Directly controlled pressure control valve

A relief valve, direct technology, applied in the direction of fluid pressure control, non-electric variable control, control/regulation system, etc., can solve the problems of reducing the service life of DBV, unpleasant, high mechanical stress of seat piston, etc., to suppress contact vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

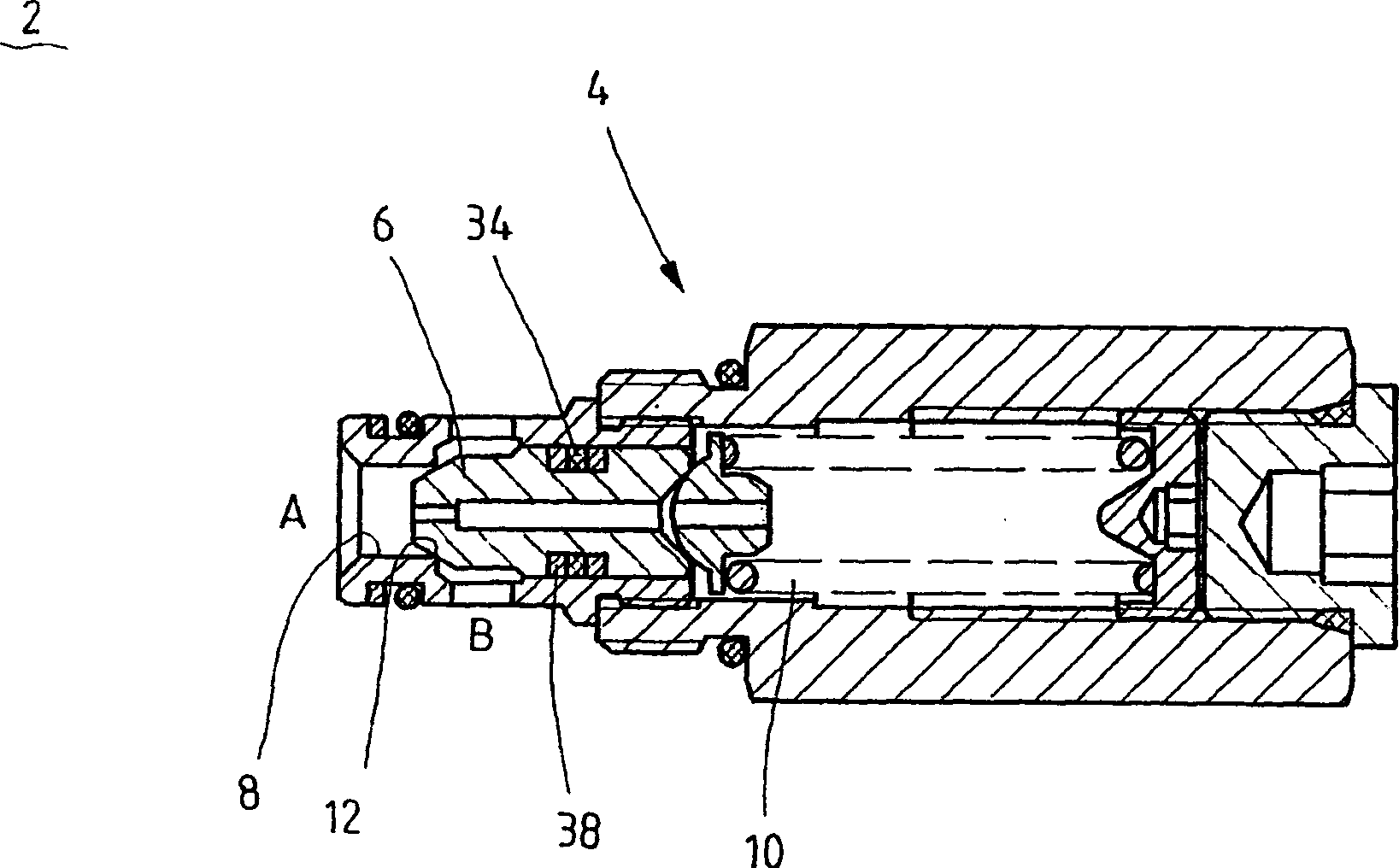

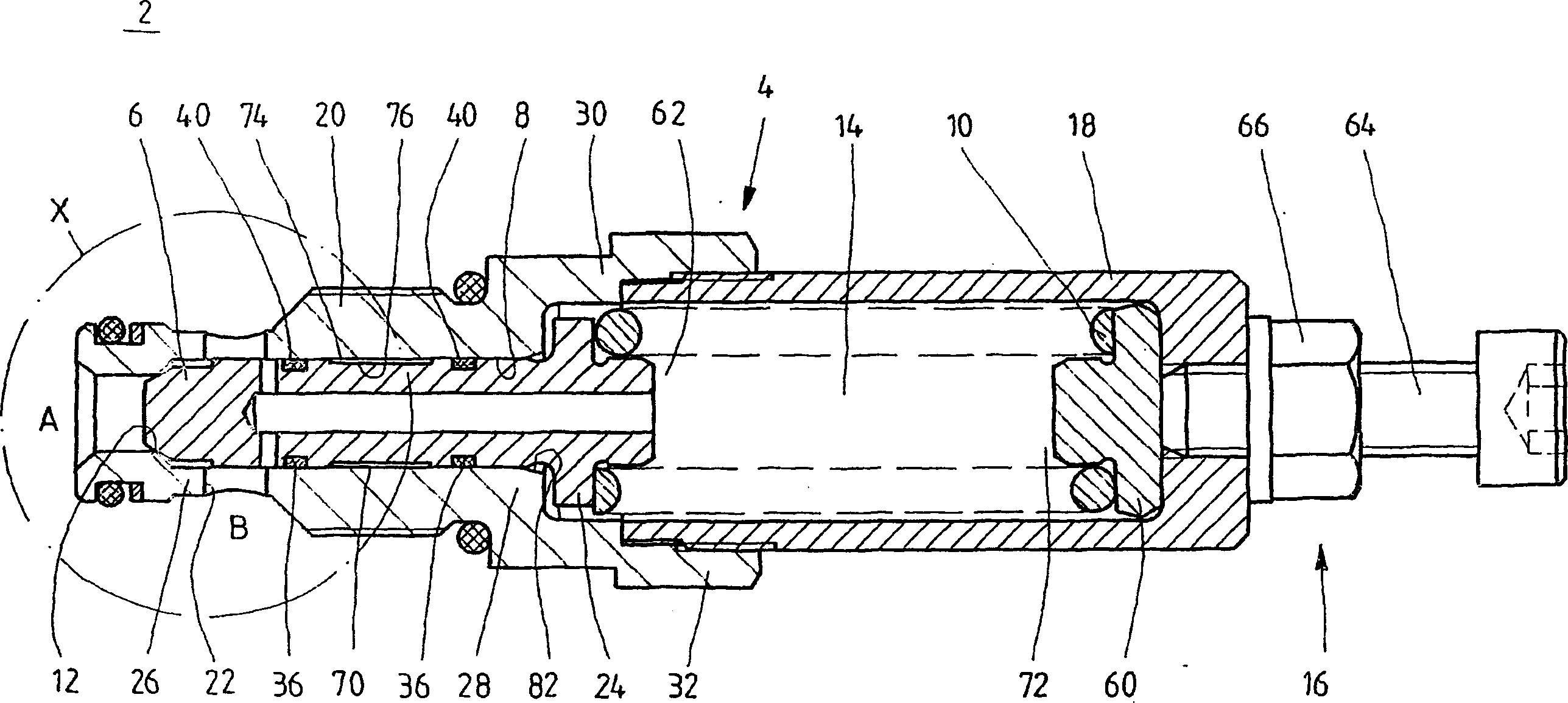

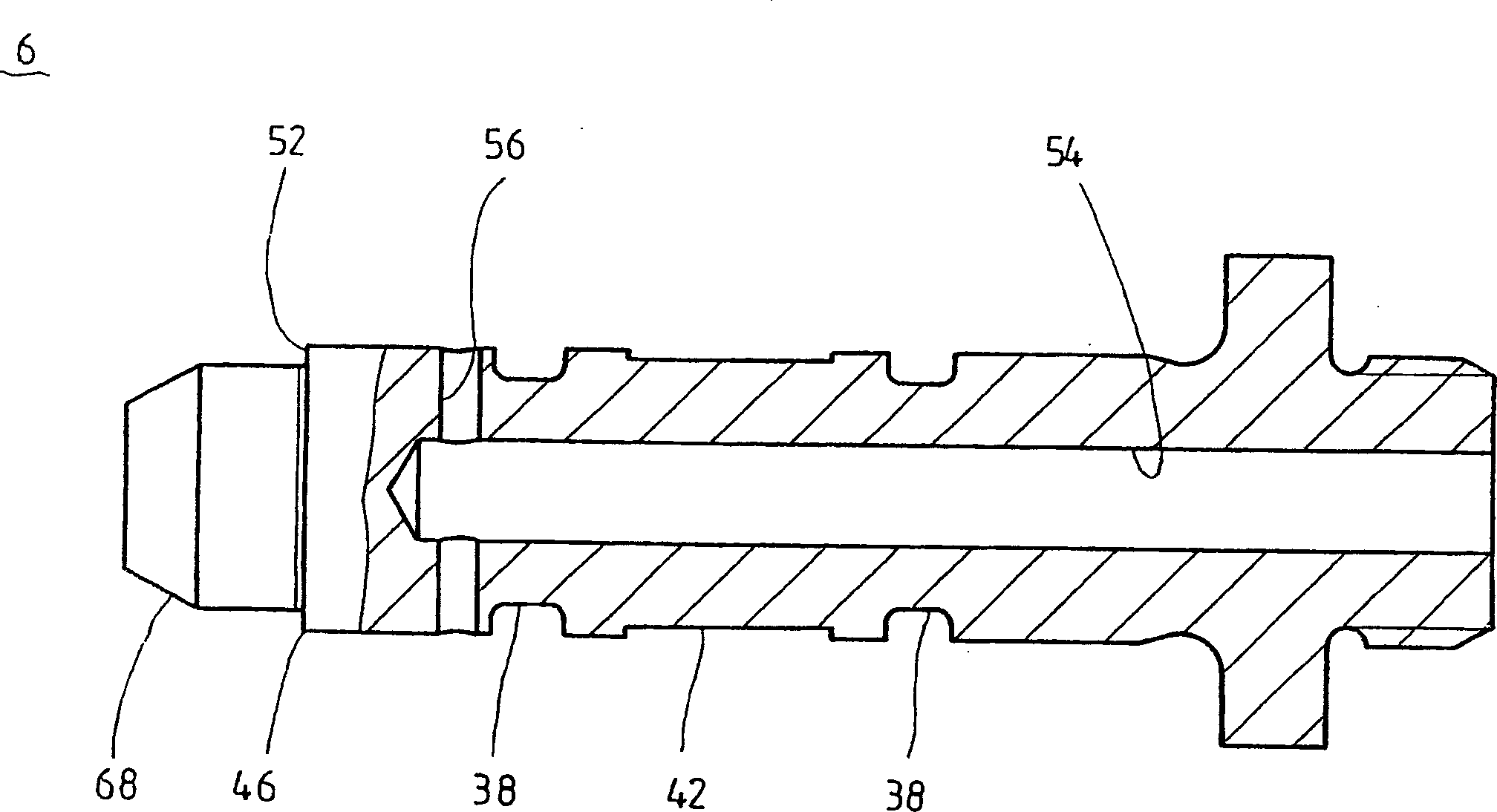

[0023] figure 2 A cutaway side view of a preferred embodiment of a directly controlled overflow valve (DBV) 2 according to the invention is shown. The DBV 2 has a multi-part valve housing 4 comprising a longitudinal bore 8 in which a seat piston 6 is slidably received. Seat piston 6 is biased by spring 10 to its rest position against valve seat 12 . The spring 10 is disposed in a spring cavity 14 and has an adjustable bias via a biasing device 16 .

[0024] The valve sleeve 4 has a spring chamber housing 18 and a seat piston housing 20 . Spring chamber housing 18 bounds spring chamber 14 for receiving spring 10 and is connected to seat piston housing 20 by threaded engagement. In the spring cavity 14 , the spring 10 is supported by the end portion 72 on the bias cover 60 of the bias device 16 . With its second end portion 62 the spring rests on the spring cover 24 of the seat piston 6 .

[0025] The biasing device 16 is arranged in the rear region of the spring chamber h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com