Balancing device with automatic pressure regulation

An automatic adjustment and balancing device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of affecting the authenticity and accuracy of diffusion experiments, affecting the accuracy of authenticity experiment results, and low degree of automation, so as to reduce manual work Quantity, improve the authenticity and accuracy, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following description only represents a specific embodiment of the present invention, and is only for further illustrating the present invention, but not limiting the present invention.

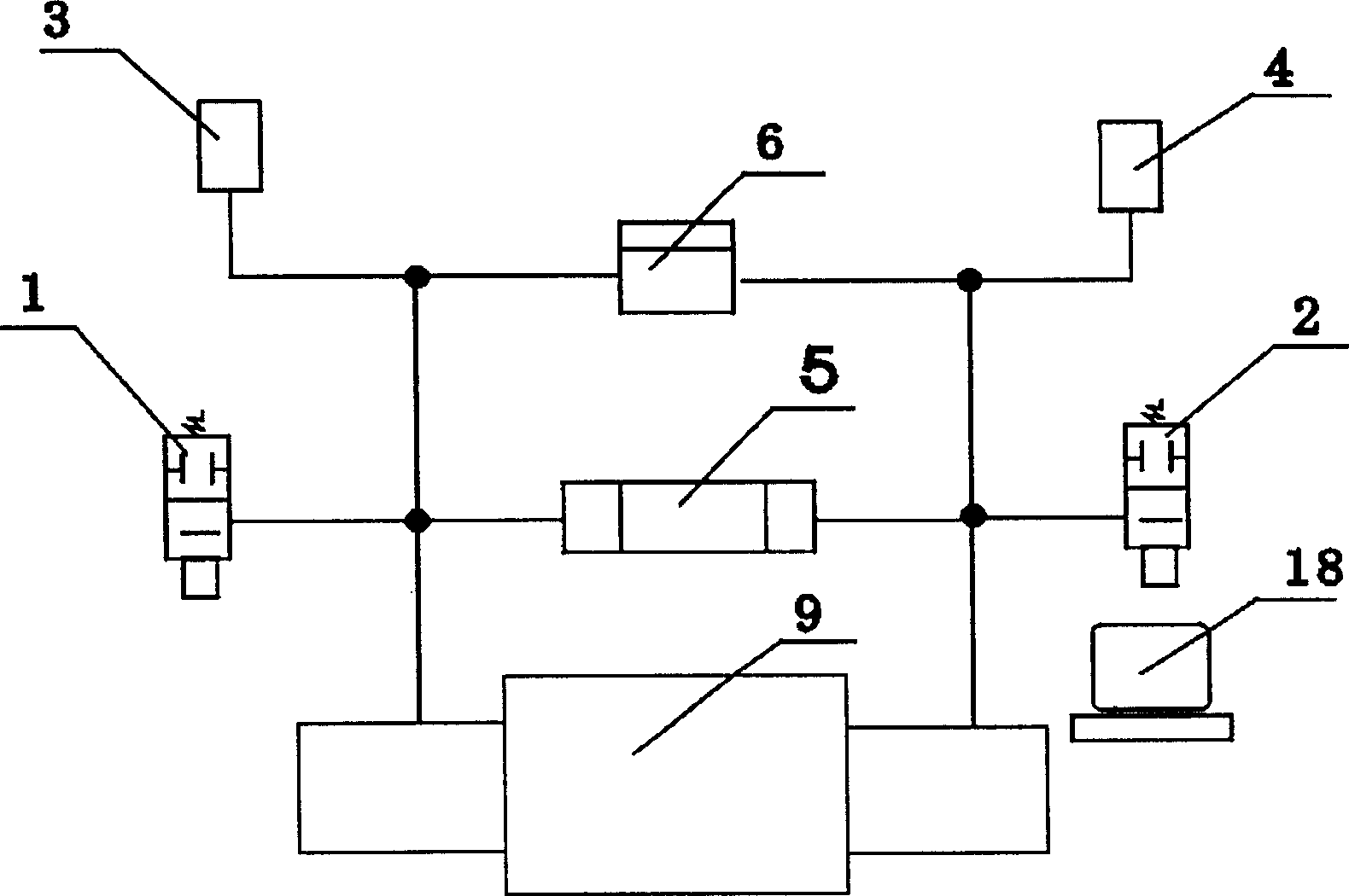

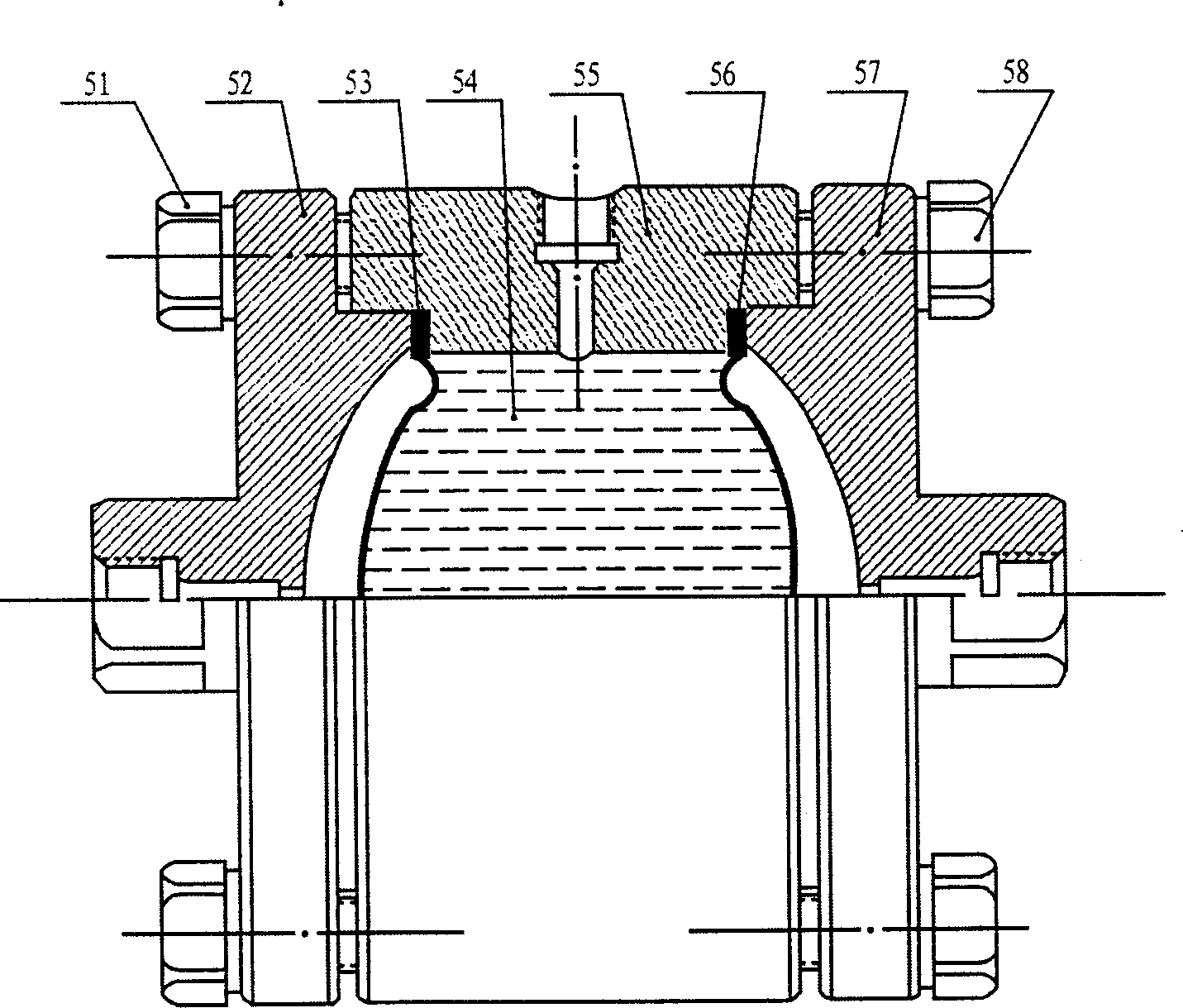

[0038] An automatic adjustment pressure balance device, including a computer 18, an air release valve 1, an air release valve 2, a pressure balance buffer 5, and a micro-pressure differential transmitter 6; wherein the pressure balance buffer 5 and the micro-pressure differential transmitter 6 The gas pipelines are connected in parallel, and one end of the parallel gas pipeline is connected with the purge valve 1, and the other end is connected with the purge valve 2.

[0039]The pressure bearing capacity of each component in the gas path of the device is not less than 5Mpa, and the temperature resistance is not less than 100°C. The two ends of the parallel gas pipeline are respectively connected to the two vents of the rock sample diffusion device 9, and are connected to the gas s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com