Speed adjustable system for sorting work pieces based on one-track support

A sorting system and object technology, applied in the field of mail sorting systems, can solve the problems of difficult installation and debugging, high power consumption, high driving noise, etc., and achieve the effects of convenient installation and debugging, simple structure, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

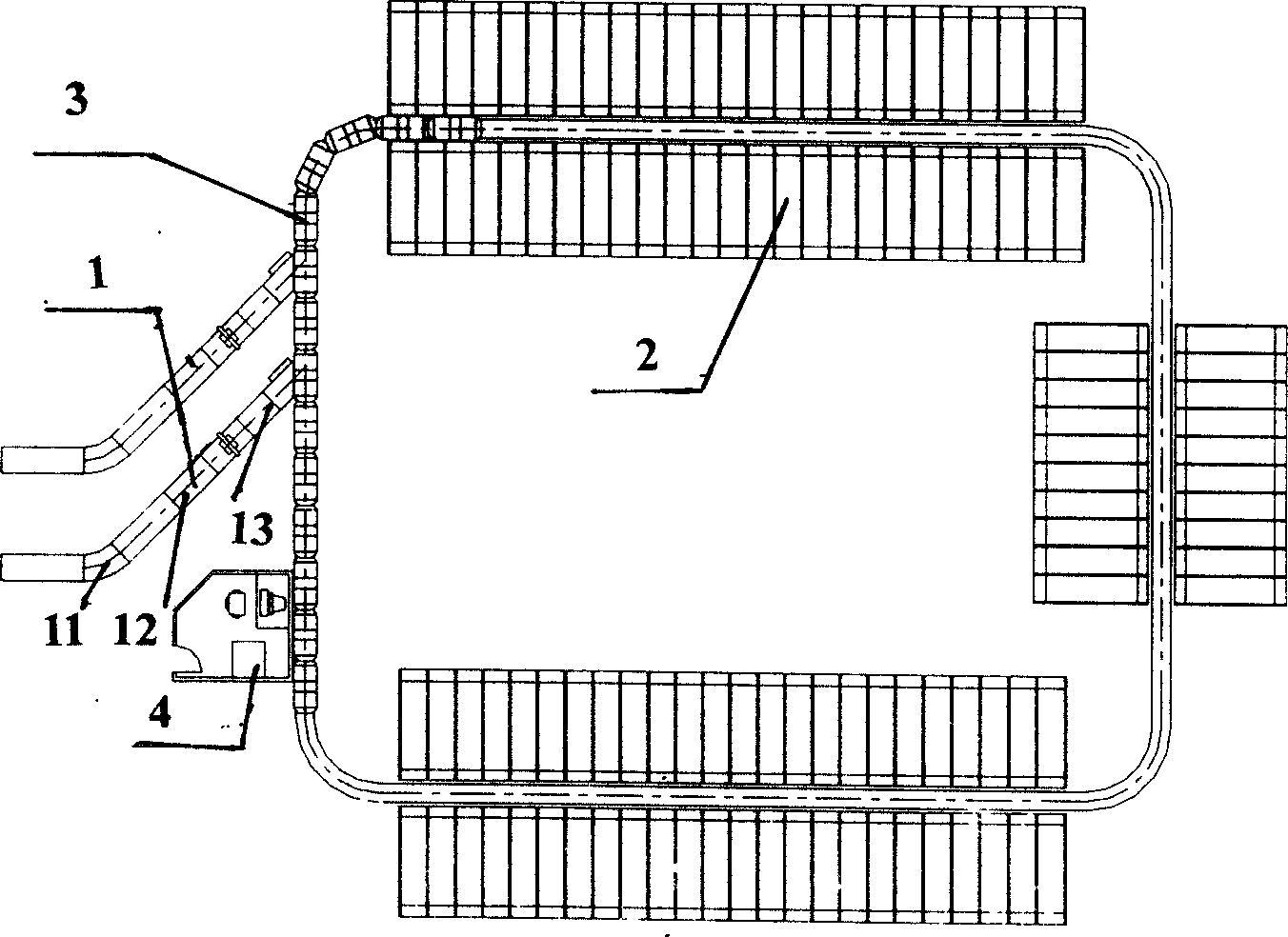

[0010] see figure 1 , the object sorting system of the present invention includes an object on-line module 1 , an object off-line module 2 and a circular conveying device 3 . Object on-line device 1 and object off-line device 2 are similar to existing ones. The object on-line device 1 is set as three independently driven belt lines: the first section is a conveying belt line 11 for conveying objects; the second section is a detection belt line 12, which can detect the length and width of an object by using optical signals such as optical cables , height and its location, and the detected information is sent to the computer control system 4; the third section is to control the upper bag conveying belt line 13, its main function is to weigh online, and it will detect the object weight information in real time Send to the computer control system 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com