Bidirectional drive disc brake

A two-way drive and disc brake technology, applied to bicycle brakes, bicycle accessories, etc., can solve the problems of different degrees of wear, increase the consumption of manpower or electric energy, affect the durability of disc brakes, etc., and achieve the effect of eliminating axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

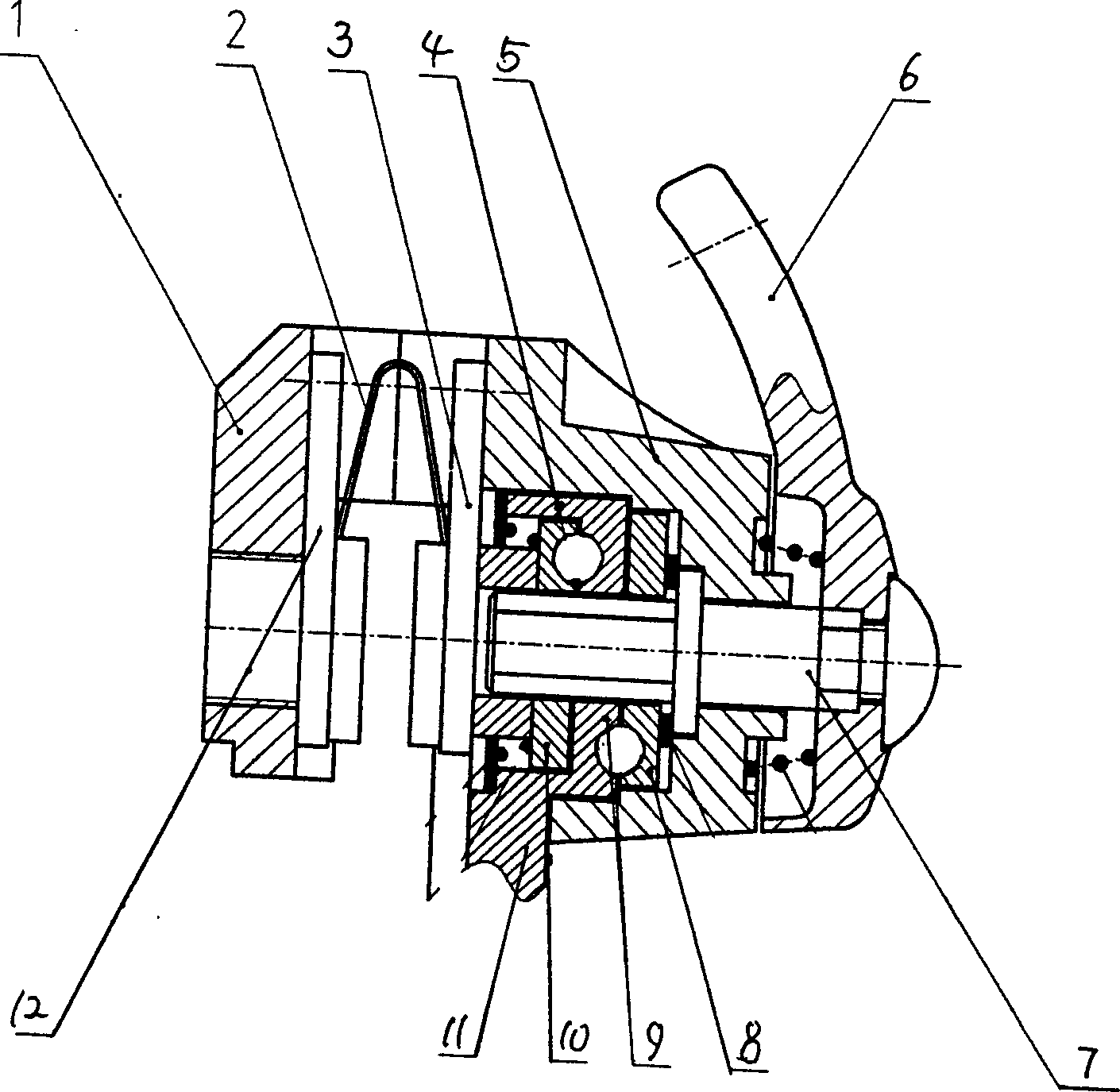

[0017] Embodiment 1, the two-way drive disc brake shown in Figure 1 and Figure 2 includes a disc brake disc and a brake caliper. 3-piece assembly, a V-shaped return leaf spring 2 is arranged between the two friction plate assemblies 12 and 3, one of the friction plate assemblies 12 is installed in the clamp arm 1, and the other friction plate assembly 3 is connected to the driving device, and the driving device The housing 5 and the pincer arm 1 are fixedly connected as one, and a fixed support frame 11 is provided at the jaw on one side of the driving device. The bosses 4 that slide and cooperate with each other, the bosses 4 are circular, cooperate with the inner cavity of the housing 5 to achieve center positioning, and can slide in the axial direction. In order to prevent relative rotation between the fixed support frame 11 and the housing 5, a limiting device is provided between the fixed supporting frame 11 and the housing 5, and the limiting device can adopt a structure...

Embodiment 2

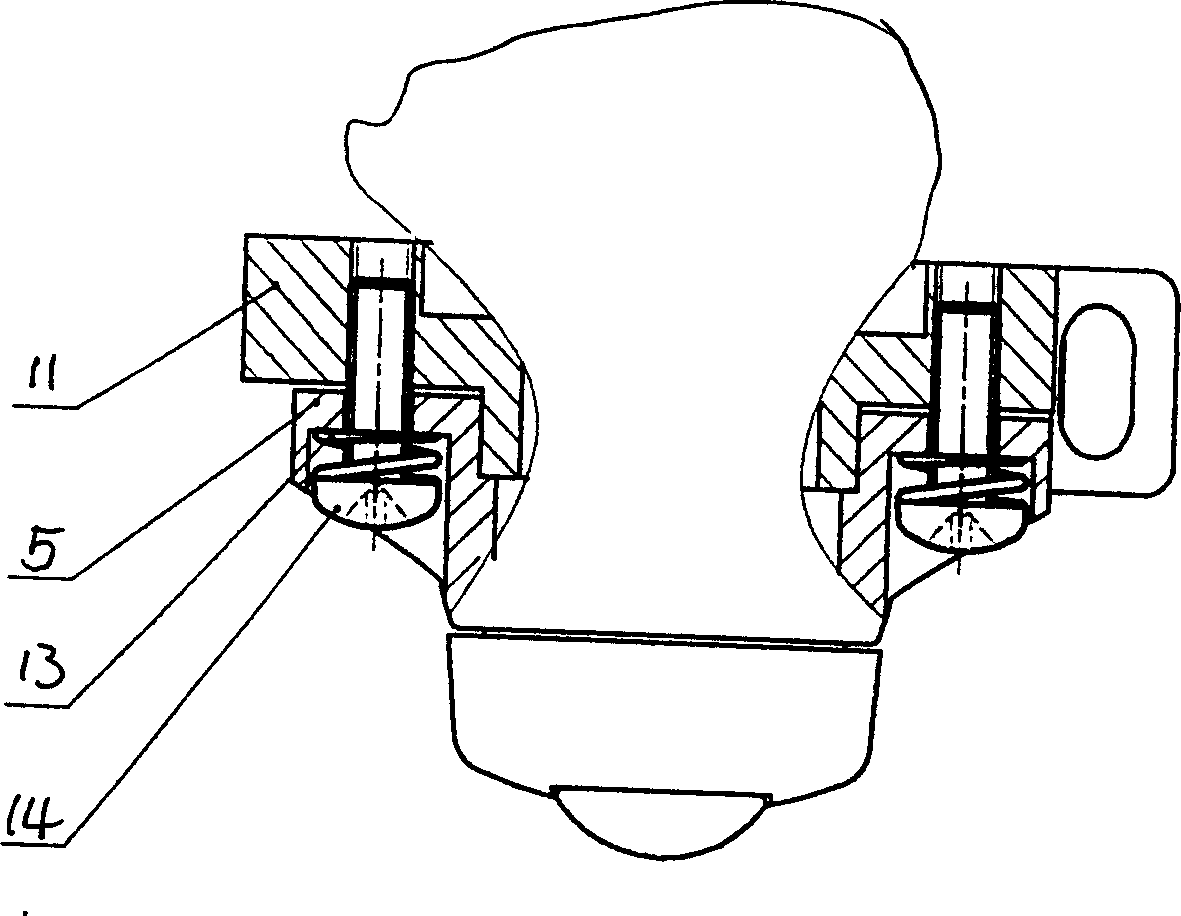

[0018] Embodiment 2, as shown in Figure 2, the inner surface of the casing 5 connected with the driving device is die-cast with a ball socket for accommodating steel balls 15, then the inner surface of the casing 5 forms a moving disk 8 that cooperates with the fixed disk 9, and the driving shaft 7 is connected to the fixed disk 9. Fixed disk 9 is connected to drive. This saves a moving disc part and reduces the overall volume of the disc brake caliper.

Embodiment 3

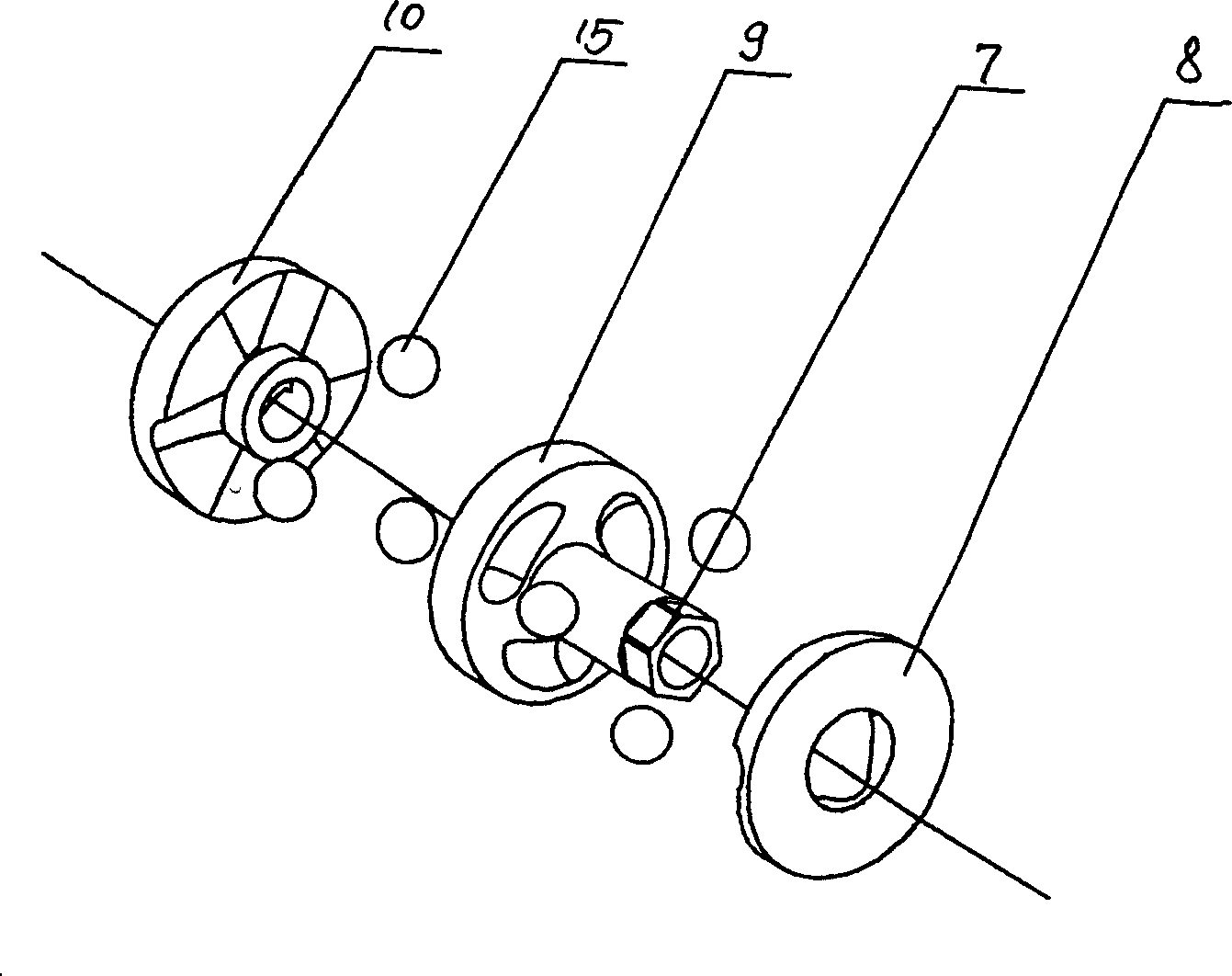

[0019] Embodiment 3, as shown in Figure 3, the drive shaft 7 is connected and driven with the fixed plate 9, and the disk surfaces of the two moving plates 8 and 10 are provided with 2 to 3 helical surfaces or spiral grooves corresponding to the surface of the fixed plate 9, and the fixed plate Steel ball 15 is housed between 9 and moving plate 8,10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com