Linear compressor

A linear compressor, elastic sheet technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as unavoidable wear and deformation, and achieve the effect of preventing wear and deformation and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The examples shown in the drawings will now be described in detail with reference to embodiments of the invention, wherein like reference numerals refer to like elements throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

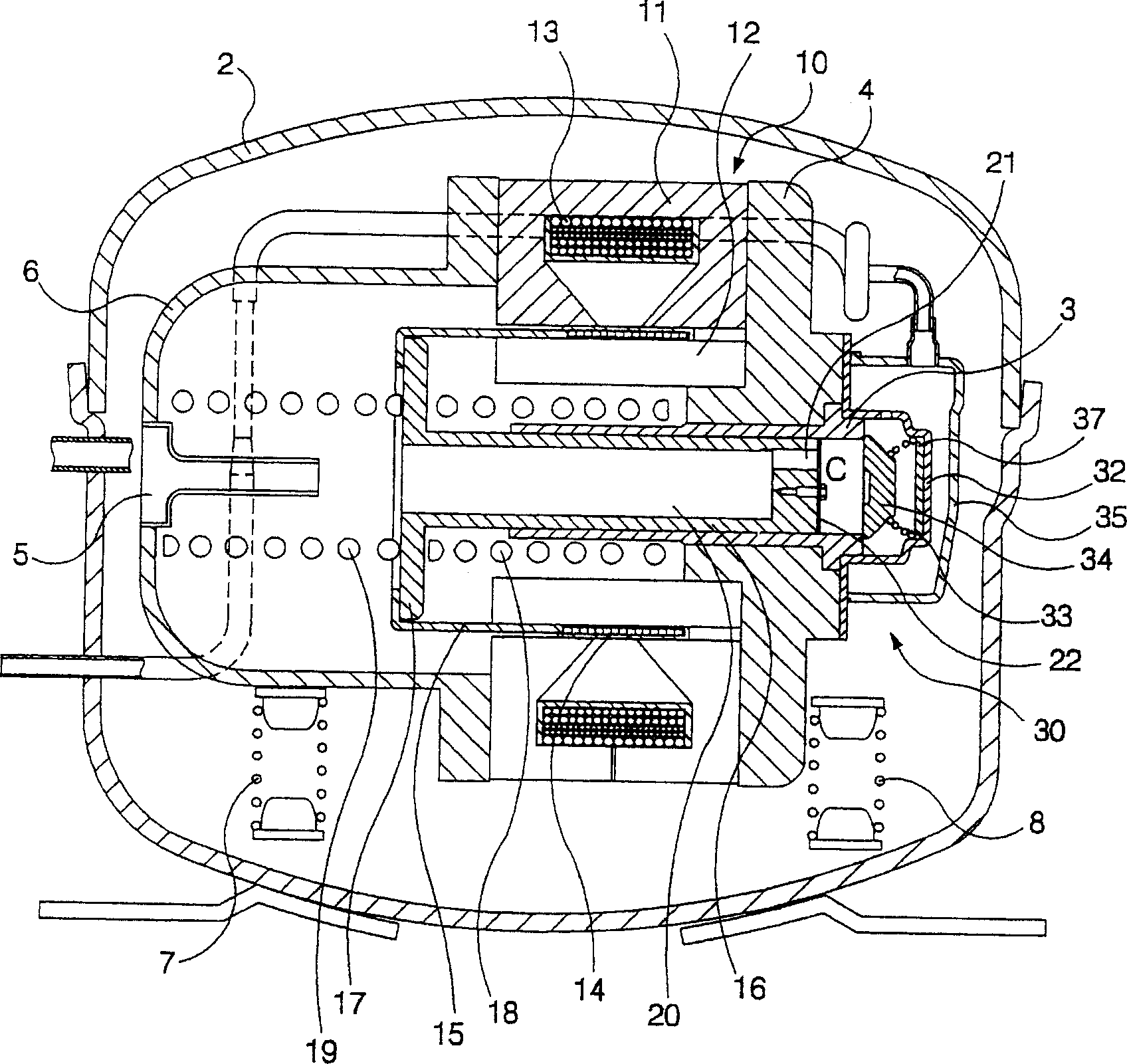

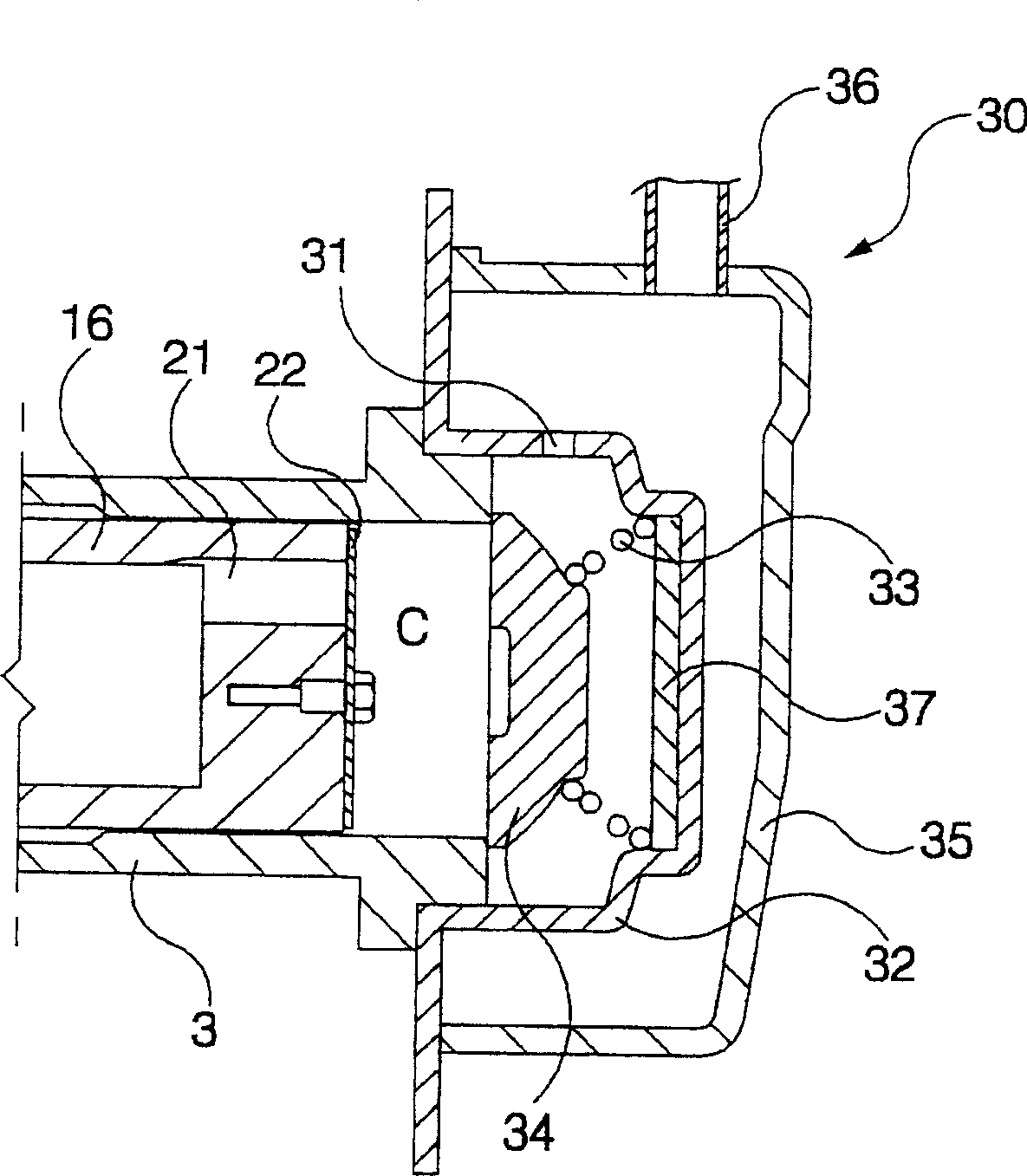

[0050] image 3 shows a linear compressor according to a first embodiment of the invention; Figure 4 The structure of the discharge part of the linear compressor according to the first embodiment of the present invention is shown.

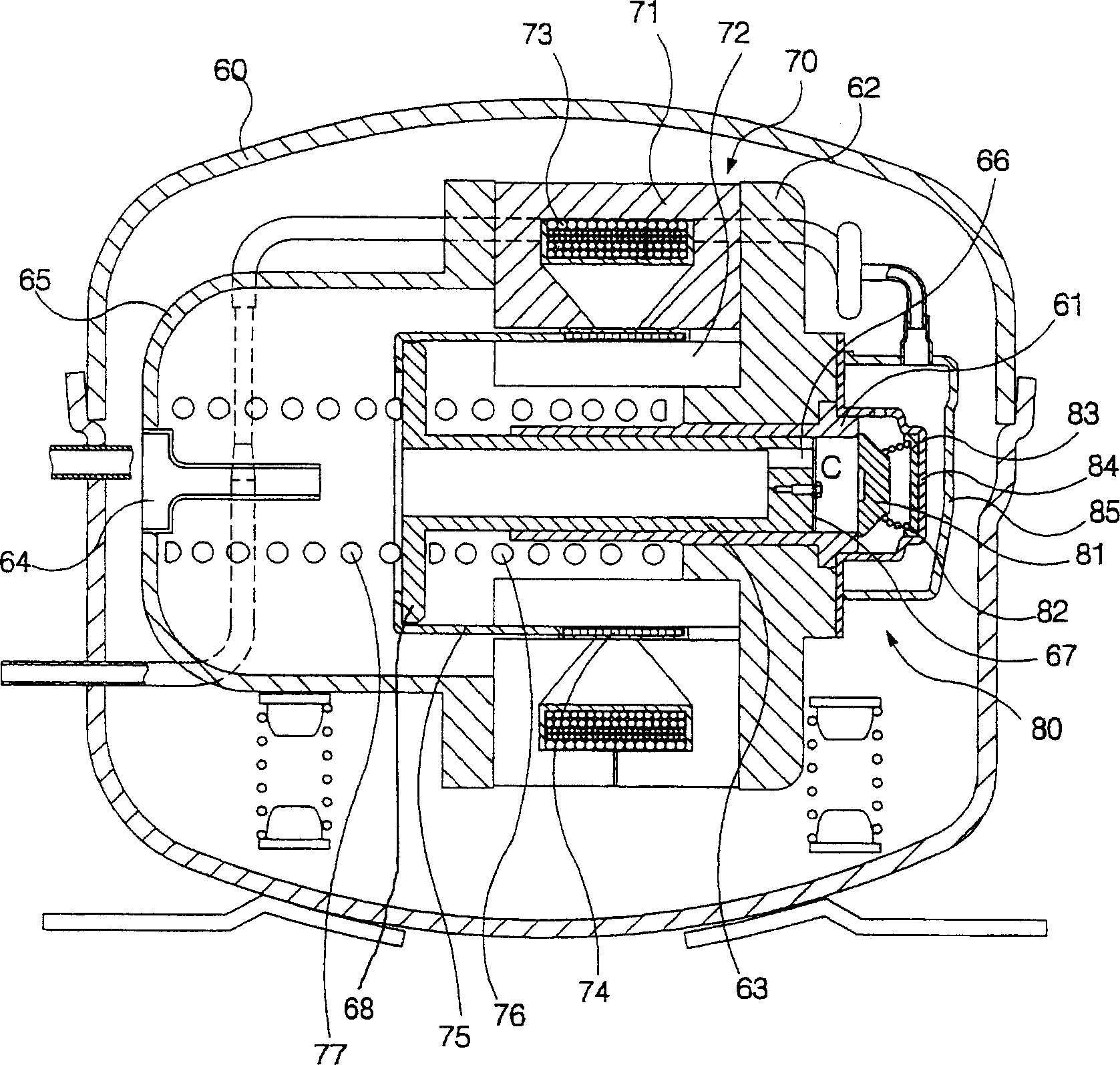

[0051] see Figure 3 to Figure 4 , the linear compressor according to the first embodiment of the present invention includes: a sealed casing 60; a linear motor 70 installed in the sealed casing 60; a cylinder block 62, which is arranged in the linear motor 70 and is provided with a cylinder 61; a piston 63 , which linearly reciprocates in the cylinder 61 by the linear motor 70 ; and a discharge member 80 , which is located in front of the opening of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com