Meridian aircraft tyre

An aviation tire and radial technology, which is applied to tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve the problems of easy peeling of the end of the cord and the rubber, damage to the end of the tire belt, etc. Achieve the effect of increasing speed, inhibiting expansion growth, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

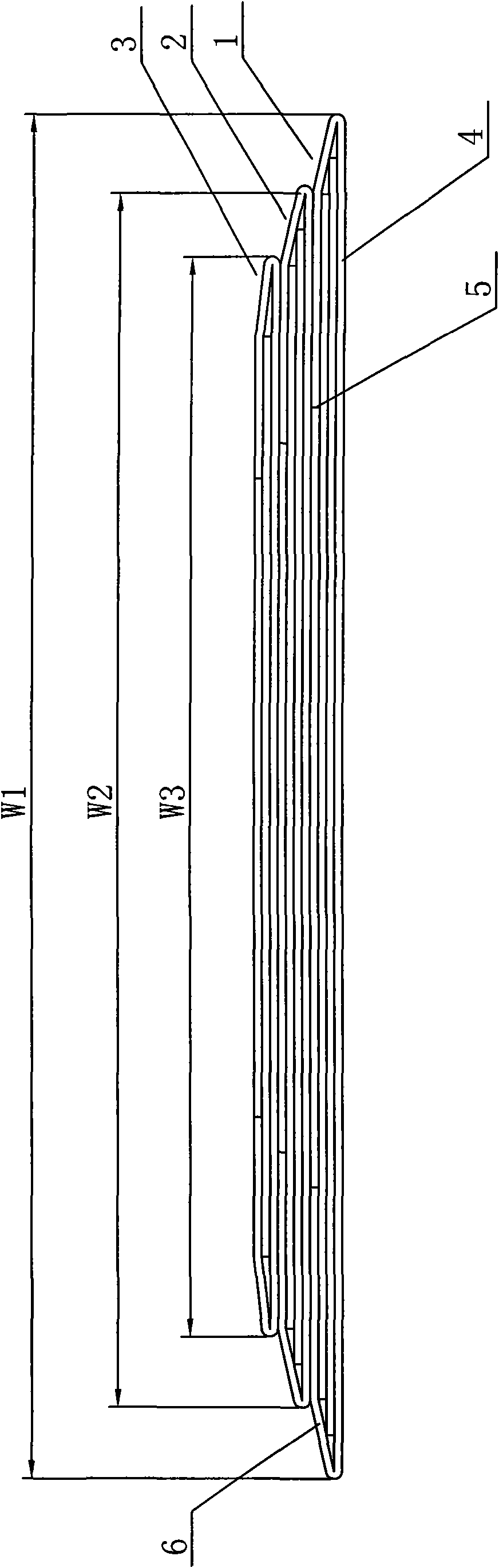

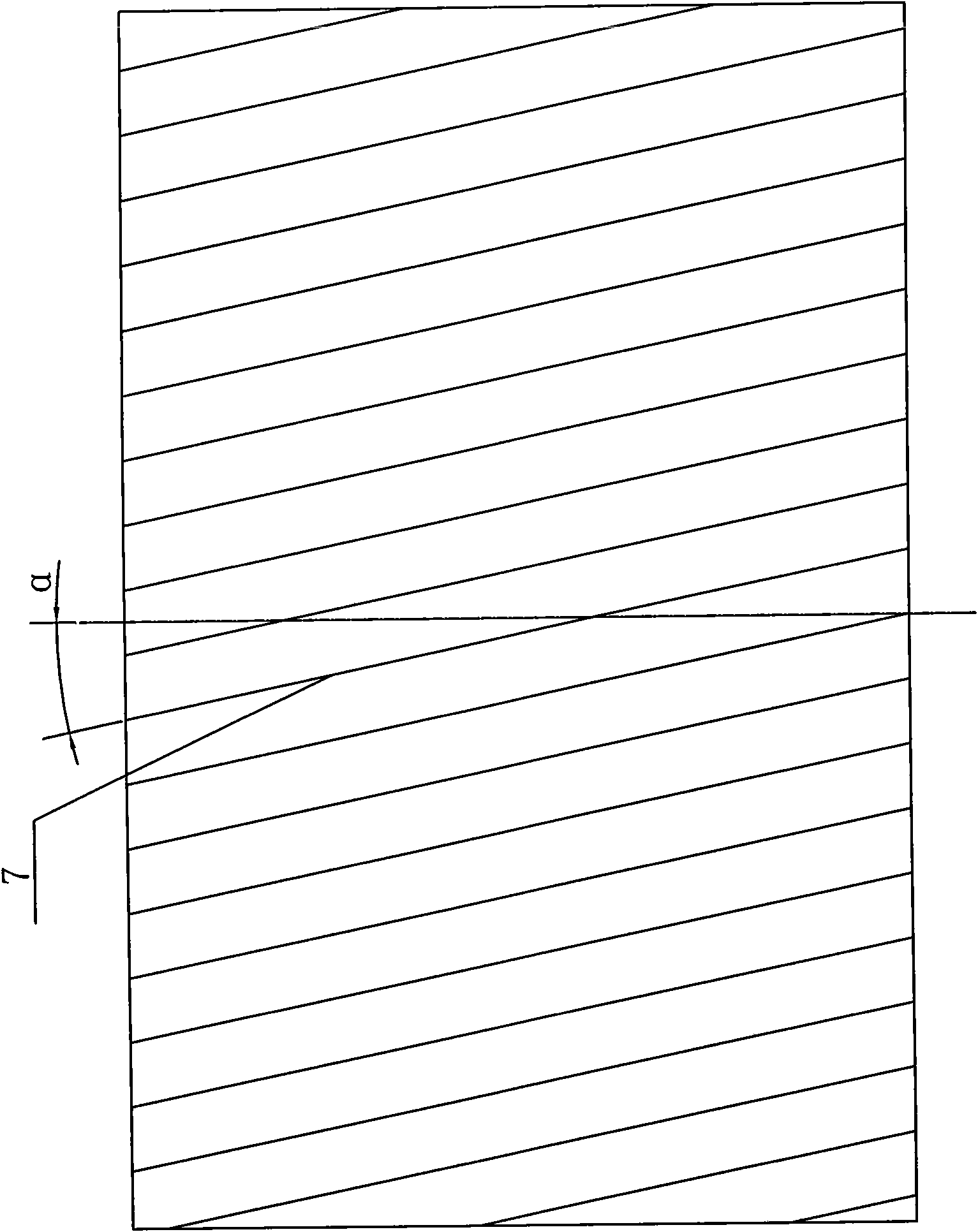

[0017] The radial aviation tire of the present invention comprises a belt layer, the belt layer is formed by laminating at least one belt layer group, the angle α between the belt layer cord 7 and the tread circumferential direction is 10°-20°, Preferably 12°~17°; wherein,

[0018] The belt layer group is formed by laminating three or four layers of belt ply layers 4. In the same group of belt layer groups, the two ends of the lowermost belt layer layer 4 are folded upward to form curling 6, and the curling 6 Wrap the two ends of the other belt plies 4 in the belt group except the first belt ply 4, and the ends of the curling 6 are connected with the two ends of the first belt ply 4 respectively. Contiguously, the interface 5 is located within the coverage of the belt ply 4 or the crown layer above the first belt ply 4 .

[0019] In two adjacent belt plies in the same belt group, the width of the upper belt ply 4 is narrower than that of the lower belt ply 4; in two adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com