Handle fixing structure of vacuum cleaner

A vacuum cleaner and a fixed structure technology, applied in the direction of the handle, etc., can solve the problems that the handle 30 cannot be firmly fixed, the user cannot adjust the handle 30, and the length of the handle 30 cannot be adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

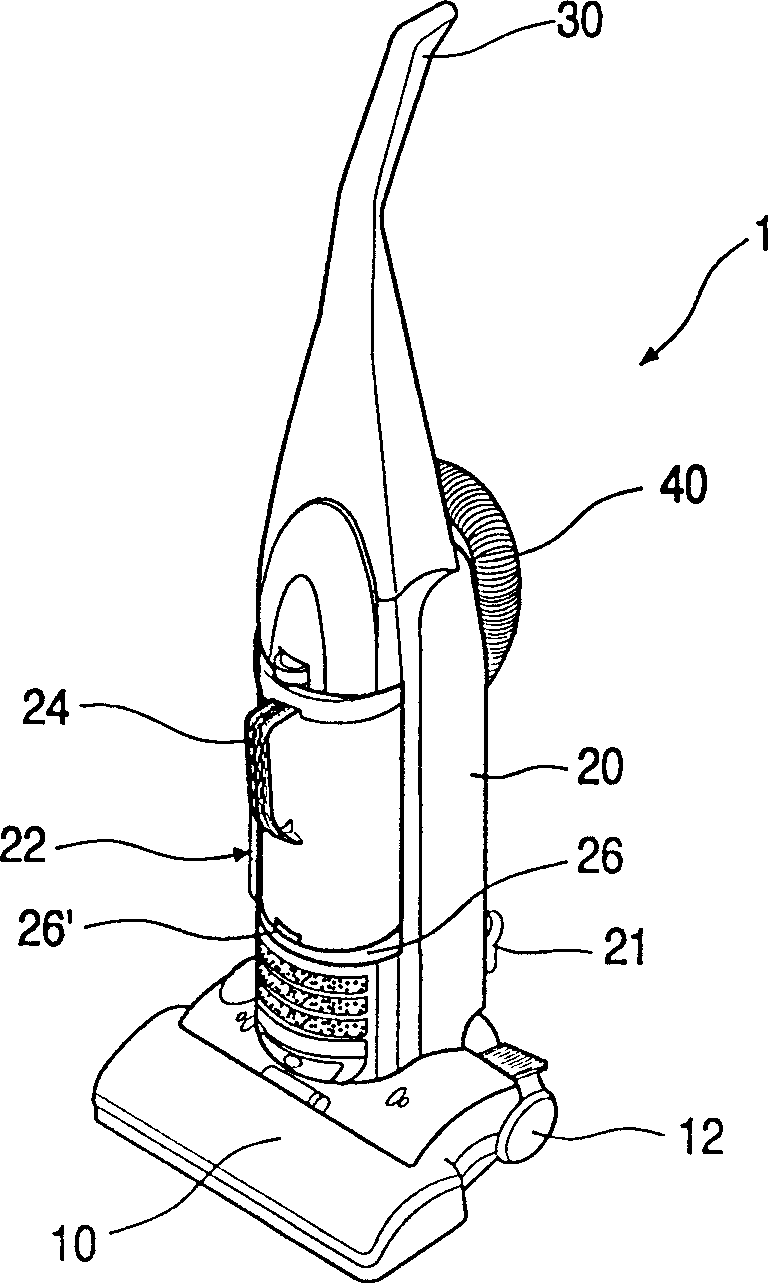

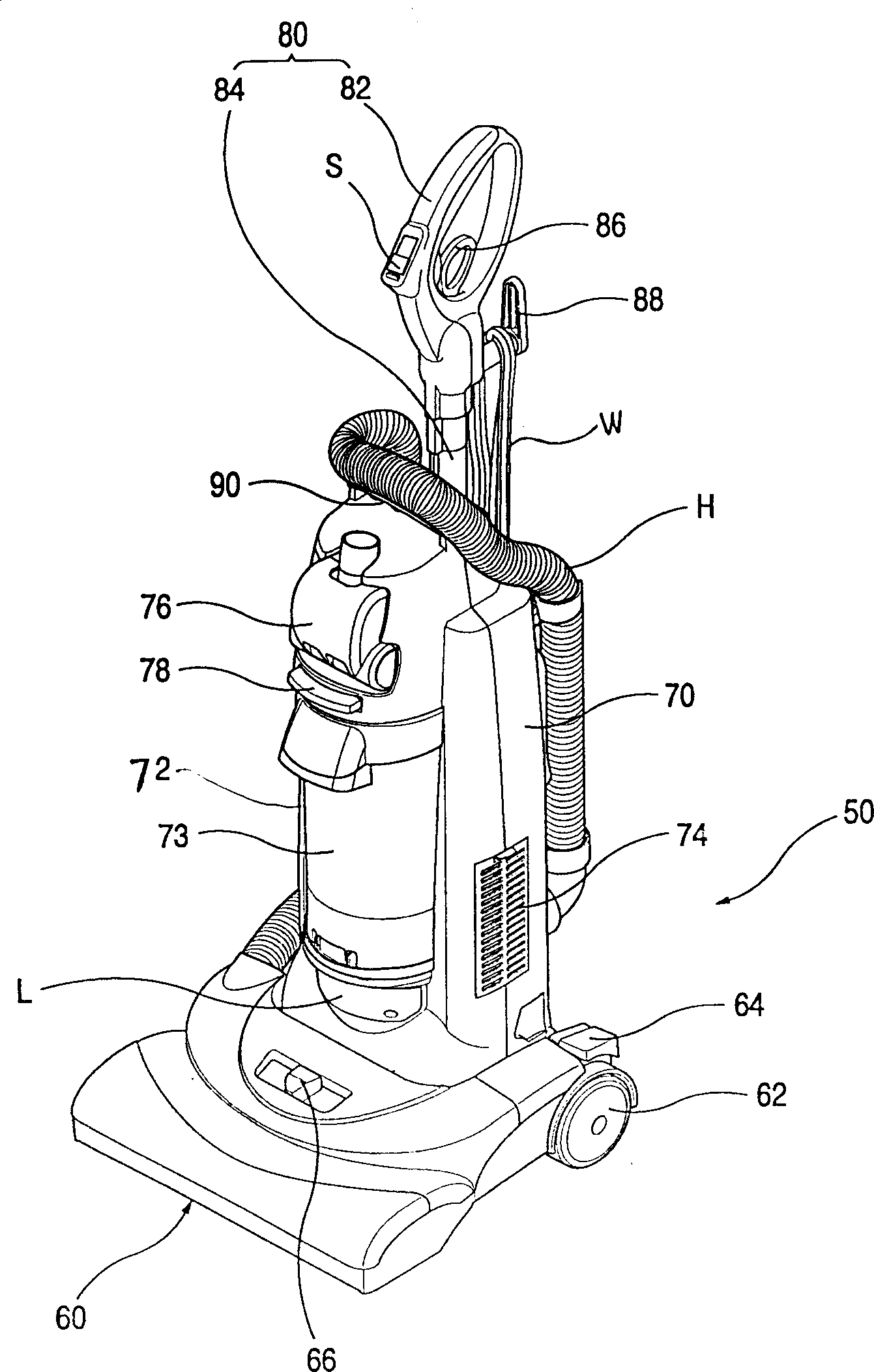

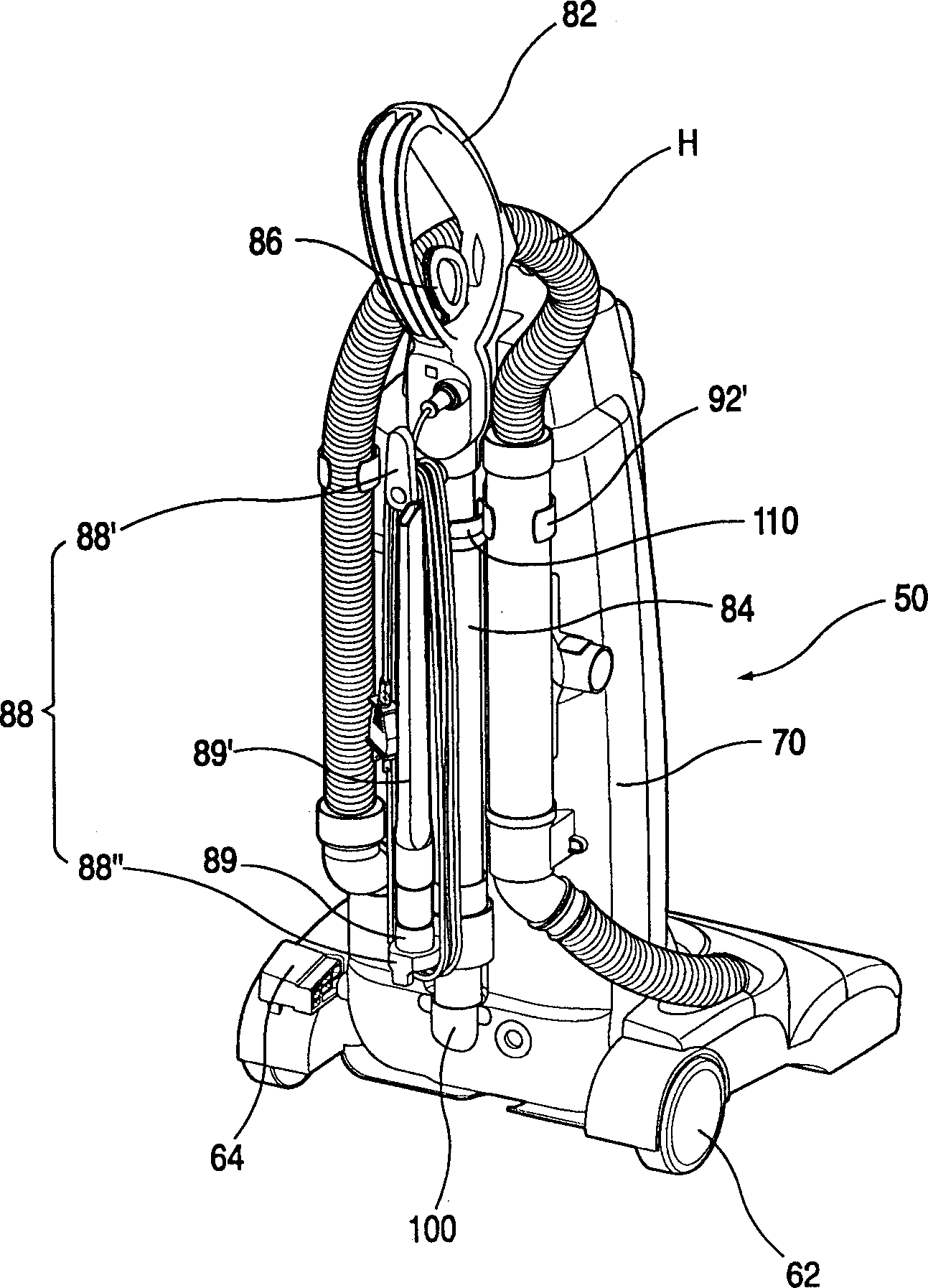

[0023] Such as figure 2 , 3 , 4, the upright vacuum cleaner 50 includes a suction head 60, a body 70 and a handle 80. Among them, the suction head 60 sucks air containing foreign matter while moving on the ground; the body 70 has a built-in device for generating suction force for sucking air containing foreign matter through the suction head 60; the handle 80 is equipped on the upper part of the body 70 so that the user can Easy to hold. The suction head 60 moves in a state close to the ground and sucks air through a suction port (not shown) on the bottom surface. The suction port of the external air main passage is formed on the bottom surface of the suction head 60 to guide the inflow of external air. In order to move the suction head 60 easily, moving wheels 62 are generally provided on both sides of the suction head 60 . The connecting portion of the suction head 60 and the body 70 forms a structure that can make the body 70 rotate within a certain angle range. Both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com