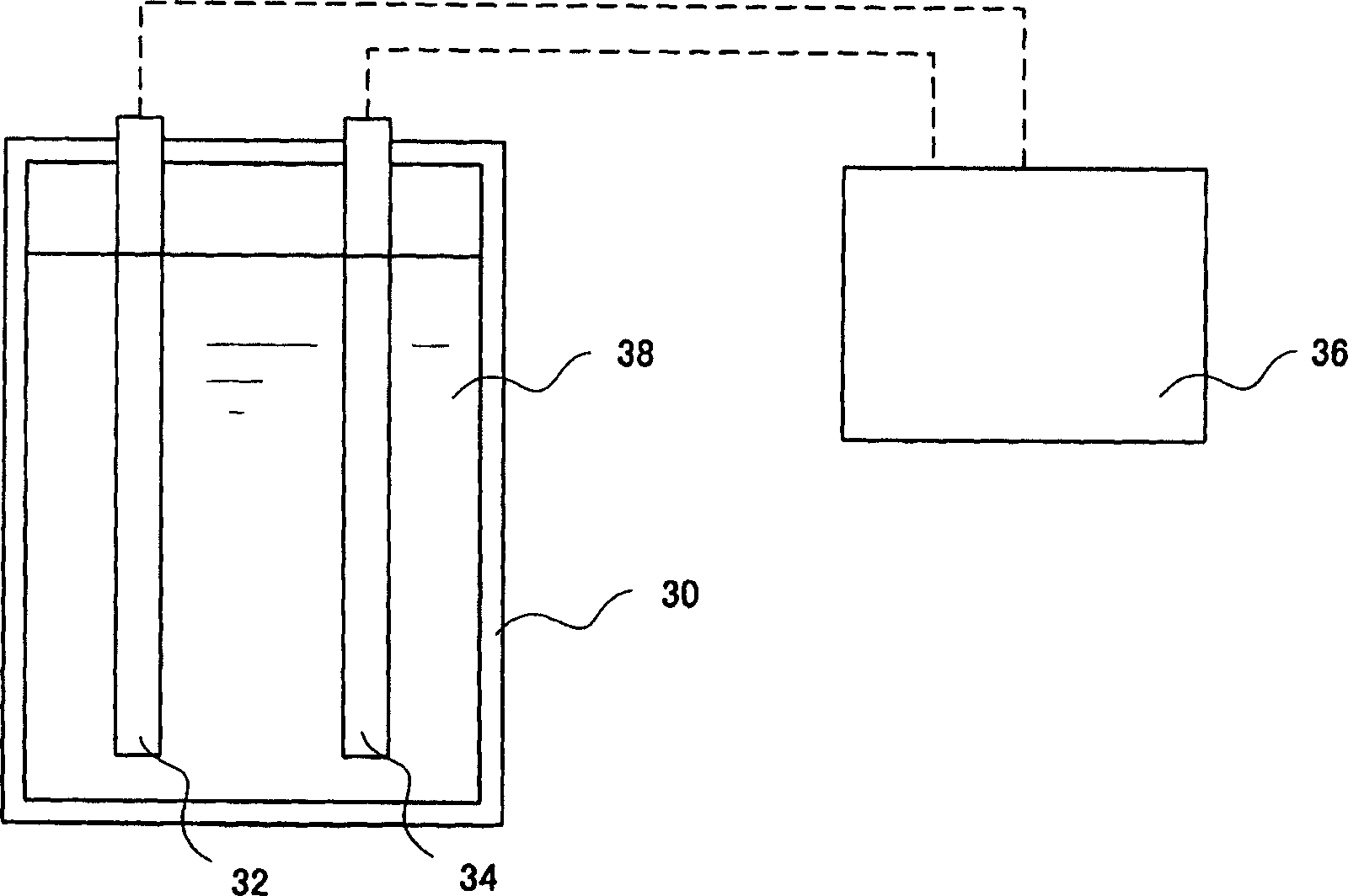

[0080] use figure 2 The electrolysis device shown in , electrolyzes electrolyzed raw water containing ascorbic acid (AsA).

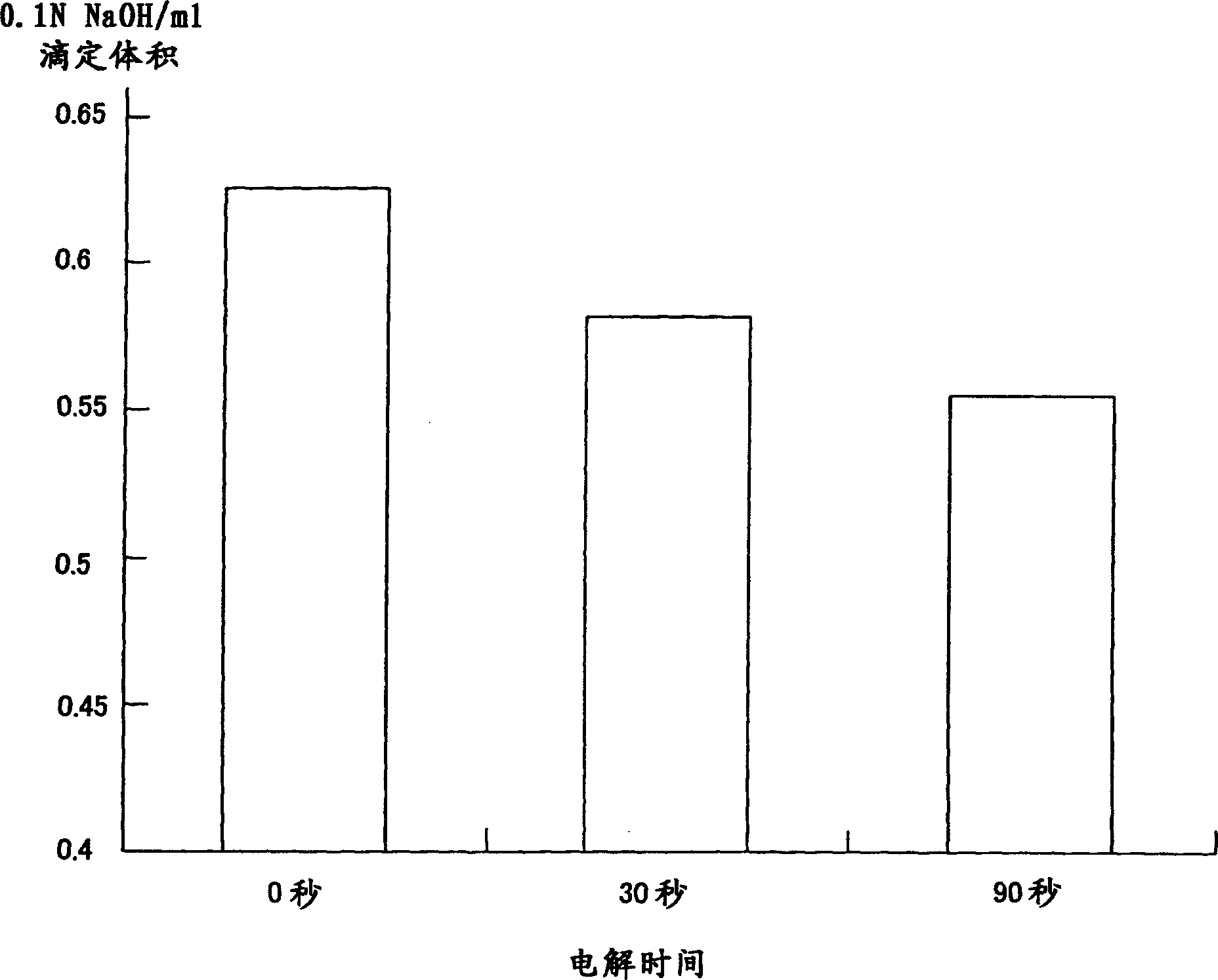

[0081]A pair of 10 x 10 cm titanium coated with platinum electrodes was installed in the electrolytic cell. The distance between electrodes was 2mm. The electrolytic cell is a rectangle with a length of 11 cm, a width of 5 cm, and a height of 12 cm. An AsA aqueous solution with a concentration of 30 mM was prepared, and 660 ml of the AsA aqueous solution was filled in the aforementioned electrolytic cell. While stirring the AsA aqueous solution, conduct electrolysis by passing a current of 0.25A to the two electrodes. Electrolysis was performed by changing the polarity every 30 seconds from the start of electrolysis. Table 1 shows the pH, oxidation-reduction potential (ORP), dissolved oxygen (DO), and electrical conductivity (EC) of the mixed electrolyzed water produced by electrolysis. In addition, the mixed electrolyzed water produced by electrol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap