Compressors muffler with resonance cavity

A technology of muffler and resonance cavity, which is applied in the direction of machine/engine, mechanical equipment, liquid fuel engine, etc., can solve the problems of poor muffler effect, poor muffler effect, and insignificant muffler effect, and achieve the effect of improving muffler effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The compressor muffler with resonant cavity of the present invention will be described with reference to the drawings and embodiments.

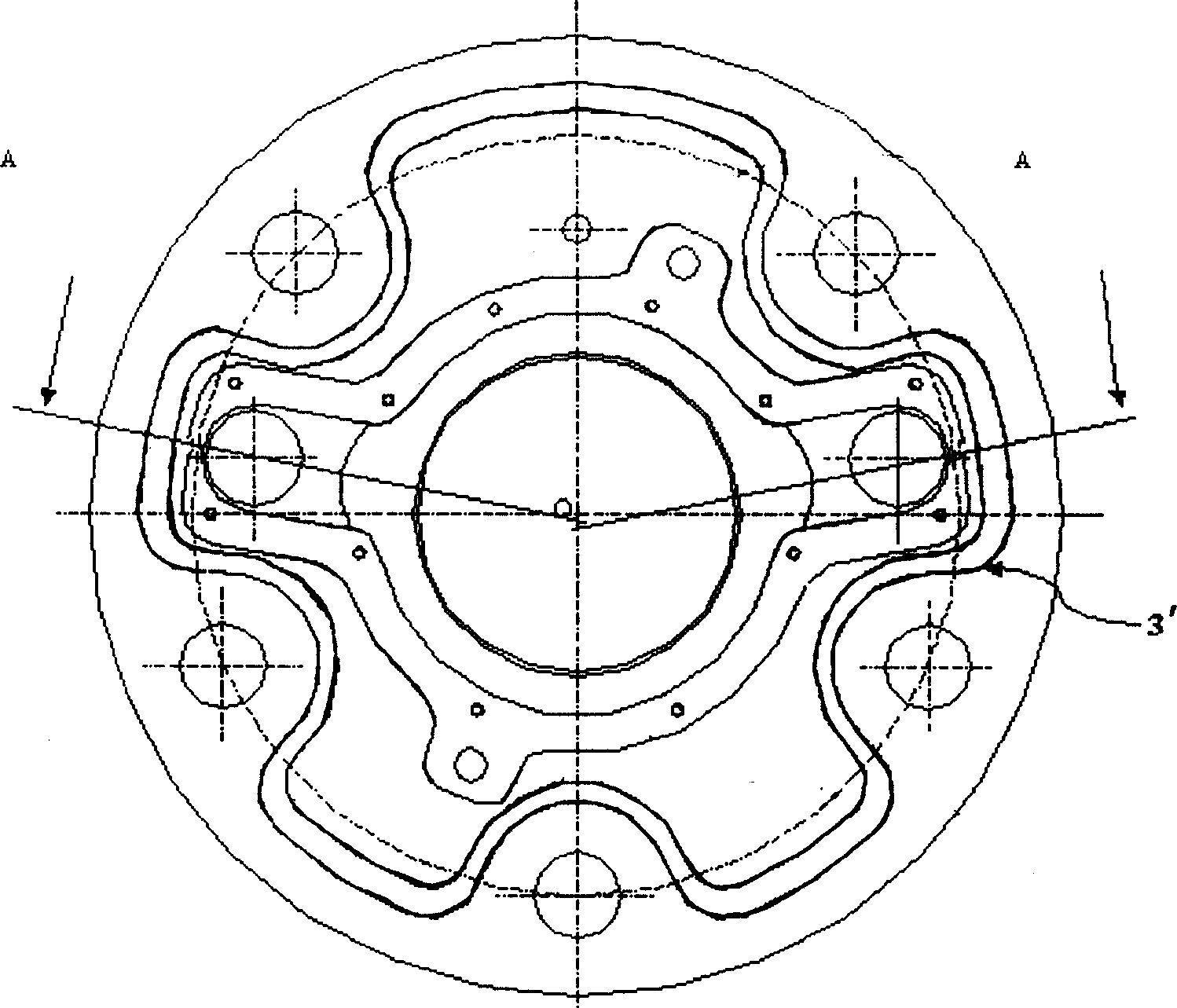

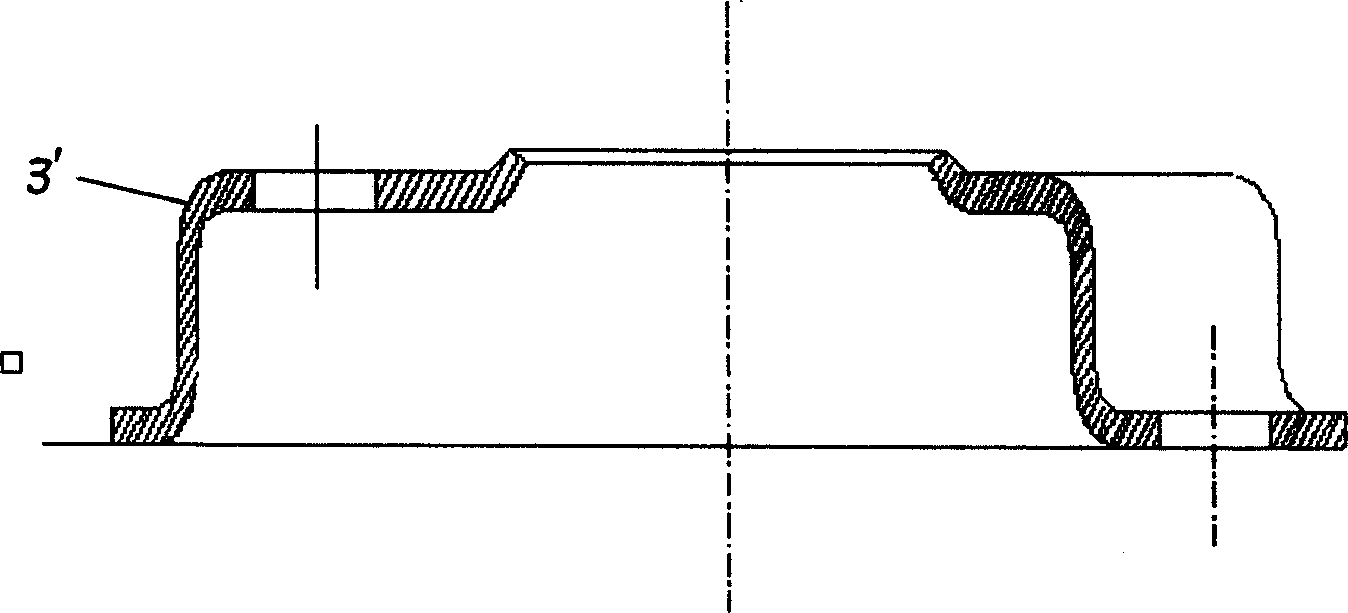

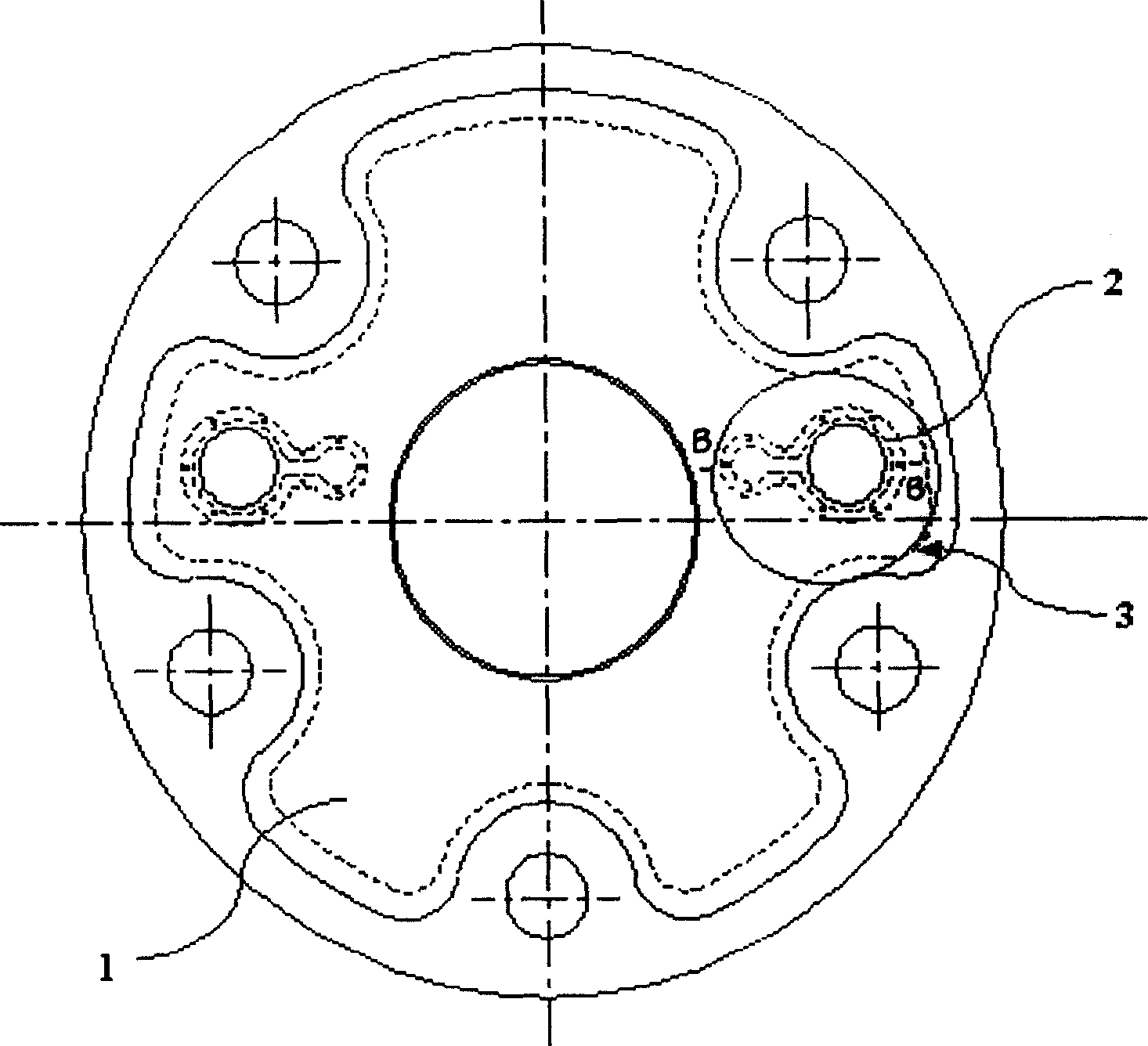

[0014] image 3 It is the bottom view of the compressor muffler of the present invention, Figure 4 yes image 3 The B-B section diagram. Such as image 3 , 4 As shown, the compressor muffler with resonant cavity of the present invention has a structure including a compressor muffler with a resonant cavity installed above the upper bearing with exhaust holes, and is respectively provided on both sides of the muffler central hole. The resonant cavities connected by connecting grooves, wherein one side of the resonant cavities close to the circumference are provided with exhaust holes.

[0015] The compressor muffler that the present invention has resonant chamber is realized like this:

[0016] Structurally, the present invention firstly changes the internal structure of the muffler of the compressor, and adds a resonant cavity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com