Multiphase motor voltage control for phase windings of different wire gauges and winding turns

A multi-phase motor, motor control technology, applied in different voltage fields

- Summary

- Abstract

- Description

- Claims

- Application Information

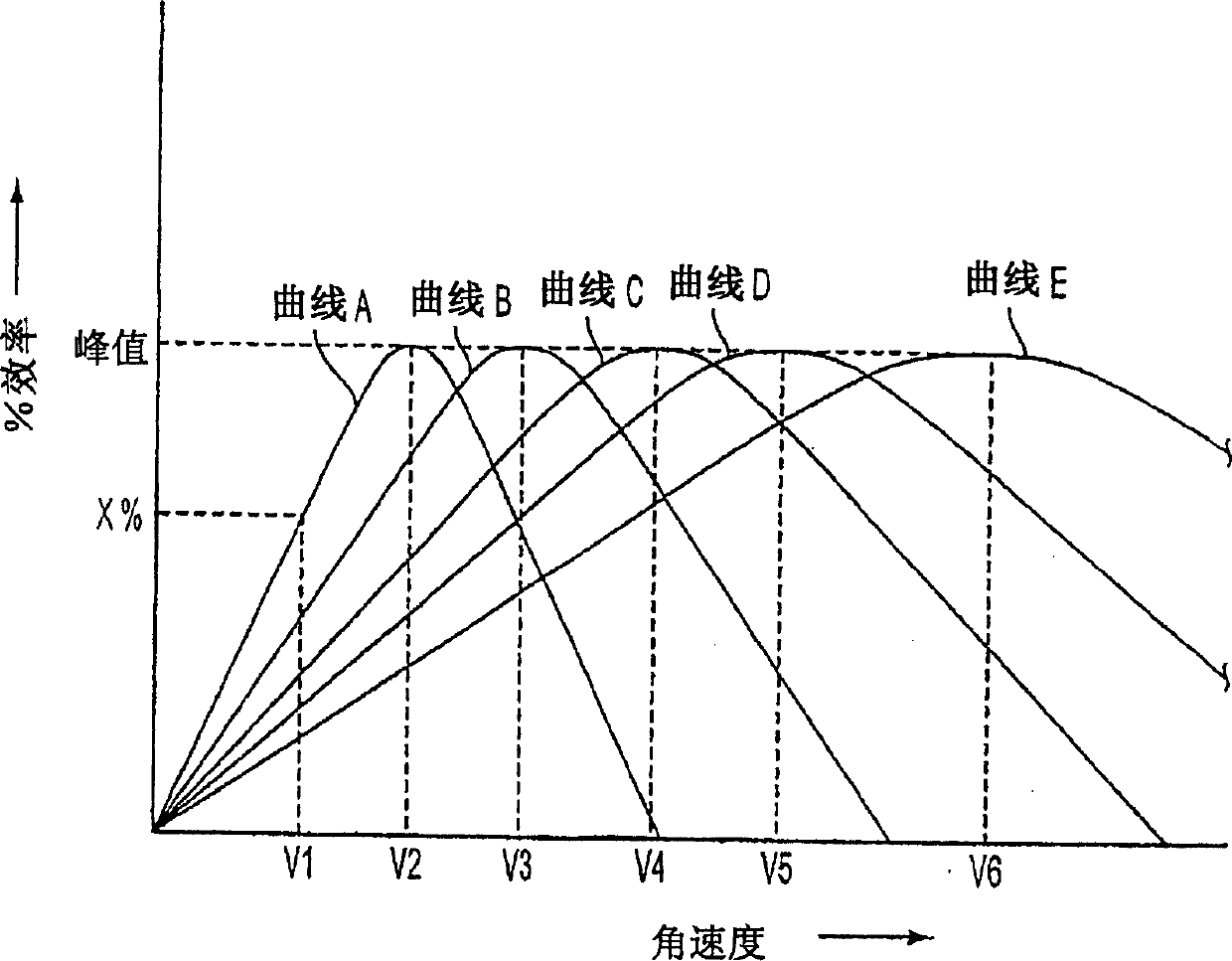

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

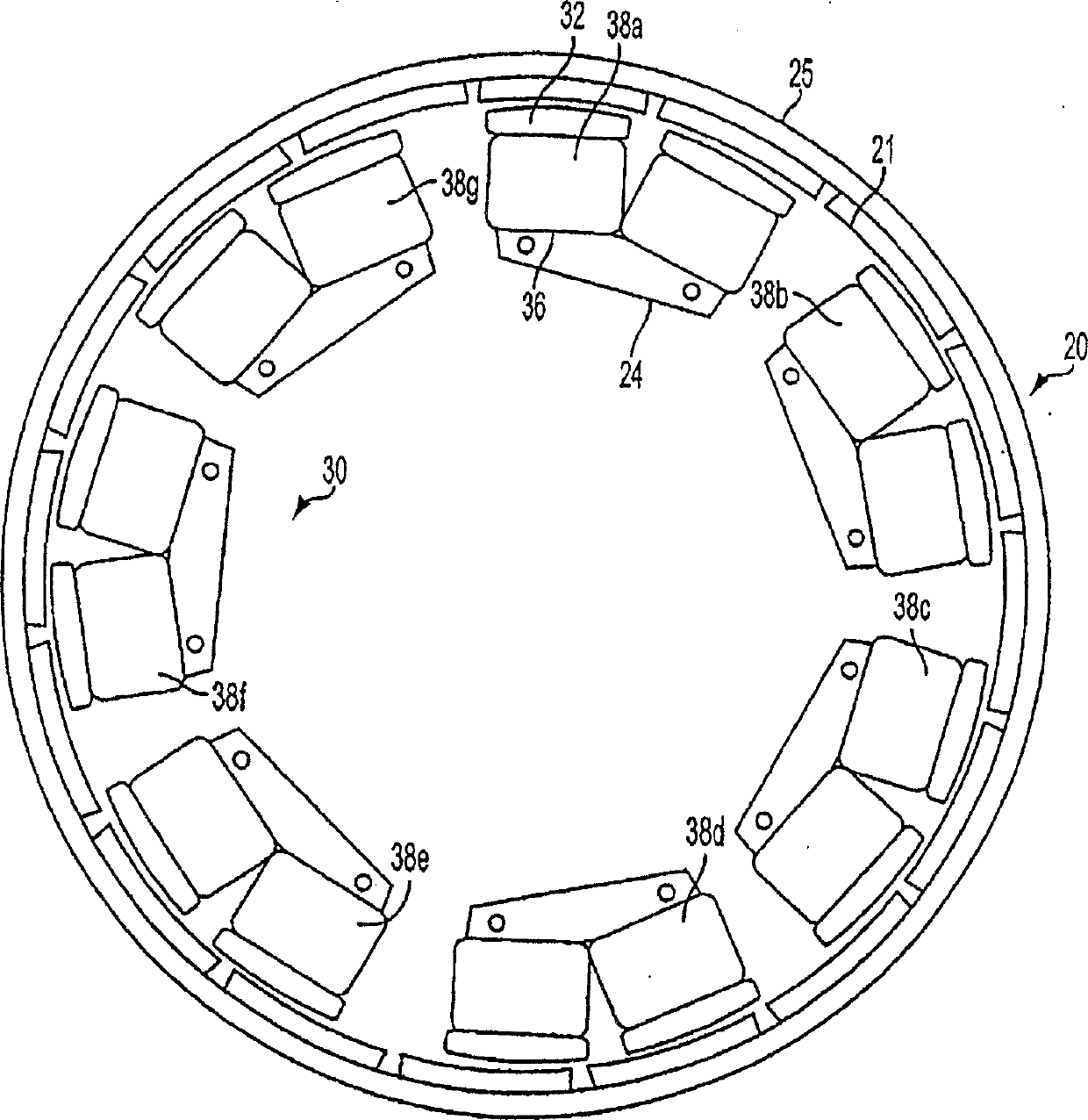

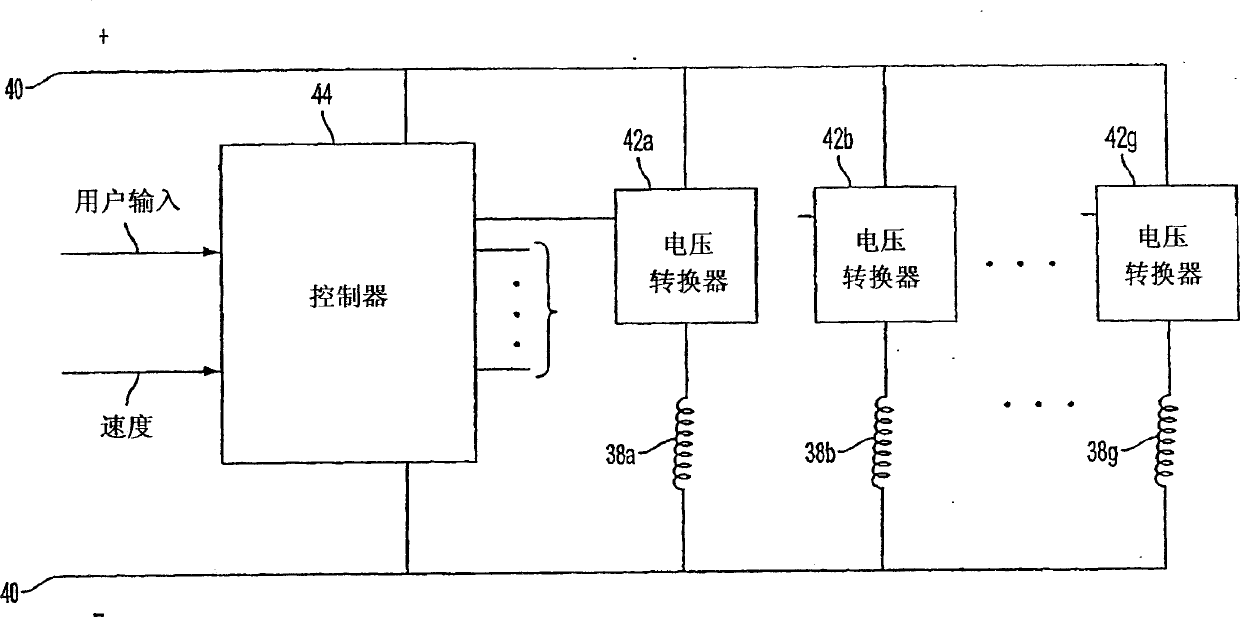

[0029] Figure 2 is a schematic structure of rotor and stator elements used in the present invention. The motors listed herein are described in more detail with reference to the aforementioned copending Maslov et al. application 09 / 826422. The rotor member 20 is an annular structure with permanent magnets 21 spaced apart from each other and distributed generally uniformly along the circumferential support plate 25 . The permanent magnets are rotor poles whose magnetic polarities alternate along the inner circumference of the ring hole. The rotor surrounds the stator member 30, the rotor and stator member being spaced apart by an annular radial air gap. The stator 30 includes a plurality of electromagnet core segments of uniform structure, which are evenly distributed along the air gap.

[0030] The stator comprises seven core segments, each formed as a common U-shaped magnetic structure 36 comprising two poles having a surface 32 facing the air gap. Windings 38 are wound aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com