Injection molding machine driving device, injection device and mold clamping device

A technology of injection molding machine and driving device, applied in the field of driving device, can solve the problems of increasing the linear motor, increasing the cost of the driving device, increasing the weight of the mover, etc. Effect of Moment of Inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

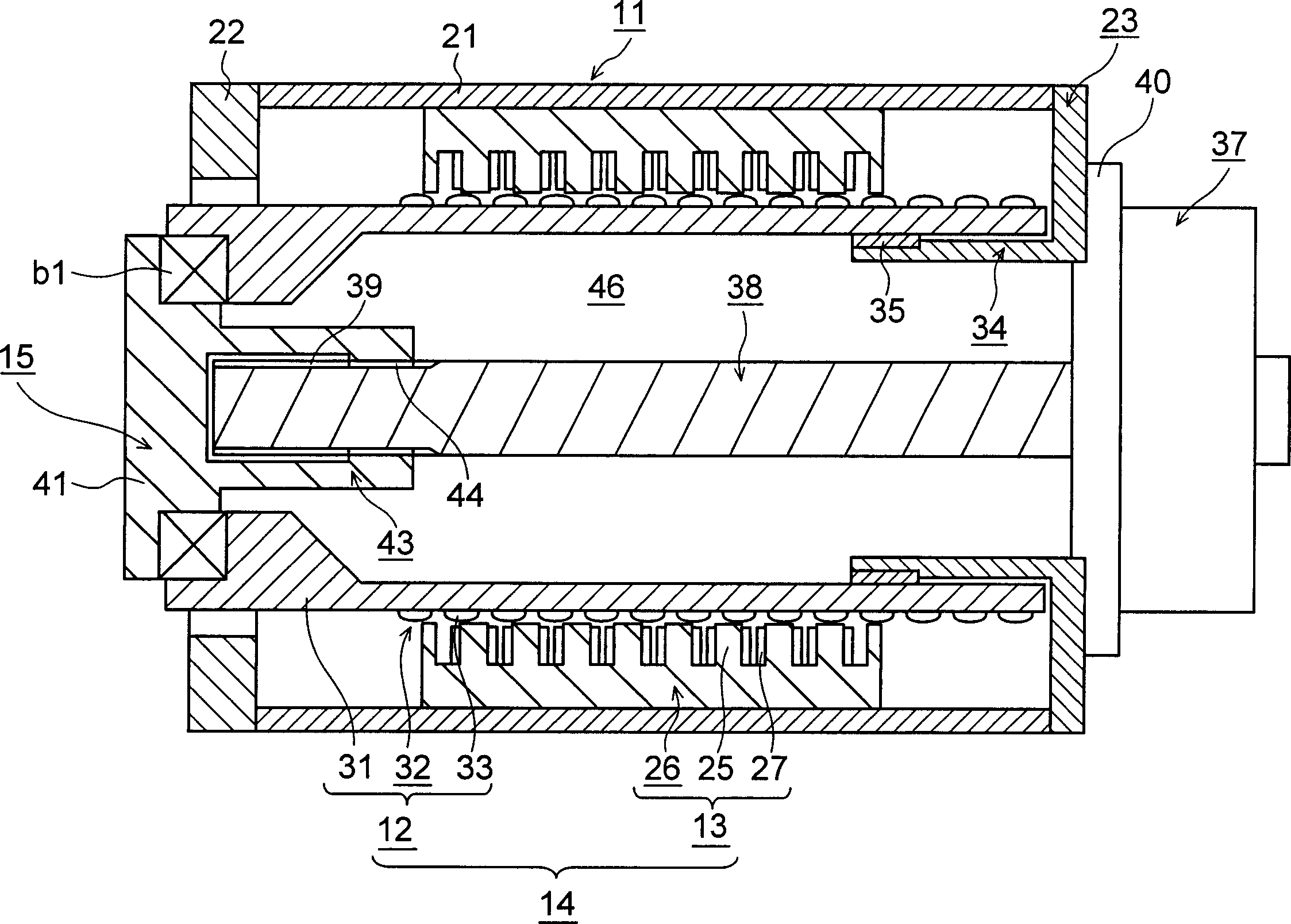

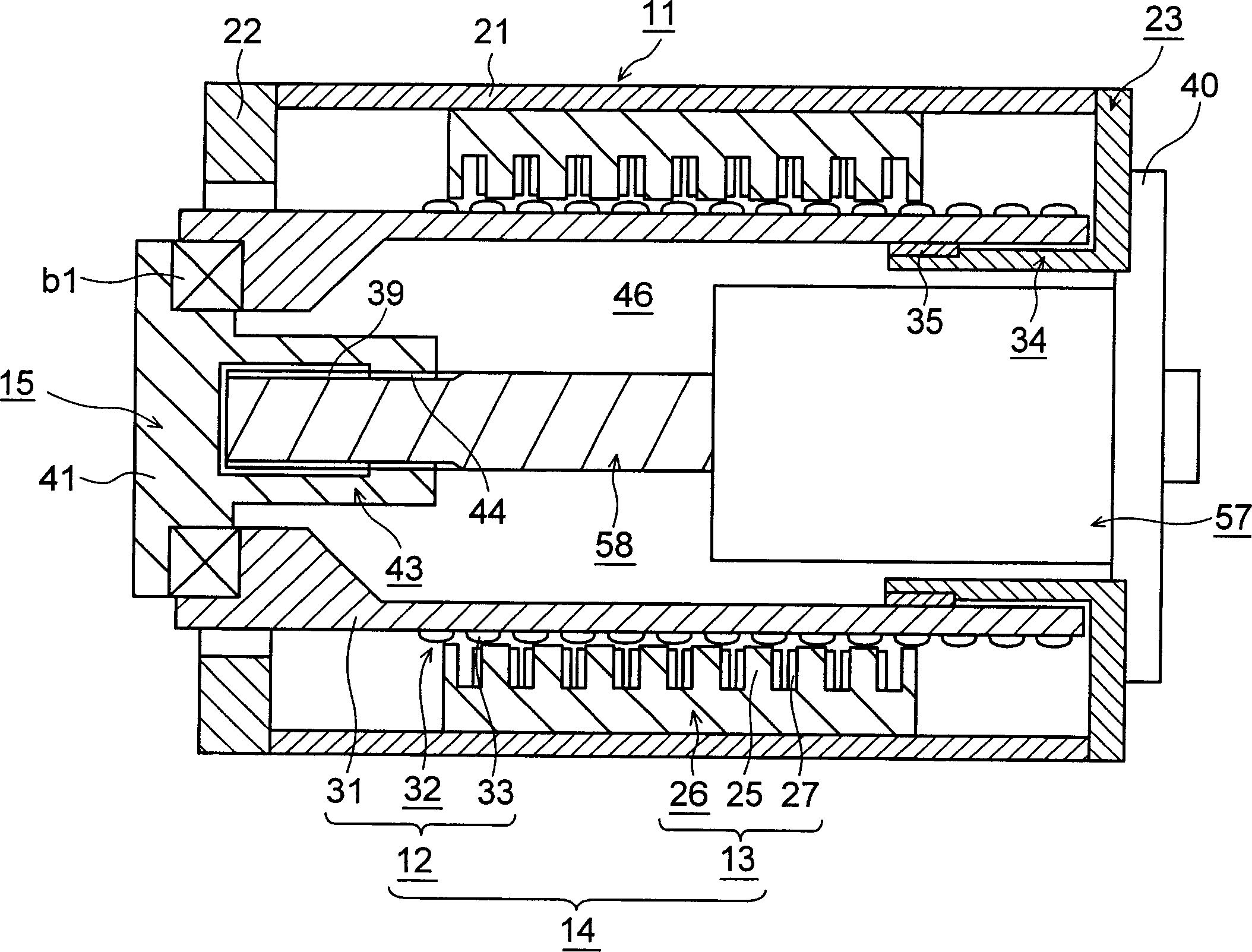

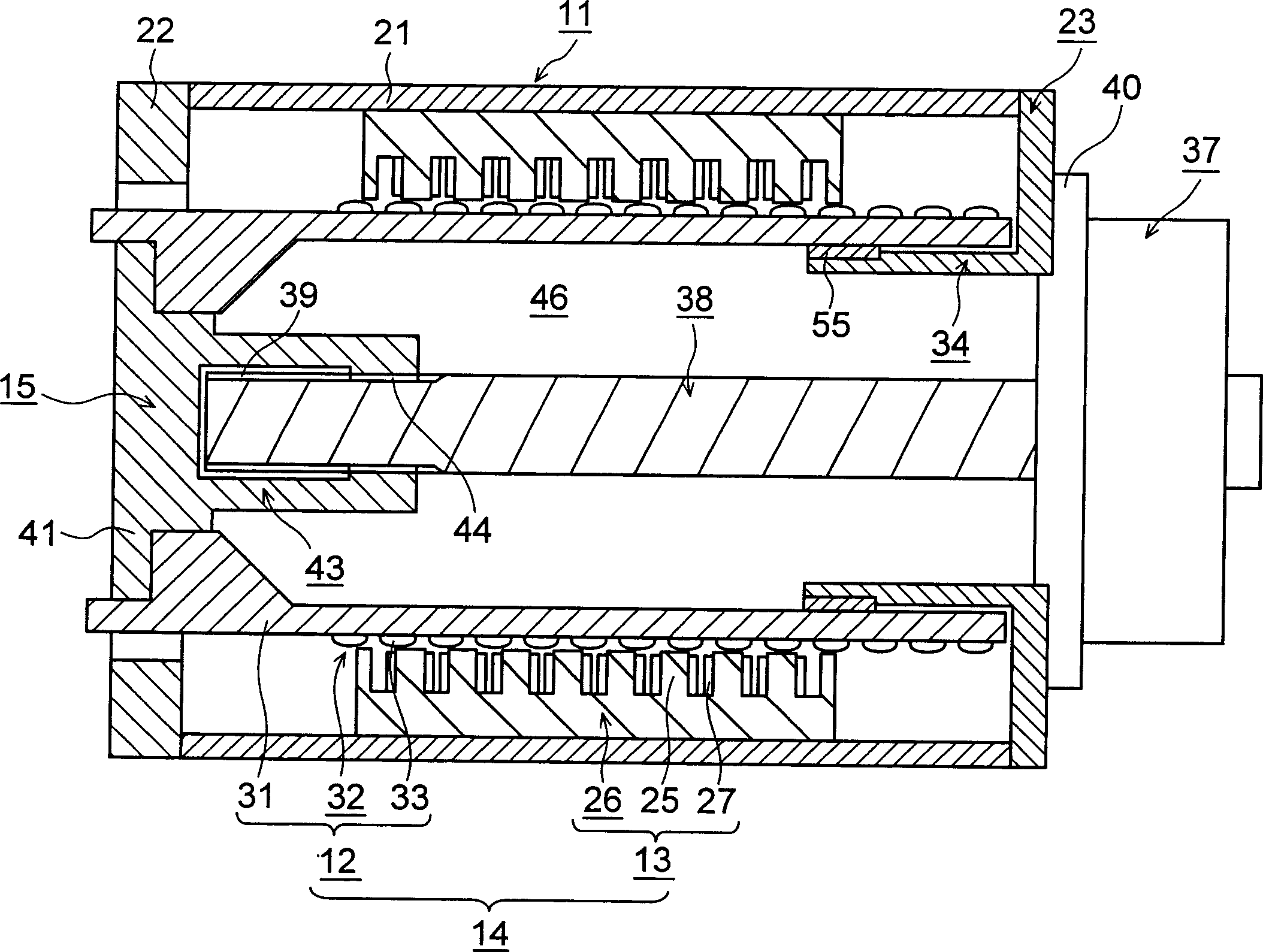

[0042] Embodiments of the present invention will be described in detail below with reference to the drawings.

[0043] Fig. 1 is a cross-sectional view of a drive device according to a first embodiment of the present invention. In addition, at this time, the drive unit installed in a molding machine as a mechanical device, such as an injection molding machine, will be described.

[0044]In the figure, 11 is a cylindrical frame, 12 is a cylindrical mover installed freely in the axial direction in the frame 11 (moving in the left and right direction in the figure), and 13 is attached to the frame 11. The cylindrical stator 15 on the inner peripheral surface is a driven body that is rotatable relative to the above-mentioned mover 12 through the bearing b1 and is freely arranged to advance and retreat together with the above-mentioned mover 12. In front of the driven body 15 (Fig. Middle left) is provided with a moving body not shown in the figure so that it can rotate freely and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com