An ultra-thin strip rolling mill and its rolling method using back-up roll transmission

A technology of backup rolls and ultra-thin strips, used in metal rolling, metal rolling, metal rolling stands, etc., can solve the problems of pinion modulus, limited rolling mill thinning capacity, torsional vibration, etc., and achieve different speeds. Smaller than the variation step, the rolling thickness range is increased, and the effect of reducing the torsional vibration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

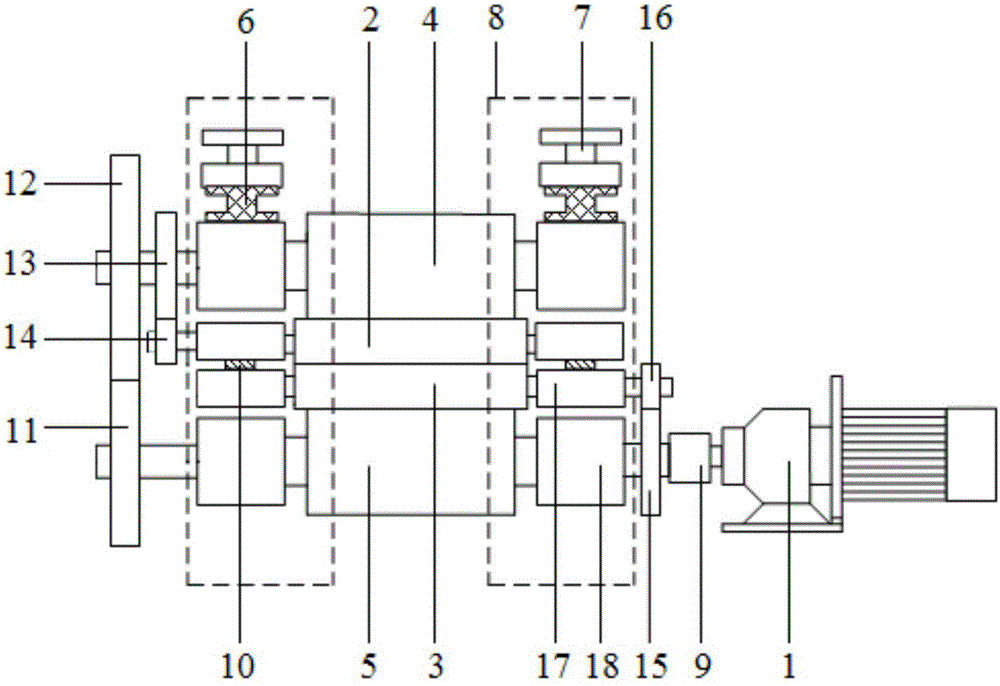

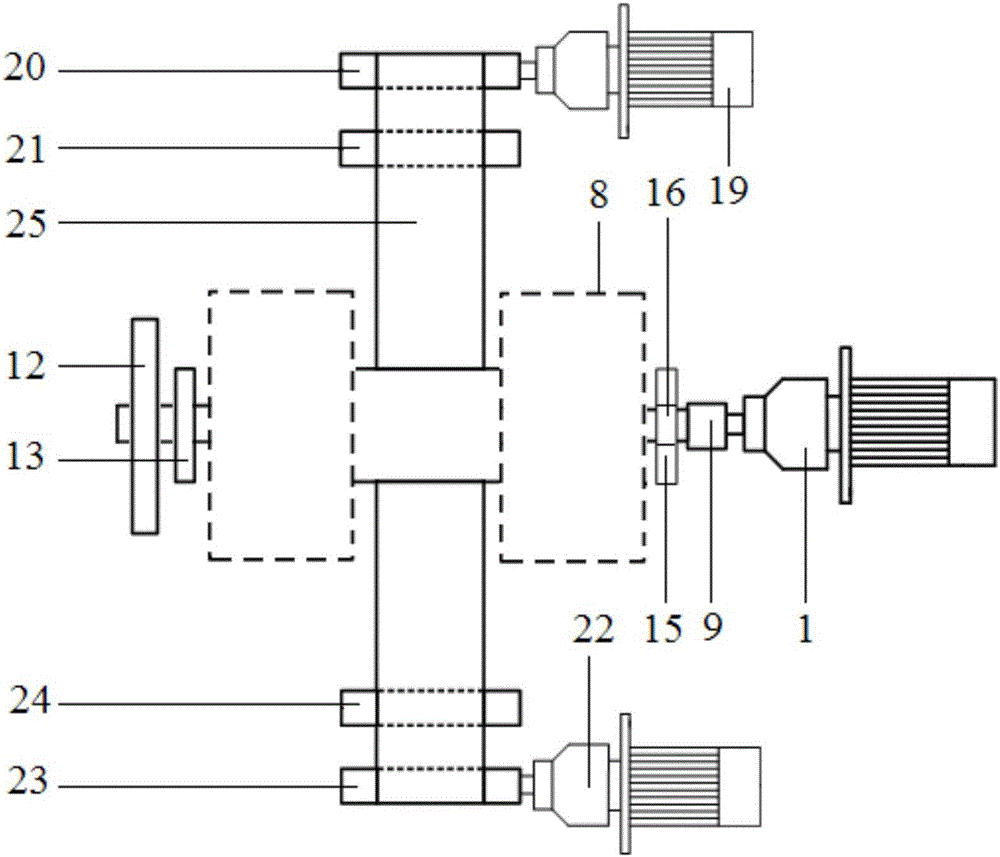

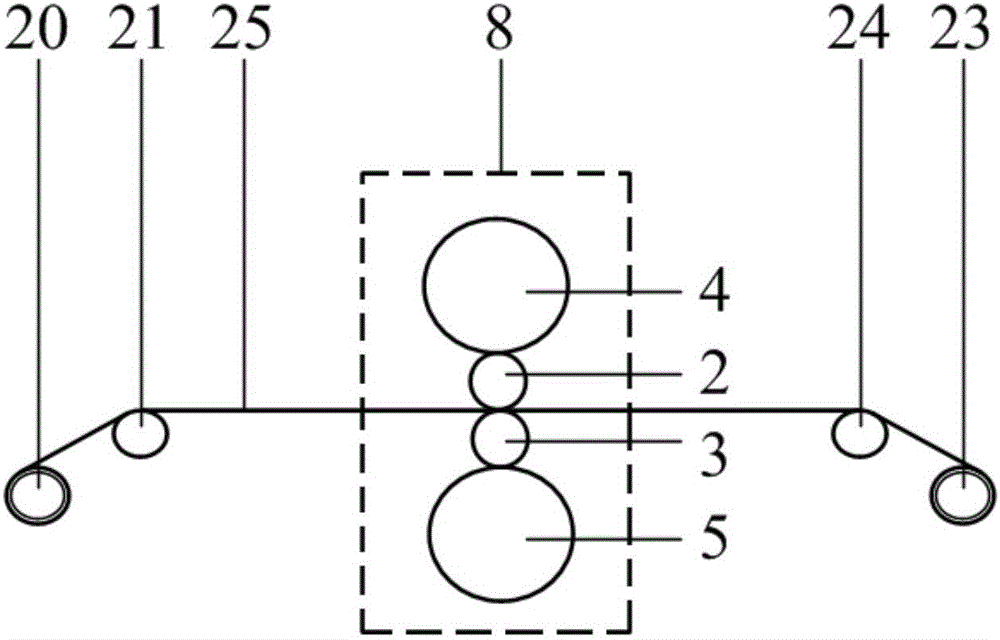

[0036] Such as figure 1 , 2 As shown, an ultra-thin strip rolling mill driven by a support roll includes a main drive motor 1, a work roll, a support roll, a pressing device 7, a housing 8, a first tension motor 19, and a second tension motor 22. The roll includes an upper work roll 2 and a lower work roll 3. The support roll includes an upper support roll 4 and a lower support roll 5. The upper work roll 2 and the lower work roll 3 are both slidably connected to the archway 8 through the work roll bearing seat 17, and the upper The support roller 4 is fixed in the window of the archway 8 by the support roller bearing seat 18, and the lower support roller 5 is fixed on the bottom of the archway 8 by the support roller bearing seat 18, between the upper work roll 2 and the work roll chock 17 of the lower work roll 3. A thrust spring 10 is installed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com