Resonance drive actuator

一种致动器、电磁驱动的技术,应用在电气元件、机电装置等方向,达到容易共振、减小长度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

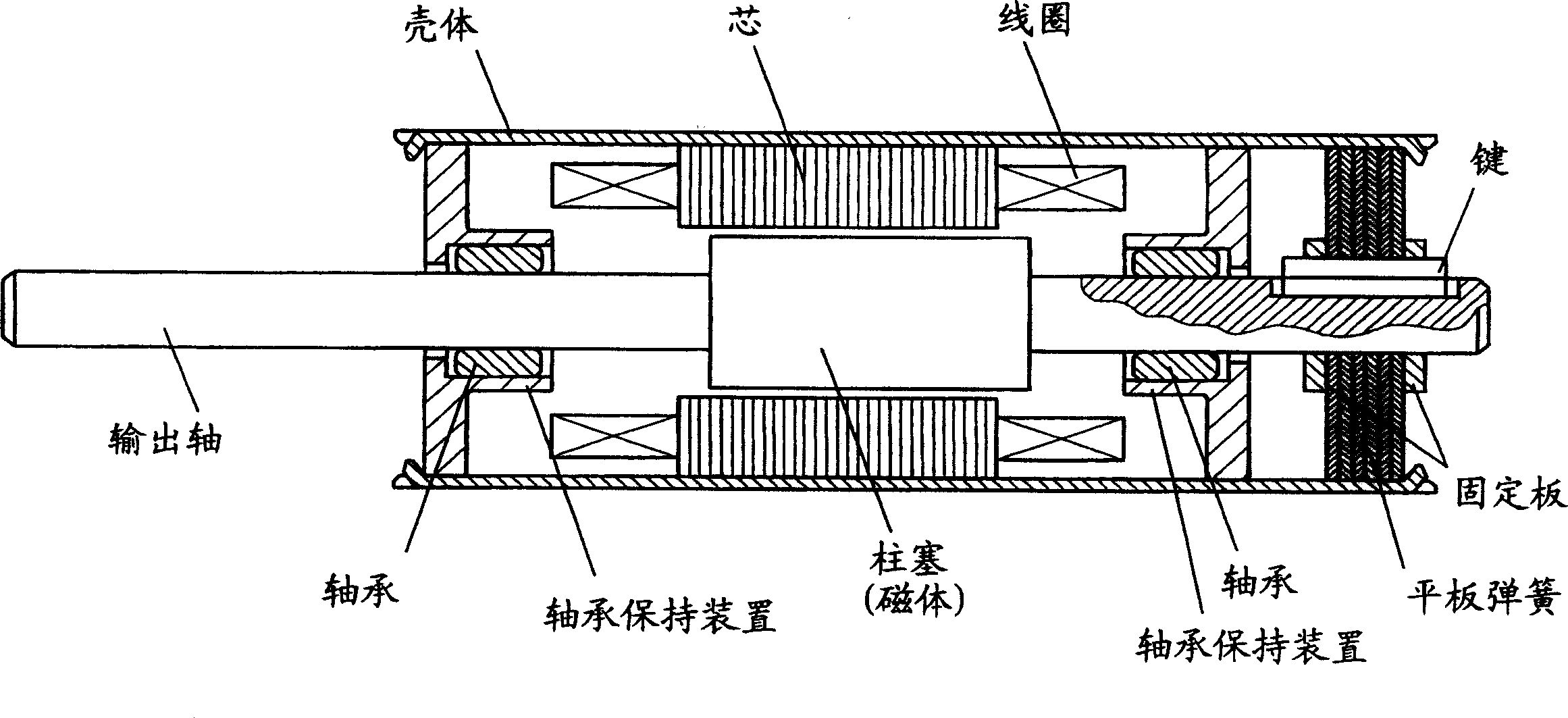

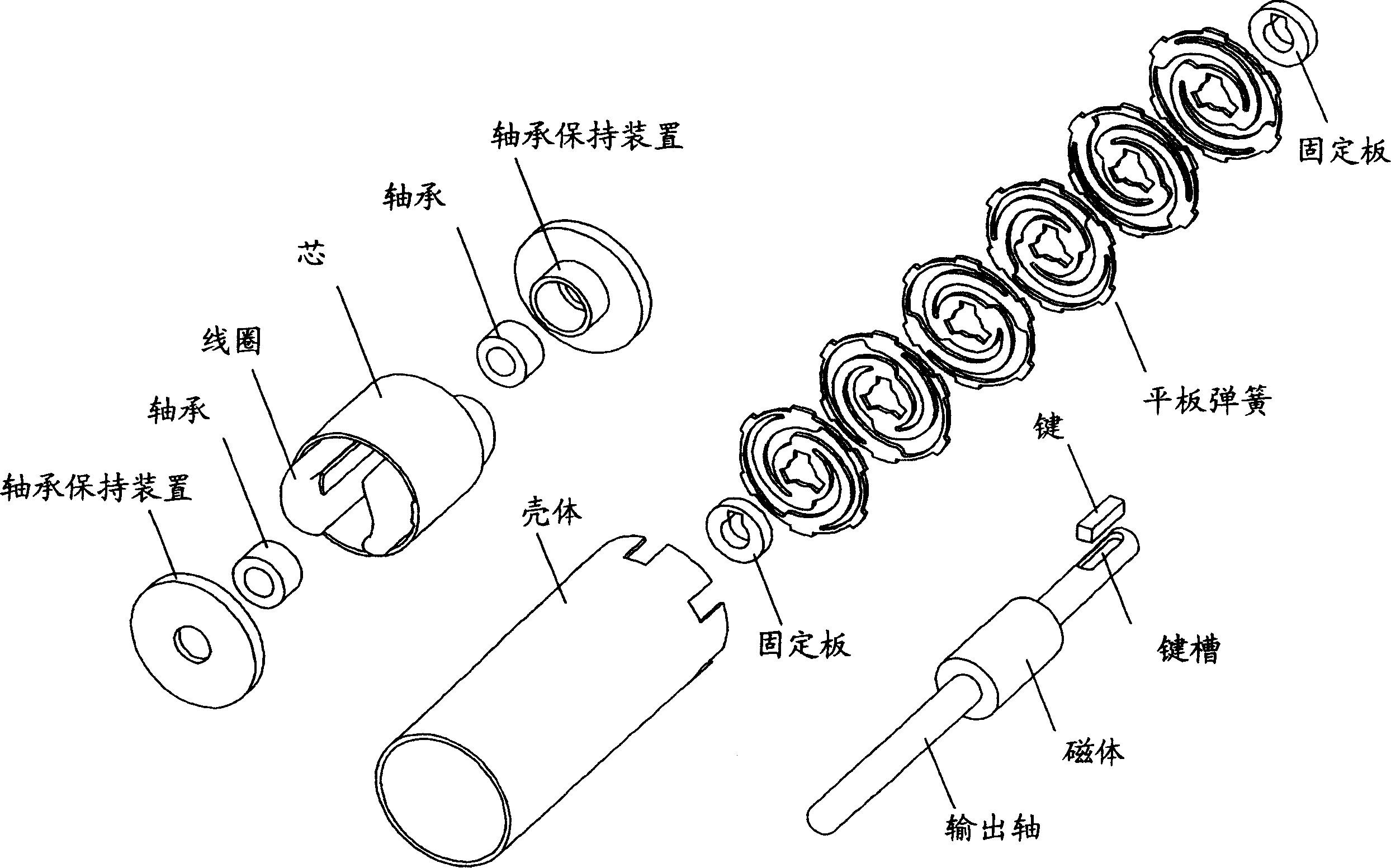

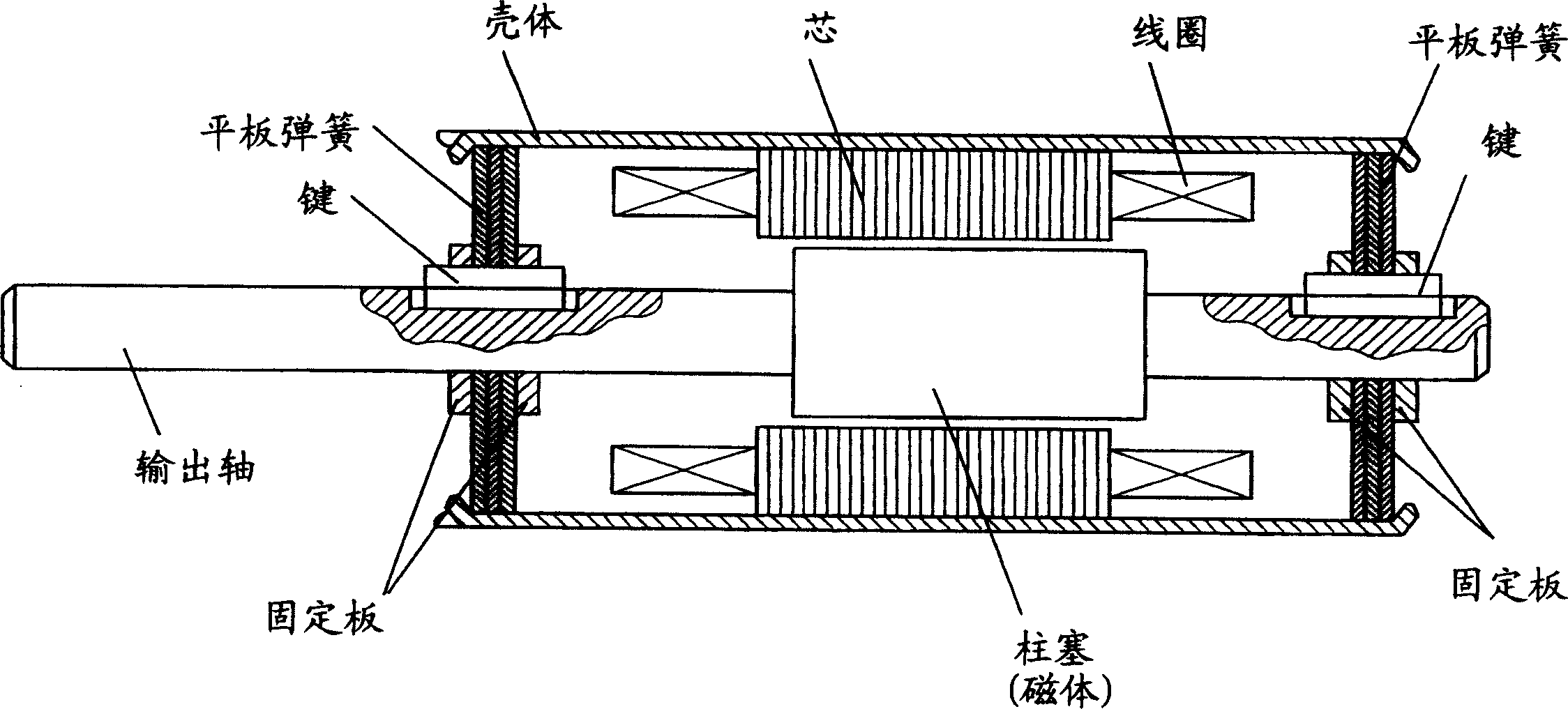

[0027] Embodiments of the present invention will be described in detail below with reference to the drawings. figure 1 is a sectional view showing a first embodiment of the actuator according to the invention. figure 2 for figure 1 An exploded perspective view of the actuator. as in figure 1 and 2 As shown in , a movable section of the actuator includes an output shaft that outputs a driving force and a cylindrical plunger fixed to the output shaft, the plunger is made of a magnet to move along the The magnets are magnetized in a circumferentially spaced manner. A load (not shown) is connected to one end of the output shaft, and the load is resonantly driven at an axial resonant frequency and a circumferential resonant frequency, the axial resonant frequency being determined by the spring force of a spring member and a movable section The mass of , while the circular resonance frequency is determined by the spring force and the inertia of the movable section. For exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com