Differential gearing

A transmission device and transmission system technology, applied in the direction of differential transmission device, transmission device, control device, etc., can solve the problems affecting the speed difference and achieve the effect of small rotating mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

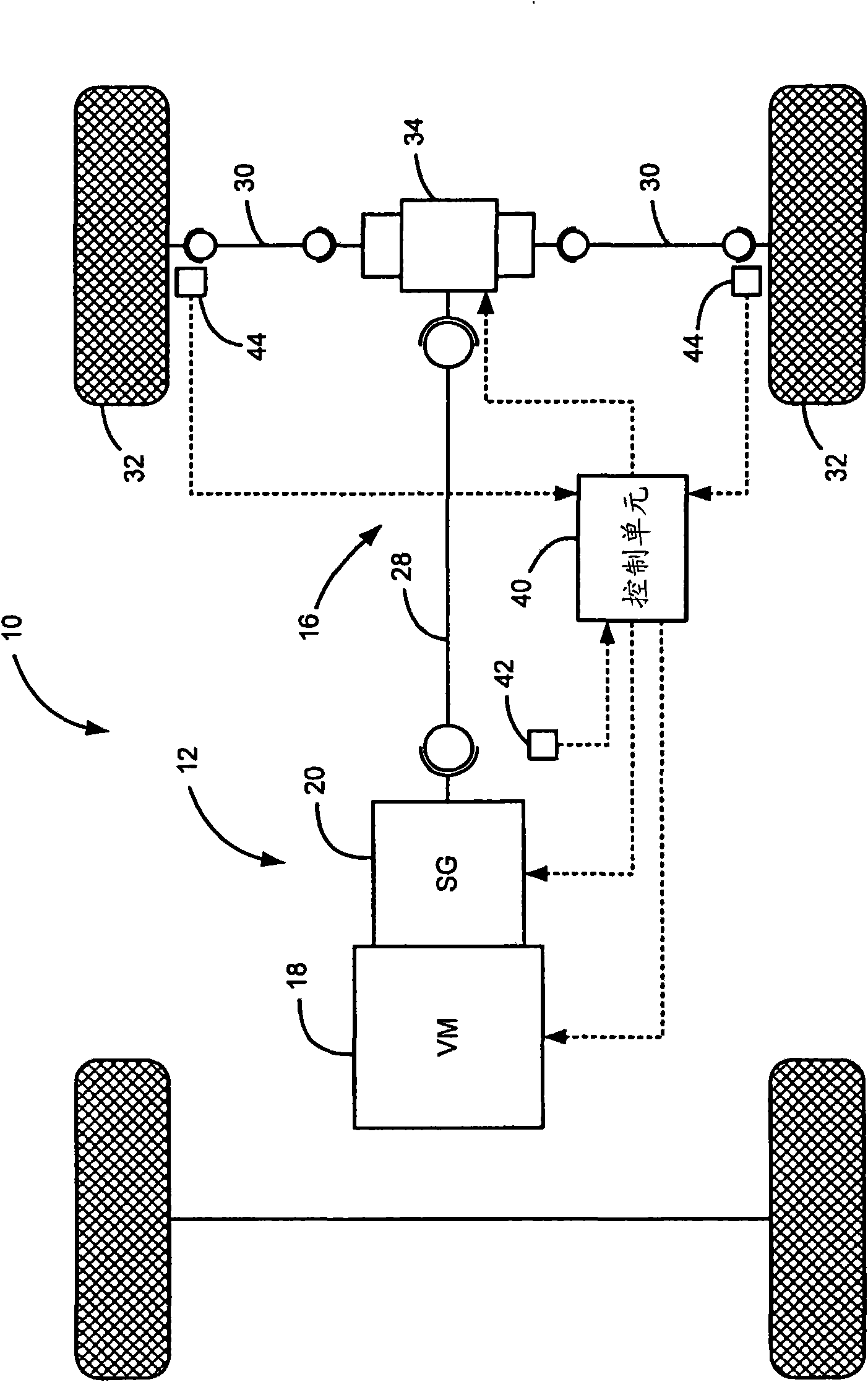

[0035] exist figure 1 An exemplary motor vehicle powertrain 10 is schematically shown in FIG. 2 , including a transmission 12 having a force transmission path 16 , an engine 18 and a transmission 20 . The force transmission path 16 includes a cardan shaft 28 driven through a transmission 20 , a pair of shafts 30 connected to a pair of wheels 32 , and a main drive 34 effective to transmit drive torque from the cardan shaft 28 to one or both shafts 30 . Although a vehicle driveline with rear drive is shown here by way of example, the invention can of course also be used in a vehicle driveline with front-wheel drive or all-wheel drive.

[0036] In order to achieve so-called "torque vectoring" driving (TV driving) and / or differential locking driving, the control unit 40 controls the operation of the main transmission 34 on the basis of a number of vehicle parameters. The control unit 40 is electronically connected to at least one sensor, preferably a plurality of sensors. Exemp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com